Unlocking the Advantages of Bare Copper Strip in Electrical Applications for Energy Efficiency

Table of Contents

- Benefits of Using Bare Copper Strips for Enhanced Energy Efficiency in Electrical Applications

- Understanding the Thermal Conductivity of Bare Copper Strips versus Other Materials

- Applications of Bare Copper Strips: Maximizing Energy Transfer in Electrical Systems

- Cost-Effectiveness of Bare Copper Strips in Long-Term Electrical Infrastructure

- Industry Standards and Compliance for Utilizing Bare Copper Strips in Electrical Projects

- Innovative Technologies Integrating Bare Copper Strips for Improved Electrical Performance

- Maximizing Efficiency with China High Quality Laminated Bus Bar: A Comprehensive Guide to Benefits and Applications

- FAQS

- Related Posts

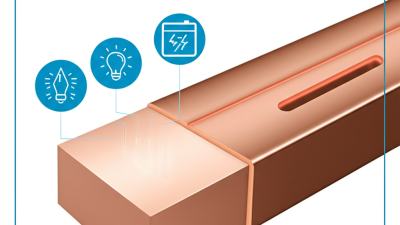

When it comes to boosting energy efficiency and making electrical setups work smoothly, using top-notch materials is a total game-changer. One material that’s really been making waves in the industry is the Bare Copper Strip—especially from companies like Sichuan D&F Electric Co., Ltd. Founded back in 2005 and based right in Deyang, Sichuan, China, D&F Electric has built a solid reputation as a dependable provider of electrical connection parts and insulation components. The real big advantage of Bare Copper Strips? Their excellent conductivity, durability, and reliable connections—they’re key to improving how energy is used in electrical systems. In this blog, we’ll dig into the many benefits of Bare Copper Strips made in China, highlighting why they’re so important in today’s electrical applications—and what sets D&F Electric’s products apart in a pretty crowded market.

Benefits of Using Bare Copper Strips for Enhanced Energy Efficiency in Electrical Applications

Bare copper strips are really catching on in the electrical world, mainly because they help make systems more energy-efficient. One of the biggest perks of using bare copper is how great it is at conducting electricity. This means there's very little resistance, so less energy gets lost along the way. When you put in copper strips like these, your setups tend to run better and use less power — which, in the long run, saves you money and is better for the planet, too.

But it’s not just about conductivity. These copper strips are super durable and resist corrosion, so they hold up well even in tough environments. That kind of toughness means fewer repairs or replacements, which again, keeps energy use in check over time. Plus, since bare copper is so easy to shape and connect, it opens up a lot of cool possibilities for designing smarter layouts in electrical systems. All in all, as industries push for greener and more efficient practices, switching to bare copper strips could be a smart move to boost energy efficiency across different kinds of electrical applications.

Understanding the Thermal Conductivity of Bare Copper Strips versus Other Materials

When it comes to electrical stuff, the thermal conductivity of bare copper strips is actually pretty important—especially if you're into energy efficiency. Copper has been a go-to material for ages because it’s excellent at conducting electricity and heat, making it super handy in all sorts of electrical and electronic gadgets. Lately, we've seen advances showing that copper’s thermal conductivity is better than many other materials, and that’s a big deal—it helps spread out heat more effectively and cuts down on energy losses in these systems. This is pretty crucial because it helps devices run smoothly within their ideal thermal limits, so they don’t overheat or waste energy.

Plus, science is pushing the envelope even further. Researchers are working on new composites—like combining nitrogen-doped graphene with copper—that actually lower electrical resistivity and boost thermal performance. Basically, these new materials could be game-changers for future electrical contacts. Adding graphene into copper not only makes it better at conducting heat but also strengthens it mechanically. So yeah, as everyone gets more serious about saving energy, exploring these kinds of advanced materials is definitely going to shape the future of how we manage thermal and electrical performance in tech. Pretty exciting times, right?

Applications of Bare Copper Strips: Maximizing Energy Transfer in Electrical Systems

Bare copper strips are really gaining popularity in electrical setups lately, and for good reason — they’ve got awesome conductivity and can actually help cut down on energy losses. You’ll find them pretty handy in all kinds of systems, like power grids, solar panels, and energy storage units. One of the things that makes copper such a winner is its fantastic thermal and electrical properties, which means energy flows more smoothly and you end up saving on energy costs overall.

If you're using bare copper strips, here are a couple of pointers to help you get the most out of them. First off, make sure you install them properly — a tight, secure connection is key to keeping resistance low and preventing energy from slipping away. Also, keep an eye on the environment because copper can oxidize over time, which might mess with its conductivity. Regular checks and maybe a little protective coating can go a long way in keeping things running smoothly and extending the lifespan of your connectors.

And don’t forget — choosing the right size for your application is super important. The gauge and width of the strip will really impact how much current it can carry and how well it dissipates heat, which in turn affects overall efficiency. So, take the time to pick the correct strips and keep these tips in mind, and you'll see a noticeable boost in your system's performance.

Cost-Effectiveness of Bare Copper Strips in Long-Term Electrical Infrastructure

Bare copper strips are really catching on as a go-to choice for electrical setups these days, mainly because they’re cost-effective and offer long-term perks. They’re great at conducting electricity and hold up well over time, so you’ll find them useful in all kinds of projects—whether it’s wiring or grounding. If you’re thinking about how durable your electrical system will be down the line, investing in bare copper strips is a smart move. They can cut down on maintenance and help you save energy too.

Tip: When you’re picking out bare copper strips, make sure to check that they have the right industry certifications—that’s your cue for quality and dependability. Also, pay attention to the thickness; thicker strips can handle more current, which means less chance of overheating and a safer setup overall.

One more thing worth mentioning is that if they’re treated properly, these strips resist corrosion pretty well. That means you won’t have to replace them often, saving you money in the long run. Going for top-notch materials isn’t just good for your wallet but also a small way to support more sustainable and energy-efficient practices.

Tip: Keep an eye on your copper strips over time—regular inspections for wear and tear can make a big difference. Setting up a routine maintenance schedule helps your system last longer and keeps everything running smoothly without surprises. Staying proactive like this really pays off and makes your projects more cost-effective overall.

Industry Standards and Compliance for Utilizing Bare Copper Strips in Electrical Projects

Using bare copper strips in electrical work really lines up with industry standards, which are kind of like the gold standard for quality and safety. Recently, there’s been a bunch of effort to ramp up quality control for copper products — over 60 new Quality Control Orders (QCOs) have been rolled out, covering 318 product standards, including all the key specs you’d want for copper. It’s a smart move to make sure electrical wires and cables don’t just work, but also meet strict guidelines — you know, keeping everyone safe and stuff.

Plus, having BIS certification for copper products really shows how serious the industry is about safety and top-notch quality. When manufacturers make sure their products pass these safety hurdles, they’re better equipped to offer energy-efficient solutions. That’s good news for users and the environment alike. As companies pour money into new tech and smarter manufacturing methods, sticking to these standards doesn’t just boost product trustworthiness — it also lines up with bigger goals around energy efficiency. So, adopting bare copper strips while following these rules can actually lead to big improvements in how well electrical setups perform and how efficient they are overall.

Unlocking the Advantages of Bare Copper Strip in Electrical Applications for Energy Efficiency

Innovative Technologies Integrating Bare Copper Strips for Improved Electrical Performance

You know, using bare copper strips in electrical setups is actually a pretty big step forward when it comes to boosting efficiency and overall performance. These days, tech innovations are really making the most of these conductive parts to improve electrical connections and cut down on energy wastage. I mean, as industries chase better sustainability and efficiency, going with bare copper strips really helps with heat dissipation and makes the conductivity much better — which is super important for high-performance electrical systems.

Here at Sichuan D&F Electric Co., Ltd., we've been leading the charge on this kind of tech since we started back in 2005. We're based right in the middle of Deyang, and our focus is on making top-notch electrical connection components and insulation parts. Because of the unique qualities of bare copper, we can deliver products that don’t just meet the standard — they go way beyond! We're always pushing to improve what we offer, ensuring our clients get reliable, energy-efficient solutions that really make a difference in their electrical systems.

Unlocking the Advantages of Bare Copper Strip in Electrical Applications for Energy Efficiency

| Application Area | Efficiency Improvement (%) | Conductivity (IACS %) | Temperature Coefficient (µΩ·cm) | Key Advantage |

|---|---|---|---|---|

| Renewable Energy Systems | 15 | 100 | 1.68 | Enhanced Conductivity |

| Electric Vehicles | 20 | 98 | 1.72 | Weight Reduction |

| Industrial Machinery | 12 | 99 | 1.70 | Increased Durability |

| Power Distribution | 18 | 95 | 1.77 | Lower Energy Loss |

| Telecommunications | 10 | 97 | 1.69 | Signal Integrity |

Maximizing Efficiency with China High Quality Laminated Bus Bar: A Comprehensive Guide to Benefits and Applications

Laminated bus bars, also known as composite bus bars or low inductance bus bars, have gained significant traction in modern electrical applications due to their remarkable efficiency and reliability. These engineered components are crafted by stacking copper conductive layers, interspersed with thin dielectric materials, and then laminating them into a unified structure. This unique design not only enhances the electrical conduction but also minimizes inductance and improves thermal management. According to industry reports, the global market for laminated bus bars is expected to witness a robust CAGR of around 8% from 2023 to 2029, fueled by the increasing demand for efficient power distribution systems across various sectors.

The benefits of using high-quality laminated bus bars extend beyond basic electrical efficiency. Their low inductance characteristics significantly reduce the electromagnetic interference (EMI), making them ideal for sensitive electronic applications. Furthermore, laminated bus bars offer a compact design, which is especially beneficial in high-density environments such as data centers and electric vehicle powertrains. Surveys conducted by industry stakeholders indicate that the application of laminated bus bars in these fields has led to up to a 30% reduction in energy loss compared to traditional bus bar systems, demonstrating their critical role in enhancing operational efficiency.

In addition to their performance advantages, laminated bus bars also ensure superior structural integrity and durability. As industrial sectors increasingly focus on sustainability and energy efficiency, the adoption of laminated bus bars is expected to rise, aligning with global initiatives aimed at reducing carbon footprints. With their versatility and efficiency, laminated bus bars are becoming an indispensable component in modern electrical engineering and power management solutions.

FAQS

: Bare copper strips offer excellent electrical conductivity, which reduces energy loss during transmission, leading to cost savings and a lower carbon footprint. They are also durable and corrosion-resistant, minimizing the need for frequent maintenance.

Bare copper strips exhibit superior thermal conductivity compared to other materials, allowing for efficient heat dissipation and reducing energy losses, which enhances the performance of electrical devices.

Bare copper strips are ideal for various systems, including electrical grids, solar panels, and energy storage solutions, as they enhance energy transfer and efficiency.

Proper installation is essential to minimize resistance points, and regular maintenance is recommended to prevent oxidation, which can affect conductivity. Protective coatings may also help extend the life of the connections.

Matching the strip size to specific application requirements is critical; the appropriate gauge and width affect current-carrying capacity and heat dissipation, which are important for energy efficiency.

Yes, innovations such as nitrogen-doped graphene-copper composites have shown significantly lower electrical resistivity and improved thermal conductivity, enhancing the efficiency of electrical applications.

Environmental factors can lead to oxidation of bare copper, which can compromise its conductivity. Regular maintenance and protective coatings are crucial to maintaining optimal performance.

Embracing bare copper strips as part of energy-efficient practices can significantly enhance energy efficiency across a range of electrical applications, contributing to sustainability efforts.

Related Posts

-

How to Choose the Best Tin Plated Copper Bus Bar for Your Electrical Needs

-

Exploring Alternative Options to Best Gpo3 Sheets for Savvy Global Buyers

-

Global Market Insights: Projecting the Future of Best Epoxy Fiberglass Tubes by 2025

-

Exploring the Unique Properties and Applications of Best Nomex T410 Film: A Comprehensive Guide for Buyers

-

The Ultimate Checklist to Choosing the Best Copper Bus Bar for Global Procurement

-

5 Key Insights on Winding Insulation Class for Optimal Motor Performance