Top 10 Benefits of Using Rigid Aluminum Busbars in Electrical Systems

Table of Contents

- Overview of Rigid Aluminum Busbars in Electrical Systems

- Enhanced Electrical Conductivity with Rigid Aluminum Busbars

- Durability and Longevity of Aluminum Busbars in Harsh Environments

- Space-Saving Advantages of Using Rigid Aluminum Busbars

- Cost-Effectiveness of Rigid Aluminum Busbars Compared to Alternatives

- Thermal Management Benefits of Rigid Aluminum Busbars

- Safety Improvements with Rigid Aluminum Busbar Installation

- The Essential Guide to Choosing Custom Rigid Copper or Aluminum Bus Bars for Your Electrical Projects

- FAQS

- Conclusion

- Related Posts

In the fast-changing world of electrical engineering, making power distribution systems efficient and reliable is more important than ever. One thing that's really been catching people's attention lately is the Rigid Aluminum Busbar. It’s known for being tough, versatile, and pretty dependable—making it a key player in modern electrical setups. Basically, it’s a smart solution for spreading electrical power across different kinds of projects. Not only does this new tech improve how smoothly everything runs, but it also helps make our electrical infrastructure more sustainable over the long haul.

Now, when you talk about the perks of using Rigid Aluminum Busbars, it’s more than just about working well. They pack a punch in terms of durability, saving weight, and even saving money—stuff that can totally change how electrical systems are built and maintained. Whether you’re dealing with factories, office buildings, or renewable energy farms, these busbars can boost performance while cutting down on maintenance costs. As we go through the top 10 reasons why Rigid Aluminum Busbars are a game-changer, it’s good to keep in mind how they can handle rising power demands while still keeping everything safe and dependable. Basically, adopting this tech isn’t just about upgrading systems; it’s about solving real problems engineers face every day around the world.

Overview of Rigid Aluminum Busbars in Electrical Systems

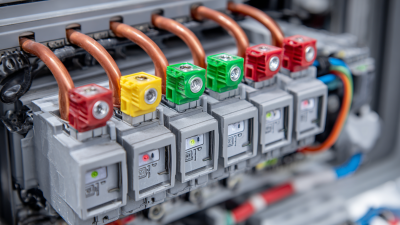

Rigid aluminum busbars are integral components in modern electrical systems, serving as primary conduits for electrical power distribution. Their robust construction allows them to handle high current loads efficiently, making them suitable for various applications, including industrial settings, commercial buildings, and renewable energy systems. According to a report by the International Energy Agency (IEA), the rising demand for efficient power management solutions has spurred significant advancements in busbar technology, with aluminum emerging as a preferred material due to its favorable conductivity-to-weight ratio.

The advantages of rigid aluminum busbars extend beyond weight efficiency; they also provide excellent thermal management and resistance to corrosion. A study by the Electric Power Research Institute (EPRI) highlights that aluminum’s thermal conductivity effectively dissipates heat generated during operation, which enhances the overall lifespan of electrical systems. Furthermore, their high resistance to oxidation ensures performance longevity in both indoor and outdoor environments, making them a reliable choice for engineers designing complex electrical architectures. This versatility and reliability are critical as industries increasingly shift towards sustainable practices and technologies in the energy sector.

Enhanced Electrical Conductivity with Rigid Aluminum Busbars

Rigid aluminum busbars are increasingly favored in electrical systems due to their enhanced electrical conductivity. Unlike traditional copper alternatives, aluminum busbars provide a lightweight yet robust solution, minimizing the overall weight of electrical assemblies while still delivering impeccable performance. The unique properties of aluminum allow for efficient current distribution, effectively reducing energy losses and improving the overall efficiency of electrical systems.

When using rigid aluminum busbars, it is essential to ensure proper installation to maximize their conductivity. **Tip:** Always check for clean and smooth connections, as any dirt or oxidation on the surface can hinder performance. Additionally, consider the cross-sectional area of the busbars; larger areas will further decrease resistance and enhance conductivity.

Moreover, the ability of aluminum to dissipate heat effectively contributes to its reliability in electrical applications. **Tip:** Ensure that the busbars are adequately sized for the load requirements to avoid overheating. Proper thermal management not only extends the life of the electrical system but also enhances safety by minimizing the risk of failures due to overheating. Adopting rigid aluminum busbars is a forward-thinking choice that aligns with the energy efficiency goals of modern electrical systems.

Top 10 Benefits of Using Rigid Aluminum Busbars in Electrical Systems

Durability and Longevity of Aluminum Busbars in Harsh Environments

Rigid aluminum busbars are increasingly recognized for their exceptional durability and longevity, particularly in harsh environments where traditional electrical conductors may falter. The inherent properties of aluminum, including its resistance to corrosion, make it an ideal choice for applications subjected to extreme temperatures, moisture, and aggressive chemicals. Unlike copper, aluminum offers a lightweight alternative that does not sacrifice strength, ensuring that even under severe working conditions, the busbars maintain their structural integrity and functionality.

Furthermore, the longevity of aluminum busbars translates to significant cost savings over time. In environments prone to high levels of vibration or thermal cycling, the robust nature of aluminum minimizes the risk of failure and the associated downtime. The insulation and protective coatings applied to these busbars further enhance their resilience, allowing them to withstand industrial stresses that can degrade other materials. By choosing rigid aluminum busbars, industries can ensure consistent performance and reliability, fostering a safer and more efficient electrical system.

Space-Saving Advantages of Using Rigid Aluminum Busbars

Rigid aluminum busbars offer significant space-saving advantages in electrical systems, making them an ideal choice for modern infrastructure. Unlike traditional wiring methods, which may require extensive cabling and junction boxes, rigid busbars streamline electrical connections. Their compact and robust design allows for high current carrying capabilities without the bulk associated with larger cable systems, optimizing both space and weight in electrical installations. This is especially beneficial in environments where every square inch counts, such as in data centers, industrial settings, and commercial buildings.

Moreover, the arrangement of rigid aluminum busbars permits greater flexibility in system design. Their modular nature enables engineers to configure electrical systems more efficiently, reducing the need for extensive cable runs and facilitating easier access for maintenance and upgrades. By minimizing the physical footprint of electrical components, rigid aluminum busbars can lead to improved airflow, enhanced cooling efficiency, and overall system reliability. This innovative approach to electrical distribution not only conserves space but also supports the trend towards more compact and efficient designs in contemporary electrical engineering.

Cost-Effectiveness of Rigid Aluminum Busbars Compared to Alternatives

Rigid aluminum busbars are gaining popularity in electrical systems due to their significant cost-effectiveness compared to alternative solutions like copper busbars. According to a recent industry report, aluminum busbars can be around 30-40% cheaper than copper variants when considering both material costs and installation expenses. This considerable price difference is attributed to the lower density of aluminum, which allows for lighter and easier handling, reducing labor costs during installation. Additionally, the durability and resistance to corrosion of aluminum can lead to lower maintenance costs over time, making it an attractive long-term investment for businesses.

Moreover, the efficiency of rigid aluminum busbars in terms of conductivity is noteworthy. Although copper has a higher conductivity, aluminum busbars are engineered to optimize performance, resulting in minimal power loss. The U.S. Department of Energy reports that utilizing more efficient busbar systems can yield an overall energy savings of 5-10%, further enhancing the economic feasibility for large-scale operations.

**Tips:** When selecting busbar materials, always consider not just the initial costs but also the long-term savings on energy and maintenance. It's advisable to consult with industry professionals to assess the specific needs of your electrical system. Additionally, ensure compliance with local regulations for safety and efficiency standards when opting for rigid aluminum busbars.

Top 10 Benefits of Using Rigid Aluminum Busbars in Electrical Systems

| Benefit | Description | Cost-Effectiveness |

|---|---|---|

| High Electrical Conductivity | Rigid aluminum busbars provide excellent conductivity, which minimizes energy loss. | Lower operational costs due to reduced energy waste. |

| Lightweight | Easier to handle and install compared to other metal busbars. | Reduced labor costs due to easier installation. |

| Versatility | Suitable for various electrical applications, from low to high voltage. | Cost savings by being applicable in multiple scenarios. |

| Durability | Resistant to corrosion and environmental factors. | Lower replacement costs due to long lifespan. |

| Space Efficiency | Compact design allows for space-saving configurations. | Less room needed for installations, reducing facility costs. |

| Heat Dissipation | Effective at dissipating heat during operation. | Lower cooling costs and increased system reliability. |

| Lower Electrical Losses | Minimizes losses compared to other busbar materials. | Results in significant savings over time. |

| Reduced Maintenance Needs | Less prone to damage and wear. | Savings from less frequent service requirements. |

| Customizability | Can be manufactured to precise specifications. | Eliminates the need for costly modifications. |

| Sustainability | Recyclable material with a lower carbon footprint. | Long-term savings aligned with environmental goals. |

Thermal Management Benefits of Rigid Aluminum Busbars

Rigid aluminum busbars offer significant thermal management advantages in electrical systems, making them a preferred choice for many applications. Due to their high thermal conductivity, rigid aluminum busbars effectively dissipate heat generated during electrical conduction. This property not only prevents overheating but also contributes to the overall efficiency of the system, ensuring that components remain within their optimal operating temperatures. This is particularly important in high-load environments where excessive heat can lead to equipment failure or reduced lifespan.

Moreover, the lightweight nature of aluminum facilitates easier installation and integration into various systems, enhancing thermal performance. In addition, the large surface area of rigid busbars allows for better airflow, promoting natural cooling. With an effective thermal management strategy, these busbars can maintain stable temperatures even under heavy loads, reducing the need for additional cooling solutions.

This not only lowers the overall energy consumption of the electrical system but also minimizes maintenance costs associated with overheating issues. The benefits of using rigid aluminum busbars extend beyond just electrical efficiency, highlighting their crucial role in promoting a sustainable and reliable electrical infrastructure.

Safety Improvements with Rigid Aluminum Busbar Installation

The installation of rigid aluminum busbars in electrical systems significantly enhances safety protocols in various applications. One of the primary benefits is their ability to conduct power efficiently while minimizing overheating. Rigid aluminum busbars are designed to handle high current loads, which mitigates the risk of thermal runaway and electrical fires that can occur with less organized wiring solutions. By distributing electrical load evenly, they reduce the hot spots that commonly lead to system failures.

Moreover, the robust construction of rigid aluminum busbars contributes to improved insulation and protection against environmental factors. Unlike traditional wires, which can be susceptible to abrasion and wear, busbars are often coated or housed in protective casings that prevent unintended contact and electrical arcing. This added layer of safety not only safeguards the equipment but also the personnel working around these systems. Additionally, the clearly defined pathways of busbars simplify maintenance and inspections, allowing for easier identification of potential hazards before they escalate into serious incidents.

The Essential Guide to Choosing Custom Rigid Copper or Aluminum Bus Bars for Your Electrical Projects

When selecting custom rigid copper or aluminum bus bars for electrical projects, several critical factors must be considered to ensure optimal performance and safety. Rigid bus bars, which can be CNC machined from high-quality copper or aluminum materials, serve as essential components for conveying current and establishing connections within electrical circuits. According to industry reports, the global busbar market was valued at approximately USD 2.7 billion in 2021, with expectations to grow significantly due to increasing demand for efficient power distribution systems.

One main advantage of copper bus bars over aluminum is their superior conductivity and lower resistive losses. Researchers have determined that copper's electrical conductivity is approximately 60% higher than that of aluminum, making it the preferred choice in applications where minimizing energy loss is crucial. Moreover, choosing rounded or chamfered designs for bus bars can mitigate the risks associated with point discharge, enhancing overall safety and performance.

Additionally, the versatility of bus bars is worth noting. They can be custom fabricated according to specific technical requirements, allowing for tailored solutions that meet unique project demands. As the trend towards renewable energy and advanced electrical infrastructures continues to rise, the importance of selecting the right bus bars becomes increasingly evident. High-quality manufacturing processes, such as CNC machining, ensure that the bus bars produced are reliable and meet stringent industry standards, ultimately supporting the growing landscape of electrical systems.

FAQS

: Rigid aluminum busbars are components used for electrical power distribution, designed to handle high current loads efficiently in various applications like industrial settings and renewable energy systems.

Rigid aluminum busbars provide excellent thermal management due to aluminum’s high thermal conductivity, which dissipates heat effectively during operation, enhancing the lifespan of electrical systems.

Rigid aluminum busbars are more space-efficient than traditional wiring methods, allowing high current capacities without the bulk of larger cabling systems, especially beneficial in confined environments like data centers.

The modular nature of rigid aluminum busbars allows for more flexible system designs, reducing the need for extensive cable runs and facilitating easier maintenance and upgrades.

Rigid aluminum busbars can be 30-40% cheaper than copper alternatives, thanks to lower material and installation costs, while their durability can lead to reduced maintenance expenses over time.

Although aluminum has lower conductivity than copper, optimized aluminum busbars can result in minimal power loss, potentially yielding energy savings of 5-10% for large-scale operations.

Aluminum’s high resistance to corrosion ensures long-term performance in various environments, making it a reliable choice for maintaining the integrity of electrical systems.

When selecting busbar materials, it's essential to consider initial costs alongside long-term savings on energy and maintenance, and to consult with professionals to ensure compliance with local regulations.

Rigid aluminum busbars are especially advantageous in environments where space is limited, such as data centers, industrial settings, and commercial buildings, due to their compact design.

By minimizing physical footprint and optimizing airflow, rigid aluminum busbars can lead to improved cooling efficiency and enhance the overall reliability of electrical systems.

Conclusion

Rigid Aluminum Busbars are becoming increasingly popular in electrical systems due to their multiple advantages. One of the primary benefits is enhanced electrical conductivity, which allows for efficient power distribution. These busbars also offer remarkable durability and longevity, making them ideal for harsh environments where traditional materials may fail. Their compact design leads to significant space-saving advantages, making installations cleaner and more efficient.

Furthermore, Rigid Aluminum Busbars are cost-effective compared to alternative solutions, providing a great return on investment. In addition to their economic benefits, they contribute to effective thermal management, helping to maintain optimal operating temperatures. Finally, the installation of Rigid Aluminum Busbars can enhance safety by reducing fire risks and improving overall system reliability. Overall, these factors underscore the growing preference for Rigid Aluminum Busbars in modern electrical infrastructure.

Related Posts

-

Understanding the Advantages of Rigid Aluminum Busbar in Modern Electrical Systems

-

What is Rigid Aluminum Busbar and Its Applications in Electrical Systems

-

How to Choose the Best Electrical Insulating Board for Your Project

-

How to Choose the Right Metal Bus Bar for Your Electrical Needs

-

Ultimate Guide to Choosing the Right Flexible Busbar Connectors for Your Systems

-

Understanding the Efficiency of Composite Busbars in Modern Electrical Systems