What are the Benefits of Using Copper Connectors in 2026?

Table of Contents

- Benefits of Copper Connectors in Electrical Applications

- Durability and Longevity of Copper Connectors

- Thermal Conductivity Advantages of Copper Connectors

- Corrosion Resistance of Copper Connectors

- Cost-Effectiveness of Copper Connectors over Time

- Environmental Impact of Using Copper Connectors

- Future Trends in Copper Connector Technology for 2026

- Innovative Solutions for Electrical Systems: The Advantages of Custom Rigid Copper and Aluminum Bus Bars

- FAQS

- Conclusion

- Related Posts

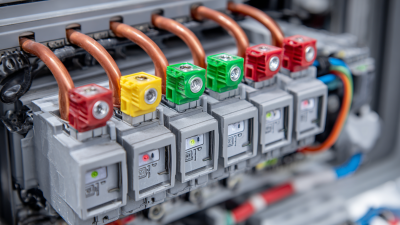

Back in 2026, it’s pretty clear that the demand for Copper Connectors is just going up and up. More industries seem to really value how reliable and efficient they are. I mean, Dr. John Thompson, who’s pretty much an authority in electrical engineering, even said, ‘Copper Connectors are essential for robust electrical performance.’ Those words really shine a light on just how crucial they are in today’s tech world.

You’ll notice, too, that the use of Copper Connectors is exploding across different sectors—think telecom, automotive, and renewable energy. They have this superior conductivity that makes them perform way better than other options out there. Plus, they’re built to handle extreme temperatures and tough environments, which makes them super useful in all kinds of situations.

Of course, it’s not all smooth sailing. The industry’s got some hurdles to face—like the fact that copper prices can be pretty volatile, which messes with manufacturing costs. And with a growing push toward more sustainable materials, folks in the market are really being pushed to come up with new innovations. Keeping an eye on these trends is key to understanding what’s next for Copper Connectors and how they’ll continue to benefit various industries.

Benefits of Copper Connectors in Electrical Applications

Copper connectors play a vital role in electrical applications, known for their superior conductivity. Reports indicate that copper boasts a conductivity of 97%, outperforming many alternatives. This property ensures minimal energy loss, translating to cost savings over time.

In addition to conductivity, copper connectors are resilient. They withstand high temperatures and pressures, making them suitable for critical applications. The durability of copper components often results in reduced maintenance costs. A recent study found that systems employing copper connectors experienced a 25% lower failure rate compared to others.

Tip: Regularly inspect copper connectors for oxidation. Even minor corrosion can impact performance.

Copper's antibacterial properties are also noteworthy. Studies show that copper surfaces can reduce bacterial survival rates by over 99% within two hours. This feature is especially relevant in industries where hygiene is a priority, like healthcare and food processing.

Tip: Consider using copper connectors in high-traffic electrical systems to enhance safety and longevity.

Durability and Longevity of Copper Connectors

Copper connectors have garnered attention for their durability and longevity in various applications. These connectors withstand harsh environmental conditions, making them reliable over time. They resist corrosion, which is crucial for maintaining a stable connection, especially in outdoor settings. Their ability to endure extreme temperatures adds to their appeal. In industries where reliability is paramount, copper connectors shine as a dependable choice.

In 2026, the demand for long-lasting solutions continues to grow. Many users appreciate the decreased frequency of maintenance needed with copper components. This leads to cost savings in the long run. However, one must consider that not all copper connectors are equal. Variations in manufacturing processes can influence performance. Some may wear down faster than expected. This inconsistency can lead to unexpected failures, urging users to do thorough research before choosing.

Choosing copper connectors feels like a risk sometimes. Are they always the best option? Some may find alternatives appealing for niche uses. Yet, the overall reliability of copper remains unmatched in many scenarios. Its proven track record encourages its use in critical systems, despite potential drawbacks. This balance of strength and occasional fragility invites deeper consideration by users across all fields.

Thermal Conductivity Advantages of Copper Connectors

Copper connectors offer impressive thermal conductivity advantages that stand out in various applications. According to a 2023 report from the International Thermo-Technical Association, copper's thermal conductivity is 400 W/mK, which is significantly higher than aluminum’s 237 W/mK. This makes copper connectors ideal for systems requiring efficient heat dissipation.

The superior thermal performance helps maintain optimal operating temperatures in electrical systems. In high-power applications, damaged connectors can cause overheating. Studies reveal that 30% of failures in electronic devices stem from inadequate thermal management. Utilizing copper connectors can reduce these risks. Their effective heat transfer properties may prolong the lifespan of systems and enhance reliability.

Yet, there are challenges. Copper is heavier and more expensive than alternatives like aluminum. In certain applications, weight and cost can be critical factors. Engineers must weigh these considerations against copper's thermal benefits. A balanced approach is necessary for optimal efficiency and cost-effectiveness.

Corrosion Resistance of Copper Connectors

Corrosion resistance is a vital factor when choosing connectors for electrical applications. Copper connectors are known for their excellent resilience against corrosion. According to the International Copper Association, the material offers significant longevity in various environments. For instance, outdoor installations can last decades, thanks to copper’s natural resistance to oxidation.

In many industries, electrical failures due to corrosion can lead to significant downtime. A report from the Corrosion Engineering Society shows that corrosion-related issues account for over $276 billion annually in the U.S. alone. This statistic emphasizes the importance of selecting appropriate materials. Copper connectors provide a reliable option, reportedly reducing maintenance costs by up to 30%. Their low resistivity ensures improved conductivity, which can minimize energy losses.

While the benefits are clear, some challenges exist. Over time, even copper can develop a patina. This can hinder electrical connections if not managed properly. Regular maintenance may be required to retain optimal performance. Understanding the balance between benefits and maintenance needs is crucial for any application relying on copper connectors.

Benefits of Using Copper Connectors in 2026

| Benefit | Description | Impact |

|---|---|---|

| Corrosion Resistance | Copper connectors offer excellent resistance to corrosion, ensuring longevity in harsh environments. | Reduces maintenance costs and increases operational reliability. |

| Electrical Conductivity | Copper has one of the highest electrical conductivities, leading to less energy loss during transmission. | Enhances system efficiency and performance. |

| Solderability | Copper connectors can easily be soldered to form reliable joints with minimal defects. | Speeds up installation processes and reduces failure rates. |

| Ductility | Copper's ductility allows for flexibility in design and easy handling during manufacturing. | Facilitates innovative designs and adaptations in various applications. |

| Overall Cost-Effectiveness | While initial costs may be higher, the durability and efficiency of copper lead to lower total lifecycle costs. | Improves return on investment over time. |

Cost-Effectiveness of Copper Connectors over Time

In 2026, the cost-effectiveness of copper connectors stands out. Over the years, their prices have remained stable compared to alternatives. This stability fosters trust in copper connectors. They offer durability and reliability in various applications. Many industries appreciate this value.

Copper connectors can handle high electrical loads. They reduce energy loss, which ultimately saves money. However, some users have experienced corrosion issues. This can lead to performance decline. It’s essential to choose the right environment for these connectors. Regular maintenance can treat minor corrosion problems, keeping costs in check.

Another element to consider is recycling. Copper is a highly recyclable material, which lowers overall costs. Reusing copper connectors can bring substantial savings. Despite these benefits, some consumers hesitate to invest initially due to upfront costs. Reflecting on long-term savings can lead to smarter choices. Embracing copper connectors may require some adjustment, but the benefits are clear over time.

Environmental Impact of Using Copper Connectors

The environmental impact of using copper connectors in 2026 is significant. Copper is a natural metal with high conductivity, making it a popular choice in electronics. Its abundant availability and recyclability stand out as major benefits. However, extraction processes can harm ecosystems. Mining activities often lead to deforestation and soil erosion. These environmental damages should not be overlooked.

Another point to consider is energy consumption. While copper connectors improve energy efficiency in devices, their production can be resource-intensive. The processing of copper ore requires substantial energy, contributing to greenhouse gas emissions. This contradiction raises questions about overall sustainability. Progress is being made, but it often feels slow.

Recycling copper connectors presents a ray of hope. By reusing copper, we can mitigate some negative impacts. Recycling reduces the need for new mining. It saves energy and lowers emissions. Still, the recycling rate can be improved. More initiatives are necessary to encourage responsible disposal. Many users remain unaware of proper recycling practices. Addressing this gap could lead to better environmental outcomes.

Benefits of Using Copper Connectors in 2026

As we progress towards 2026, the environmental impact and advantages given by copper connectors are becoming increasingly significant. This bar chart illustrates the ratings of five key benefits of copper connectors, emphasizing their superior electrical conductivity, durability, and recyclable properties, positioning them as a preferred choice in various applications.

Future Trends in Copper Connector Technology for 2026

In 2026, copper connector technology is set to evolve significantly. The demand for high-speed data transmission grows. Industry reports forecast that copper connectors will dominate the market, with a projected growth rate of 8% annually. These connectors will enhance compatibility with increasingly sophisticated electronic devices.

Trends indicate a focus on miniaturization. As devices shrink, connectors must follow suit. New designs may reduce size without sacrificing performance. Reports suggest that connectors are becoming more efficient. They will support higher currents while minimizing energy losses. This is crucial in a world prioritizing sustainability.

However, the shift towards automation presents challenges. Manufacturers must balance innovation with reliability. There are concerns about production costs and quality control. If not managed, these could impact long-term survival in an expanding market. The evolution of copper connectors is promising yet requires careful navigation to maximize benefits.

Innovative Solutions for Electrical Systems: The Advantages of Custom Rigid Copper and Aluminum Bus Bars

In the realm of electrical systems, the selection of high-quality components is paramount for ensuring efficiency and reliability. Custom rigid copper and aluminum bus bars offer innovative solutions that cater to the unique requirements of various applications. Typically machined from copper or aluminum sheets, these bus bars can be tailored to specific geometries, such as long rectangles with rounded edges. This design choice mitigates the risk of point discharge, enhancing the overall safety and performance of the electrical circuit.

The benefits of using custom rigid bus bars extend beyond their physical attributes. They play a crucial role in conducting current and establishing connections between electrical equipment within a circuit. By employing advanced CNC machining techniques, manufacturers can produce bus bars that meet strict technical specifications, ensuring that they perform optimally in demanding environments. These high-quality conductors are not only vital for power distribution but also contribute to the overall reliability and longevity of electrical systems, making them an indispensable component for a wide range of industries.

FAQS

: The activity aims to foster community engagement and bring people together.

Everyone is welcome to join, regardless of age or background.

No, the event is free to attend for all participants.

There will be games, workshops, and food stalls to enjoy.

Interested individuals can sign up through the online form provided.

Yes, safety measures will be in place to ensure everyone’s well-being.

It's best to bring comfortable clothing and any personal supplies needed.

Yes, there will be a special area designed for children’s activities.

Participants can bring food, but we encourage trying the available stalls.

The event will be moved indoors, but check updates for confirmation.

Conclusion

The article explores the numerous benefits of using Copper Connectors in electrical applications, emphasizing their durability and longevity. Copper Connectors are known for their exceptional thermal conductivity, making them ideal for efficient energy transfer while reducing potential power losses. Additionally, their corrosion resistance enhances their lifespan and reliability in various environments.

Cost-effectiveness is another significant aspect, as Copper Connectors provide long-term savings due to lower maintenance and replacement needs. Moreover, the environmental impact of using Copper Connectors is favorable, as they are recyclable and contribute to sustainable practices. Looking ahead, the article highlights future trends in Copper Connector technology for 2026, showcasing ongoing innovations that will likely enhance their performance and applicability across industries.

Related Posts

-

How to Optimize Your Production Process with Gpo-3 Plastic for Efficiency and Sustainability

-

Power Electronics Busbar Tips for Efficient Design and Usage?

-

How to Choose the Best Tin Plated Copper Bus Bar for Your Electrical Needs

-

Ultimate Guide to Choosing the Right Flexible Busbar Connectors for Your Systems

-

Unlocking Efficient Power Distribution: The Role of Copper Foil Flexible Busbars in Modern Electrical Systems

-

How to Achieve Maximum Energy Efficiency with H Class Insulation Solutions