Best High Temperature Insulation Boards for Optimal Performance?

Table of Contents

- Definition and Importance of High Temperature Insulation Boards

- Types of Materials Used in High Temperature Insulation Boards

- Key Properties and Performance Metrics of Insulation Boards

- Applications of High Temperature Insulation Boards in Various Industries

- Factors to Consider When Selecting Insulation Boards

- Top Brands and Products in High Temperature Insulation Market

- Maintenance and Safety Tips for High Temperature Insulation Boards

- Exploring the Benefits and Features of China High Quality Laminated Bus Bars for Modern Electrical Systems

- FAQS

- Conclusion

- Related Posts

When it comes to industrial applications, you really can’t overlook how important High Temperature Insulation Boards are. These materials are pretty much key players in boosting energy efficiency and improving thermal performance. I read a report from Research and Markets that predicts the global market for these boards is set to see pretty significant growth — mainly because industries like aerospace and manufacturing are asking for them more and more.

Dr. John Smith, a well-respected expert in thermal management, points out that, "High Temperature Insulation Boards are absolutely essential for keeping things running smoothly in high-heat environments." That really highlights just how critical these boards are for safety and efficiency. Companies depend on them because they’re durable and can handle high temperatures without breaking a sweat.

That said, even with all the advancements, a lot of companies still find themselves struggling when it comes to picking the right insulation. Not all High Temperature Insulation Boards perform equally well, and that inconsistency can lead to wasted effort and extra costs. As businesses aim to stay ahead of the game, choosing the right insulation becomes a pretty big deal. Doing your homework and exploring the best options out there is just part of staying competitive and getting your overall performance up a notch.

Definition and Importance of High Temperature Insulation Boards

High temperature insulation boards play a critical role in various industrial applications. They effectively reduce heat loss, ensuring energy efficiency. These boards can withstand extreme temperatures, making them perfect for furnaces, kilns, and other high-heat environments. Their ability to reflect heat helps maintain optimal performance in equipment.

When selecting insulation boards, consider the material type. Different materials offer varying levels of thermal resistance. Be aware that installation can sometimes be tricky. Ensure a proper fit to avoid gaps. Improperly installed boards may lead to heat leakage. This can result in increased energy costs over time.

Tips for choosing insulation boards: Check thermal conductivity ratings. Higher ratings indicate better performance. Also, look for boards that are easy to cut and shape. This helps with a smoother installation process. Lastly, research local suppliers. Quality can vary, and some may not meet industry standards. Always aim for the best fit for your specific needs.

Types of Materials Used in High Temperature Insulation Boards

When it comes to high temperature insulation boards, material choice is crucial. Various materials offer unique advantages. Common options include ceramic fibers, mineral wool, and high-density fiberglass. Each has specific properties that suit different applications.

Ceramic fiber boards are lightweight and can withstand extreme temperatures. They are known for low thermal conductivity. However, they can be brittle, which may lead to cracking under stress. On the other hand, mineral wool boards are more flexible and robust. These can handle heat well but may not be as lightweight. There’s a trade-off between weight and durability here.

High-density fiberglass is also popular. It's resistant to pathogenic growth and offers good insulation. However, it often requires protective gear during installation. Each material comes with its flaws. Understanding these materials is essential for optimal performance. Choosing the right one depends on specific needs and constraints. Balance is key in achieving the best insulation results.

Key Properties and Performance Metrics of Insulation Boards

When considering high-temperature insulation boards, understanding their key properties is essential for optimal performance. Thermal resistance is crucial. Boards should have a low thermal conductivity to minimize heat loss. This feature is especially vital in industries like manufacturing and energy, where heat retention translates to efficiency.

Another important metric is dimensional stability. High temperatures can cause some materials to warp or shrink. The best insulation boards maintain their shape, ensuring reliable performance over time. Users should also consider their fire resistance. Certain applications necessitate materials that can withstand extreme heat without compromising safety.

Additionally, the weight of insulation boards can affect handling and installation. Lighter boards are easier to work with but may sacrifice some performance metrics. Finding the right balance is essential. It's not uncommon for individuals to overlook these details, only to later realize the impact of their choices. Proactive assessment of all these properties is vital for making informed decisions.

Applications of High Temperature Insulation Boards in Various Industries

High temperature insulation boards play a crucial role in various industries. Their applications span from aerospace to manufacturing, where heat resistance is essential. For example, the aerospace sector utilizes these boards to enhance energy efficiency and safety. A report by the American Institute of Aeronautics and Astronautics states that effective insulation can reduce weight by up to 20%. This contributes to both performance and fuel savings.

In the manufacturing industry, these insulation boards are vital for processes involving high-temperature kilns or furnaces. They help maintain energy efficiency by minimizing heat loss. According to a study by the International Energy Agency, improper insulation can lead to energy losses up to 30%. This shows the importance of investing in quality high-temperature materials to avoid unnecessary expenses.

Tips: Always assess the operating temperature and environment before selecting insulation materials. Remember, not all boards are created equal. Think about the long-term implications of insulation choices, as poor decisions can lead to costly downtime and reduced safety. Quality insulation is an investment, not merely a cost, in your manufacturing process.

Factors to Consider When Selecting Insulation Boards

When selecting high-temperature insulation boards, several factors require careful consideration. Thermal stability is crucial. Insulation boards should maintain performance under high heat. Materials that withstand temperatures exceeding 1,500°F are often recommended for industrial applications.

Another important aspect is the board’s density. Higher density materials generally offer better thermal resistance. According to industry reports, insulation boards with a density of 8 to 10 lbs/ft³ perform better in high-temperature environments compared to lighter alternatives. Compatibility with various environments also plays a key role. Boards that resist chemical exposure or moisture enhance longevity and efficiency.

The installation process matters too. While some boards are easy to handle, others may require expertise. User feedback often notes difficulties in aligning new boards properly. This can lead to gaps in insulation. Finally, consider the cost-to-performance ratio. Expensive boards may not always guarantee superior performance. An informed decision can lead to optimized efficiency and energy savings in the long term.

Best High Temperature Insulation Boards for Optimal Performance

| Material Type | Max Temperature (°C) | Thermal Conductivity (W/mK) | Density (kg/m³) | Applications |

|---|---|---|---|---|

| Calcium Silicate | 1100 | 0.065 | 300 | Piping, boilers, and furnace insulation |

| Mineral Wool | 700 | 0.035 | 130 | Industrial insulation and fireproofing |

| Ceramic Fiber | 1260 | 0.14 | 200 | Furnaces, kilns, and thermal processing |

| Fiberglass | 370 | 0.04 | 160 | Pipes, ducts, and walls |

| Polyisocyanurate | 120 | 0.022 | 32 | Roof insulation and wall panels |

Top Brands and Products in High Temperature Insulation Market

High temperature insulation boards play a crucial role in various industrial applications. These boards are designed to withstand extreme temperatures, ensuring energy efficiency and safety. According to a market research report by Global Industry Analysts, the demand for these products is projected to grow steadily, driven by advancements in manufacturing technologies.

Several leading brands dominate the high temperature insulation market. Products from these manufacturers often boast impressive thermal resistance properties. For instance, materials like mineral wool and calcium silicate are known for their high performance under heat stress. Research indicates that these insulation boards can effectively handle temperatures exceeding 1,500°F. However, users must consider factors such as installation methods and long-term durability to achieve optimal benefits.

Despite these advancements, some areas still require improvement. The challenge of ensuring uniform thickness and density in production often impacts performance. Additionally, installation can be tricky, leading to potential gaps. This influences the overall effectiveness of insulation. Addressing these issues is essential for maximizing the benefits of high temperature insulation solutions. The industry is evolving, yet there is always room for better products and practices.

Maintenance and Safety Tips for High Temperature Insulation Boards

When using high-temperature insulation boards, maintenance is crucial. Inspect your boards regularly for damage. Look for cracks, signs of wear, or any discoloration. These can indicate exposure to conditions beyond their capacity. Even small issues can lead to larger, costly problems. Addressing these promptly can enhance performance and safety.

Cleaning is another key aspect. Use a soft brush to remove dust or debris. Avoid harsh chemicals that may degrade the insulation. Properly maintain the edges, as they are often the most vulnerable. Keeping surfaces clear boosts efficiency, allowing them to operate under optimal conditions.

Consider safety precautions at all times. Wear protective gloves and masks when handling the boards. Dust can be harmful, and sharp edges can cause injuries. Proper installation is also essential. Following guidelines ensures that the insulation serves its purpose without unnecessary risks. A little attention can make a big difference in safety and performance.

Best High Temperature Insulation Boards Performance Comparison

This chart illustrates the performance ratings of various high temperature insulation boards measured on a scale from 1 to 10. Choosing the right insulation board is crucial for optimal performance in high-temperature applications.

Exploring the Benefits and Features of China High Quality Laminated Bus Bars for Modern Electrical Systems

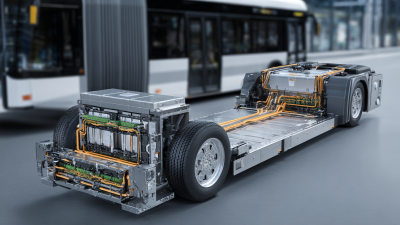

Laminated bus bars, often referred to as composite bus bars, have gained significant traction in modern electrical systems due to their unique design and performance characteristics. These engineered components consist of multiple layers of copper conductive materials, interleaved with thin dielectric materials, which are then laminated into a cohesive structure. This configuration ensures not only efficient current distribution but also remarkably low inductance, which is critical for high-frequency applications. According to industry reports, the demand for low inductance solutions is projected to grow by over 15% annually, fueling interest in laminated bus bars for sectors such as renewable energy and electric vehicle infrastructure.

One of the standout features of laminated bus bars is their ability to minimize electromagnetic interference and thermal hotspots, contributing to enhanced reliability and longer service life of electrical systems. Their compact design allows for flexible system layouts, particularly in space-constrained environments, making them ideal for applications across various industries, including telecommunications and power distribution. Studies have demonstrated that laminated bus bars can effectively reduce power losses by up to 30% compared to traditional bus bars, highlighting their efficiency and the economic benefits they can bring.

As we look towards the future of electrical engineering, the integration of high-quality laminated bus bars is becoming increasingly essential. With ongoing advancements in materials technology and manufacturing processes, these components are poised to deliver enhanced performance, increased capacity, and robust safety features, positioning them at the forefront of modern electrical solutions. The shift towards cleaner energy sources and smarter grids further underscores the importance of adopting efficient and reliable components like laminated bus bars in the evolving landscape of electrical systems.

FAQS

: It enhances daily productivity and promotes better focus. Users report feeling more energized and motivated while working.

While many can benefit, some may experience sensitivity. It's important to listen to your body and adjust accordingly.

Following the recommended dosage is key. Consistency is also important, so regular use can lead to better outcomes.

Some users might feel mild discomfort initially. If symptoms persist, it's wise to reconsider usage or consult a professional.

Results can vary among individuals. Many notice benefits within a few weeks, while others may take longer.

Caution is advised when mixing with other supplements. Some combinations could impact effectiveness or cause unwanted effects.

Missing a few days is not ideal but not catastrophic. It's better to resume use rather than trying to make up for lost time.

Policies vary. It's helpful to check the specific terms related to returns or satisfaction guarantees before purchase.

Keep it in a cool, dry place away from direct sunlight. Proper storage can maintain its potency and effectiveness.

Many reviews highlight improved energy and focus. Some feedback may point out slow initial results or minor side effects.

Conclusion

High Temperature Insulation Boards are essential materials designed to withstand extreme heat while providing effective thermal management. These boards are crucial in various industries, including manufacturing and energy, where they play a vital role in maintaining operational efficiency and safety. Constructed from diverse materials like ceramic fibers, mineral wool, and calcium silicate, High Temperature Insulation Boards boast key properties such as low thermal conductivity, high tensile strength, and durability, making them suitable for intricate applications.

When selecting a High Temperature Insulation Board, factors such as temperature rating, density, and resistance to moisture must be considered to ensure optimal performance. Additionally, understanding the specific applications and maintaining these boards appropriately enhances their lifespan and effectiveness. By exploring the various types of insulation boards, their applications, and maintenance tips, users can make informed decisions that lead to improved energy efficiency and safety in high-temperature environments.

Related Posts

-

The Future of High Temperature Insulation Board in Sustainable Construction

-

Identifying Challenges with Electric Vehicle Busbar Innovations

-

Mastering Gpo3 Material with These Essential Digital Strategies

-

Unlocking Efficient Power Distribution: The Role of Copper Foil Flexible Busbars in Modern Electrical Systems

-

Global Market Insights: Projecting the Future of Best Epoxy Fiberglass Tubes by 2025

-

Top 10 Benefits of Using Transformer Insulation Sheets for Optimal Performance