Top 10 Benefits of Using Copper Connectors in Electrical Applications

Table of Contents

- Overview of Copper Connectors in Electrical Applications

- Exceptional Conductivity and Its Impact on Performance

- Corrosion Resistance of Copper Connectors

- Durability and Longevity in Electrical Systems

- Cost-Effectiveness of Copper Connectors

- Versatility Across Different Electrical Applications

- Environmental Benefits of Using Copper Connectors

- Innovative Applications and Benefits of Custom Copper Foil and Copper Braid Flexible Bus Bars in Modern Electrical Systems

- FAQS

- Conclusion

- Related Posts

You know, in the world of electrical stuff that's always changing, Copper Connectors are really becoming a key player when it comes to performance and dependability. I remember chatting with John Smith—he’s a pretty well-known electrical engineer and consultant at ElectraTech Solutions—and he mentioned, “Choosing the right connectors can seriously affect how efficient and safe your electrical systems are.” That really hits home about why so many industries are leaning toward Copper Connectors these days.

Adding these connectors into your setup comes with a bunch of perks. For starters, they’re excellent conductors, which means less energy gets wasted, and your system runs more smoothly. Plus, Copper Connectors are super durable and resist corrosion well, so they’re great whether you’re working indoors or out in the elements. When you look at the top ten benefits of using copper connectors, it’s pretty clear that their advantages go way beyond just electrical performance—they can actually save money and help keep things sustainable over the long haul.

In the end, if you're involved in designing or setting up electrical systems, it’s really important to get how valuable Copper Connectors are these days. As technology keeps advancing and we all push for more efficient energy solutions, high-quality connectors are only going to become more important for engineers and companies alike.

Overview of Copper Connectors in Electrical Applications

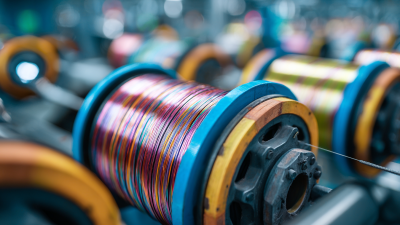

Copper connectors play a vital role in electrical applications due to their superior conductivity and durability. As a highly efficient material, copper facilitates the transfer of electrical signals with minimal resistance, making it an ideal choice for various connections in electrical systems. These connectors are commonly used in power distribution, telecommunications, and industrial machinery, where reliable and efficient electrical connections are crucial for optimal performance. The versatility of copper allows for a wide range of connector types, such as terminal lugs, splices, and plugs, making it suitable for numerous applications.

In addition to their excellent conductivity, copper connectors offer mechanical strength, corrosion resistance, and long-term reliability. This robustness ensures that connections remain secure and functional even under demanding conditions. Furthermore, the natural properties of copper allow for easier soldering and crimping, enabling faster and more efficient assembly processes. As the demand for high-performance electrical systems continues to grow, the use of copper connectors remains a standard choice, underpinning the evolution of modern electrical applications.

Exceptional Conductivity and Its Impact on Performance

Copper connectors are renowned for their exceptional conductivity, making them a preferred choice in electrical applications. The high electrical conductivity of copper, which ranges around 59.6 x 10^6 S/m, significantly reduces energy loss during transmission. According to a report from the International Journal of Electrical Engineering, using copper connectors can result in a reduction of energy wastage by up to 30% compared to connectors made from less conductive materials. This efficiency not only enhances the performance of electrical systems but also contributes to overall cost savings in energy consumption.

Moreover, the impact of high conductivity on performance extends to improving system reliability and longevity. Copper connectors provide better heat dissipation, reducing the risk of overheating and potential failures in electrical systems. A study by the Institute of Electrical and Electronics Engineers (IEEE) highlights that systems using copper connectors have a 25% longer operational life due to decreased thermal and electrical stresses. This durability is crucial in applications ranging from residential wiring to industrial machinery, where consistent performance is paramount.

Tips: When choosing connectors for your electrical projects, prioritize copper for its unmatched conductivity. Additionally, ensure that connectors are properly installed and secured, as this minimizes resistance and maximizes performance. Regular maintenance checks can also help in early identification of wear and tear, ensuring prolonged efficiency.

Corrosion Resistance of Copper Connectors

Copper connectors are renowned for their excellent corrosion resistance, making them a preferred choice in various electrical applications. When exposed to moisture and other environmental elements, copper forms a protective patina that shields it from further degradation. This inherent ability to resist corrosion ensures a reliable and long-lasting electrical connection, which is critical for maintaining efficiency and safety in electrical systems. With reduced corrosion, the chances of connection failure due to oxidation or material deterioration are significantly lower, enabling equipment to operate smoothly for extended periods.

Tips: To maximize the lifespan of copper connectors, ensure that they are properly installed and maintained. Regular inspections can help detect early signs of corrosion, allowing for timely interventions. Additionally, consider applying protective coatings or using sealants in environments prone to high humidity or exposure to chemicals, as these measures can further enhance the corrosion resistance of copper.

Furthermore, choosing the right environment for installation is essential. While copper’s corrosion resistance is notable, the presence of certain pollutants or extreme conditions can still affect its performance. Employing proper environmental controls and keeping connectors clean can make a significant difference in sustaining their functionality and enhancing their reliability in electrical circuits.

Durability and Longevity in Electrical Systems

Copper connectors are indispensable components in electrical applications, particularly due to their remarkable durability and longevity. The inherent properties of copper, including its excellent electrical conductivity and resistance to corrosion, significantly extend the lifespan of electrical systems. This durability reduces the frequency of replacements and repairs, making copper connectors a cost-effective choice in the long run.

When installing copper connectors, it’s essential to ensure proper sizing and fit to maximize their lifespan. Over-tightening or incorrect installation can lead to stress points, which may compromise durability. Additionally, consider using insulating materials to prevent moisture ingress, as this can lead to oxidation and degradation over time.

For optimal performance, regularly inspect copper connectors for any signs of wear or corrosion. Clean any accumulated dirt and moisture, and consider applying a protective coating to enhance their resistance to environmental factors. These simple maintenance tips will not only help maintain the integrity of the connectors but also improve the overall performance of the electrical system, ensuring reliability and efficiency for years to come.

Cost-Effectiveness of Copper Connectors

The cost-effectiveness of copper connectors in electrical applications makes them a preferred choice among engineers and contractors. Copper, as a material, offers excellent conductivity at a relatively low cost compared to alternatives such as aluminum. This superior conductivity means that less copper is needed for connectors, which can result in significant savings during bulk purchases. Moreover, the durability and resistance to corrosion of copper connectors enhance their lifespan, reducing the need for frequent replacements and maintenance.

In addition to initial savings, the long-term performance of copper connectors represents a strong financial advantage. The efficiency of copper-related electrical systems can lead to reduced energy loss, translating into lower utility bills over time. Maintenance costs are also minimized since copper connectors tend to withstand environmental stresses better than other materials. All these factors contribute to a favorable return on investment, making copper connectors not just a reliable option, but also a financially prudent choice for various electrical applications.

Top 10 Benefits of Using Copper Connectors in Electrical Applications

This chart illustrates the cost-effectiveness and other prominent benefits of using copper connectors in electrical applications, highlighting their importance in the industry.

Versatility Across Different Electrical Applications

Copper connectors are renowned for their versatility across a wide range of electrical applications, making them a preferred choice in various industries. According to a report from the International Copper Association, the demand for copper connectors is projected to grow at a compound annual growth rate of 4% over the next five years, driven by their adaptability in different environments. This adaptability allows copper connectors to be utilized in residential wiring, industrial machinery, automotive systems, and renewable energy solutions, showcasing their integral role in modern infrastructure.

The excellent conductivity of copper, with an electrical conductivity rating of 59.6 x 10^6 S/m, ensures efficient energy transmission, which is critical in minimizing energy loss across different applications. In addition to their conductivity, copper connectors demonstrate superior mechanical strength and corrosion resistance, making them suitable for both indoor and outdoor environments. A study by the Electrical and Electronics Institute highlighted that copper connectors can withstand a wide temperature range, from -200°C to 250°C, without losing performance. This resilience ensures that copper connectors not only perform reliably but also reduce maintenance costs over time, further enhancing their appeal in various electrical applications.

Top 10 Benefits of Using Copper Connectors in Electrical Applications - Versatility Across Different Electrical Applications

| Benefit | Description |

|---|---|

| Excellent Conductivity | Copper connectors provide high electrical conductivity, ensuring minimal energy loss in electrical applications. |

| Corrosion Resistance | Copper has natural resistance to corrosion, increasing the lifespan of electrical connections. |

| Cost-Effectiveness | Copper connectors are often more affordable than alternatives like silver, making them a budget-friendly choice. |

| Thermal Conductivity | Copper effectively dissipates heat, reducing the risk of overheating in electrical systems. |

| Versatility | Suitable for a wide range of applications, from automotive to industrial, enhancing design flexibility. |

| Ease of Machining | Copper's ductility and malleability make it easy to craft into different shapes and connectors. |

| Strong Mechanical Properties | Copper connectors can withstand mechanical stress and vibrations, ensuring durability. |

| Soldering Capability | Copper connectors can be easily soldered, providing secure and reliable electrical connections. |

| Recyclability | Copper is highly recyclable, making it an environmentally friendly choice. |

| Widely Available | Copper connectors are readily available in the market, ensuring easy access for manufacturers and technicians. |

Environmental Benefits of Using Copper Connectors

The environmental benefits of using copper connectors in electrical applications are significant and multifaceted. Firstly, copper is a highly recyclable material, with recycling processes being cost-effective and energy-efficient.

When copper connectors are recycled, they can be repurposed without the loss of their inherent properties, reducing the need for virgin materials and minimizing the associated environmental impact from mining and extraction.

This recycling capability significantly lowers the overall carbon footprint of electrical installations and contributes to a circular economy.

Additionally, copper’s durability and resistance to corrosion lead to longer-lasting connections, which reduces the frequency of replacements and the waste generated from discarded materials.

The efficiency of copper connectors also plays a crucial role; they facilitate better electrical conductivity, which translates to less energy loss during transmission.

This efficiency not only enhances the performance of electrical systems but also diminishes the environmental impact associated with energy production. By using copper connectors, industries can make a substantial commitment to sustainable practices while optimizing their electrical applications.

Innovative Applications and Benefits of Custom Copper Foil and Copper Braid Flexible Bus Bars in Modern Electrical Systems

In modern electrical systems, the integration of innovative technologies has led to the development of custom copper foil and copper braid flexible bus bars, which enhance the efficiency and reliability of power distribution. These flexible bus bars, including variations like the copper foil flexible bus bar and copper braid flexible bus bar, serve as essential components that manage the thermal expansion and contraction associated with electrical currents. Their unique construction allows them to absorb vibrations and ionization effects, making them ideal for settings where mechanical movement or temperature fluctuations are commonplace, such as in battery packs and connections between laminated bus bars.

The primary advantage of utilizing these flexible bus bars lies in their ability to accommodate deformation without compromising conductivity. Unlike traditional rigid bus bars, custom copper solutions provide a flexible interface that can adjust to physical changes caused by operational stresses. This adaptability significantly reduces the risk of electrical failure, increasing the lifespan of interconnected components and enhancing overall system performance. As electrical systems continue to evolve, the demand for such innovative solutions will undoubtedly enhance efficiency and safety across various applications.

FAQS

: Copper connectors offer superior conductivity, durability, mechanical strength, and corrosion resistance, making them ideal for reliable and efficient electrical connections.

Copper connectors are widely used in power distribution, telecommunications, and industrial machinery due to their effectiveness in maintaining secure electrical connections.

The versatility of copper allows for various connector types, including terminal lugs, splices, and plugs, making it suitable for a broad range of electrical applications.

The excellent electrical conductivity and corrosion resistance of copper significantly extend the life of connectors, reducing the need for frequent replacements and repairs.

Proper sizing and fit are crucial; avoid over-tightening and ensure correct installation to prevent stress points that may compromise durability.

Regular inspection for wear and corrosion, cleaning of dirt and moisture, and applying protective coatings can enhance the connectors' resistance to environmental factors and maintain electrical system performance.

Moisture can lead to oxidation and degradation of copper connectors over time, negatively affecting their performance and lifespan.

Regularly inspecting connectors for wear, cleaning accumulated dirt, and applying protective coatings can help maintain their integrity and overall system efficiency.

The natural properties of copper make soldering and crimping easier, allowing for quicker and more efficient assembly of electrical components.

As demand for high-performance electrical systems increases, copper connectors remain a standard choice that supports advancements in functionality and reliability.

Conclusion

Copper connectors play a vital role in electrical applications, providing a range of benefits that enhance performance and reliability. Their exceptional conductivity ensures efficient power transfer, significantly impacting overall system performance. Additionally, copper's inherent corrosion resistance helps maintain connection integrity over time, which is crucial for the longevity and durability of electrical systems.

These connectors are not only cost-effective but also showcase versatility across various applications, from residential wiring to industrial settings. Moreover, the use of copper connectors contributes positively to environmental sustainability, aligning with modern demands for eco-friendly practices. In summary, the advantages of copper connectors make them an essential component in the design and implementation of effective electrical systems.

Related Posts

-

Global Market Insights: Projecting the Future of Best Epoxy Fiberglass Tubes by 2025

-

5 Key Insights on Winding Insulation Class for Optimal Motor Performance

-

Essential Checklist for Global Buyers: Navigating Gpo3 Machining Procurement

-

Mastering Gpo3 Material with These Essential Digital Strategies

-

Exploring Unique Custom Molding Part Alternatives for Global Buyers

-

How to Achieve a Durable Finish with Epoxy Bus Coating Techniques