2025 Guide: How to Choose and Install a Dc-Link Busbar Effectively

Table of Contents

- Choosing the Right DC-Link Busbar for Your Project

- Understanding the Specifications of DC-Link Busbars

- Key Considerations for Installation Location and Layout

- Necessary Tools and Equipment for Installation

- Step-by-Step Installation Process for DC-Link Busbars

- Common Mistakes to Avoid When Installing Busbars

- Maintenance Tips for Ensuring Long-Term Performance

- Innovative Applications and Benefits of D370 SMC Molded Insulation Sheets in Modern Industries

- FAQS

- Conclusion

- Related Posts

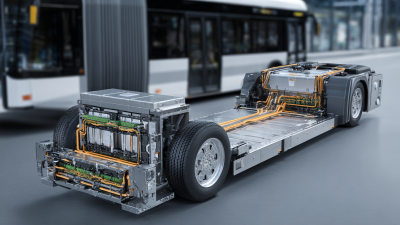

In the world of power electronics, things are moving fast, and it's pretty clear that having an efficient busbar system is a big deal. You see, the DC-Link Busbar is pretty much the backbone when it comes to connecting different power components inside converters and inverters. If it’s not up to the mark, your system’s performance and reliability can suffer. As John Smith, a well-known expert in power distribution from PowerTech Solutions, put it nicely, “Choosing the right Dc-Link Busbar and installing it properly can really make or break the efficiency and safety of your entire power system.”

Picking out the perfect Dc-Link Busbar isn't just about grabbing whatever’s available. You gotta consider what your specific setup needs—like how much current it needs to handle, how it manages heat, and how sturdy it needs to be. Thanks to new materials and smarter designs coming out all the time, it’s more important than ever for engineers and techs to stay in the loop with best practices. Also, installing these busbars isn’t just about technical know-how; you’ve got to be pretty familiar with electrical safety standards, too, so you don’t run into avoidable hazards.

This guide’s here to help you understand what to look for when choosing and installing a Dc-Link Busbar. By following these tips, you’ll make sure your power systems are not just efficient but also reliable. That way, you're all set to support sustainable energy solutions for the future.

Choosing the Right DC-Link Busbar for Your Project

When selecting the right DC-Link busbar for your project, it's essential to consider several key factors that will impact the overall performance and efficiency of your electrical system. First and foremost, you need to assess the current and voltage ratings specific to your application. This ensures that the busbar can handle the electrical load without overheating or causing failure.

Additionally, evaluating the environmental conditions where the busbar will be installed is crucial. Variables such as temperature, humidity, and potential exposure to corrosive elements will dictate the choice of materials and insulation properties.

Another critical aspect is the physical design of the DC-Link busbar. It should not only fit within the space constraints of your installation but also allow for proper heat dissipation. The geometry and layout must facilitate efficient connections to other components while minimizing electrical losses. Furthermore, consider the installation ease and maintenance requirements. A busbar that allows for straightforward assembly and accessibility will save time and resources in the long term. Ultimately, a thoughtful selection process will yield a reliable and cost-effective solution tailored to your project's unique needs.

Understanding the Specifications of DC-Link Busbars

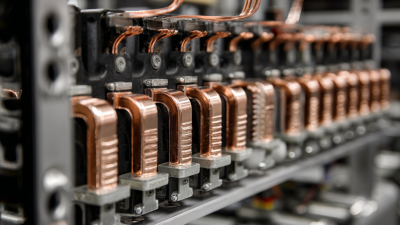

When selecting a DC-Link busbar, understanding its specifications is crucial for ensuring optimal performance in your electrical system. DC-Link busbars serve as vital connections between various components, providing a low-resistance path for DC currents. Key specifications to consider include the material used, typically copper or aluminum, which impacts both conductivity and thermal performance. The cross-sectional area is another critical factor; a larger cross-section can decrease resistive losses and enhance overall efficiency, but it may also necessitate additional space and weight considerations in the design.

Another important specification is the voltage rating, which determines the maximum permissible operating voltage of the busbar. It is essential to choose a busbar with a voltage rating that exceeds the operational needs of your application to ensure safety and reliability. Additionally, evaluating the thermal characteristics is vital, as the busbar must withstand the heat generated by current flow without degradation. Proper insulation and surface treatments can also enhance performance and longevity, particularly in high-temperature environments. By thoroughly understanding these specifications, you can make informed decisions that contribute to the performance and reliability of your DC electrical systems.

2025 Guide: How to Choose and Install a Dc-Link Busbar Effectively - Understanding the Specifications of DC-Link Busbars

| Specification | Description | Typical Values | Considerations |

|---|---|---|---|

| Material | The material used for busbars affects conductivity and thermal management. | Copper, Aluminum | Choose based on conductivity requirements and cost. |

| Current Rating | The maximum continuous current that the busbar can carry without overheating. | 100A, 200A, 400A | Ensure it matches the application needs. |

| Voltage Rating | The maximum voltage that can be safely handled. | 600V, 1000V | Select based on system maximum voltage. |

| Busbar Size | Physical dimensions of the busbar, impacting installation and space. | Custom sizes available | Consider space constraints in installation area. |

| Insulation Type | Material used for insulating the busbars to prevent electrical shorts. | Epoxy, PVC | Choose based on environmental conditions. |

Key Considerations for Installation Location and Layout

When choosing an installation location for a DC-Link busbar, several key factors should be taken into account to ensure optimal performance and safety. First, the environment must be suitable, meaning that the area should be dry, dust-free, and away from corrosive substances that could degrade the busbar material over time. Adequate ventilation is also crucial, as it helps dissipate heat generated during operation, which can otherwise lead to failures or reduced efficiency.

Next, the layout of the installation site should facilitate easy access for maintenance and inspection. It is important to configure the busbar system in a manner that minimizes connections and potential points of failure. This can involve careful planning of both horizontal and vertical space in relation to other electrical components. Additionally, ensure that the busbar installation aligns with other system architectures, allowing for efficient wiring and reducing electromagnetic interference. Proper planning not only enhances operational reliability but also extends the lifespan of the equipment, ultimately leading to better system performance.

Necessary Tools and Equipment for Installation

When considering the installation of a DC-link busbar, it's crucial to equip yourself with the necessary tools and equipment to ensure a smooth and effective process. First and foremost, you will need reliable hand tools, including a wire stripper and crimping tool to prepare connections securely. A torque wrench is essential for applying the proper tension to bolt connections, preventing future loosening which could lead to performance issues. Additionally, insulated screwdrivers and pliers should be on hand to safely manage component installation.

Safety equipment is equally important during installation. Personal protective gear such as gloves and safety glasses should be worn to protect against electrical hazards. A multimeter will also be beneficial for checking voltage levels and ensuring proper connections before powering up the system. Furthermore, plan for adequate workspace tools, such as a sturdy workbench and chop saw for cutting aluminum or copper busbars to the required lengths. With the right tools and safety measures in place, the installation process can be executed with increased efficiency and safety, ultimately leading to optimal performance of your DC-link busbar system.

Step-by-Step Installation Process for DC-Link Busbars

Installing a DC-Link busbar requires careful planning and execution to ensure optimal performance and safety. The first step in the installation process is to analyze the system requirements and select the appropriate busbar specifications based on voltage, current ratings, and short-circuit strength. Once these specifications are determined, it is crucial to prepare the installation site by ensuring a clean and dry environment. Proper clearance and insulation are essential to prevent potential electrical hazards.

Next, the actual installation begins with securely mounting the busbar in its designated location. This typically involves aligning the busbar with pre-identified anchoring points on the mounting structure. Utilizing appropriate tools, the busbar should be fastened using bolts that meet the recommended torque specifications. It is also important to ensure that all connections are made tight and that compatible materials are used to avoid corrosion. After the mechanical installation, electrical connections are established. This includes connecting the busbar to various components within the system, following a carefully mapped wiring schema to maintain system integrity and functionality.

Common Mistakes to Avoid When Installing Busbars

When installing a DC-Link busbar, avoiding common mistakes is crucial to ensuring both safety and efficiency in electrical systems. One of the frequent pitfalls is inadequate planning. Failing to thoroughly assess the electrical load, ambient conditions, and necessary specifications can lead to improper sizing and unexpected failures. Take the time to calculate the total current carrying capacity needed, considering future expansions.

Another common mistake is neglecting proper grounding. A well-grounded busbar system is essential for protecting against faults and ensuring system stability. Ensure that all connections are secure and that grounding electrodes are appropriately installed. Ignoring these aspects can result in increased risk of electrical shock or system failures.

**Tips:** Always double-check your measurements and make sure your installation complies with local electrical codes. Familiarize yourself with best practices regarding the layout and support structures needed to minimize electromagnetic interference. Implementing these simple strategies can vastly improve the reliability and performance of your busbar system.

Maintenance Tips for Ensuring Long-Term Performance

Maintaining a DC-link busbar is crucial for ensuring its longevity and reliability in electrical systems. Regular inspection is essential; check for signs of wear, oxidation, or any potential overheating. It is advisable to create a maintenance schedule that includes visual inspections, thermal imaging, and electrical testing at regular intervals. Keeping the insulation and connections clean and secure helps prevent shorts or failures, which can lead to costly downtime.

In addition to inspections, proper environmental control is important for the busbar's performance. Ensure that the installation area is free from moisture, dust, and corrosive agents. Utilizing protective coatings can further shield the busbar from environmental factors that can accelerate deterioration. Implementing routine cleaning protocols, such as using appropriate solvents for grime and residue removal, can enhance the overall operational effectiveness of the busbar. By prioritizing these maintenance tips, you can significantly extend the lifespan of the DC-link busbar and ensure consistent performance in your electrical system.

Innovative Applications and Benefits of D370 SMC Molded Insulation Sheets in Modern Industries

The D370 SMC molded insulation sheets, classified under the D&F type number DF370, represent an innovative advancement in insulation technology. These thermosetting rigid insulation sheets are manufactured from sheet molding compound (SMC) using a high-temperature and high-pressure molding process. This method not only enhances their structural integrity but also ensures they meet rigorous industry standards, including UL certification and compliance with REACH and RoHS regulations.

The unique composition of SMC, which incorporates glass fiber reinforced unsaturated polyester resin along with fire retardants, provides exceptional thermal resistance and mechanical strength. Recent industry reports indicate that the use of advanced insulation materials like the D370 SMC sheets can improve energy efficiency in various applications, reducing operational costs by up to 20%. Additionally, their fire-retardant properties are critical in protecting structures and minimizing risks, making them an ideal choice for modern industrial applications, including automotive, construction, and electrical sectors.

Furthermore, the versatility of D370 SMC molded insulation sheets allows for customized solutions tailored to specific operational demands. As industries increasingly prioritize sustainable practices, the durability and longevity of these insulation sheets contribute to reduced material waste and lower maintenance costs over time. This innovative application not only enhances operational efficiency but also supports companies in achieving their environmental goals.

FAQS

: Key factors include current and voltage ratings, environmental conditions, physical design, heat dissipation, installation ease, and maintenance requirements.

Assessing current and voltage ratings ensures the busbar can handle the electrical load without overheating or failing, thereby maintaining system safety and reliability.

Environmental conditions such as temperature, humidity, and exposure to corrosive elements influence the choice of materials and insulation properties for the busbar.

The physical design must fit the installation space, allow for proper heat dissipation, and facilitate efficient connections to minimize electrical losses.

The material, typically copper or aluminum, directly impacts conductivity and thermal performance, affecting overall system efficiency.

A larger cross-sectional area can reduce resistive losses and improve efficiency, but it may require more space and increase weight.

The voltage rating determines the maximum operating voltage; selecting a busbar with a rating exceeding operational needs ensures safety and reliability.

The busbar must withstand heat generated by current flow without degradation, and proper insulation and surface treatments enhance its performance in high-temperature environments.

A busbar that allows for straightforward assembly and accessibility can save time and resources during installation and maintenance.

Understanding specifications and selecting the right busbar can enhance the performance, reliability, and cost-effectiveness of DC electrical systems.

Conclusion

The article "2025 Guide: How to Choose and Install a Dc-Link Busbar Effectively" provides a comprehensive overview of the key aspects involved in selecting and installing a DC-Link busbar for various projects. It emphasizes the importance of understanding the specifications of DC-Link busbars, including their voltage and current ratings, to ensure compatibility with specific applications. The guide also outlines critical factors to consider when determining the installation location and layout, ensuring the busbars are placed in optimal positions for performance and accessibility.

In addition to detailing necessary tools and equipment for installation, the article presents a step-by-step process that simplifies the installation of DC-Link busbars. It highlights common mistakes to avoid during installation, which can enhance safety and efficiency. Finally, the guide offers maintenance tips to ensure the long-term performance of DC-Link busbars, helping users maximize their investment over time.

Related Posts

-

Identifying Challenges with Electric Vehicle Busbar Innovations

-

How to Achieve a Durable Finish with Epoxy Bus Coating Techniques

-

How to Choose the Right Flexible Copper Strip for Optimal Electrical Performance

-

5 Best Insights into Gpo 3 Specifications for Optimal Performance

-

Global Market Insights: Projecting the Future of Best Epoxy Fiberglass Tubes by 2025

-

Solutions for Enhancing Electrical Efficiency with Silver Plated Copper Bus Bars