What Constitutes Busbar Insulator Material in Electrical Systems

Table of Contents

- Types of Busbar Insulator Materials in Electrical Systems

- Key Properties Required for Effective Busbar Insulators

- Commonly Used Materials in Busbar Insulator Manufacturing

- Environmental Considerations in Busbar Insulator Selection

- Performance Comparison of Different Busbar Insulation Types

- Innovative Insulation Solutions: The Benefits of Epoxy Fiberglass Cloth Insulation Tubes in Modern Applications

- FAQS

- Conclusion

- Related Posts

Making sure electrical systems run smoothly and safely really comes down to choosing the right materials, especially when it comes to parts like busbar insulators. If you’ve read any industry reports, you’ll notice how critical these insulators are—they’re the key to both electrical insulation and mechanical stability, especially for high-voltage setups.

I came across a report from Market Research Future that predicts the global market for busbar insulation is gonna see some pretty strong growth, mostly because of the rising need for dependable power supply in busy cities and industrial areas. And speaking of the industry, Sichuan D&F Electric Co., Ltd., which has been around since 2005, is definitely a name to keep in mind.

They’re really leaders in providing top-notch electrical connection parts and insulation components. For those of us in manufacturing and electrical work, understanding how different busbar insulator materials work and where they’re best used is pretty much essential if we want to keep our systems reliable and efficient in today’s modern infrastructure.

Types of Busbar Insulator Materials in Electrical Systems

Busbar insulator materials are super important when it comes to keeping electrical systems running safely and smoothly. Basically, they’re designed to provide both electrical insulation and sturdy support for busbars, which are key players in distributing power. There are a few different types of these insulator materials, each with their own perks for different situations. For example, epoxy resin is pretty popular because it offers great electrical insulation and can handle high temps without breaking a sweat. Ceramic insulators are also widely used thanks to their toughness and ability to resist environmental wear and tear.

Then there’s silicone rubber—lots of folks love it for its flexibility and awesome weather resistance, especially for outdoor setups. And don’t forget about polymer-based insulators—they’re becoming more popular because they’re lightweight, pack a high dielectric strength, and do a good job fighting off pollution. As a trusted manufacturer and supplier, Sichuan D&F Electric Co., Ltd. is committed to providing top-quality electrical components and insulation parts. We really want our customers to get the best materials, tailored to whatever their busbar projects need. Basically, we’re all about making sure you have reliable, high-quality options for your electrical setups.

Key Properties Required for Effective Busbar Insulators

Busbar insulators are pretty important when it comes to electrical setups. They basically support and separate

the busbars from other parts of the system, all while keeping things safe and efficient. To do their job well, these insulators need to have a few key features. First off,

they should have high dielectric strength—that’s a fancy way of saying they can handle a lot of electrical stress

without breaking down. This is crucial because it helps prevent short circuits and keeps the whole system running smoothly.

Another thing to keep in mind is thermal stability. Good busbar insulators can handle a wide range of temperatures

without falling apart. So, using materials that resist heat really helps them last longer and stay reliable, even when the environment isn’t so friendly. Plus,

mechanical strength Matters — they need to survive bumps, vibrations, or even impacts during operation.

Pro tip: When you're picking out insulator materials, go for ones that resist chemicals

and the elements. If the setup is outdoors, insulators with strong weatherproofing and UV resistance are a game changer—it really extends their lifespan. And don’t

forget to check the manufacturer’s specs to make sure they’re a good fit for your specific electrical system. Trust me, a little extra due diligence here can save

you a lot of trouble down the line.

Commonly Used Materials in Busbar Insulator Manufacturing

You know, busbar insulators really are a key part of keeping electrical systems running smoothly and safely. Picking the right materials for them isn’t just a minor detail — it seriously impacts how well they perform and how long they last. Usually, you’ll find ceramics, glass, and a bunch of polymer-based composites in use.

Ceramics, for example, are awesome because they have great dielectric properties and can handle pretty high temperatures, so they’re often the go-to for high-voltage stuff. Plus, they’re tough enough to handle rough outdoor conditions.

Then there’s glass insulators. They’re pretty sturdy and durable, and they do a good job insulating electricity. The coolest part? They’re transparent, which actually makes it super easy to check for damage or dirt without taking them apart — definitely a plus when it comes to maintenance.

And lately, polymer composites are really catching on. They’re lightweight and resistant to the elements—weather, moisture, you name it. Plus, engineers can customize these materials to boost thermal and electrical performance, making them super versatile for all sorts of modern electrical needs. Overall, choosing the right material isn’t just about ticking boxes — it’s the key to making sure the system stays reliable and works efficiently for the long haul.

Environmental Considerations in Busbar Insulator Selection

When you're choosing materials for busbar insulators in electrical systems, it's super important to think about the environment they'll be in. Things like big temperature swings, humidity, or exposure to dirt and pollutants can really affect how well insulation works and how long it lasts. For example, if you're installing something outdoors, you'll want materials that can handle UV rays and rough weather — nobody wants their insulators cracking under the sun or in a storm. Also, if they're in industrial settings, being resistant to chemicals and corrosive stuff is a big plus.

Here's a little tip: Before picking your insulator, take a good look at the site’s conditions. Knowing exactly what the environment throws at it helps you pick a material that won’t give up easily.

Lately, there's been a big push towards using more sustainable materials for these insulators. Manufacturers are now looking into eco-friendly options that don't harm the planet during production or disposal. Choosing recyclable or biodegradable insulators isn’t just good for the environment — it also helps build a more sustainable power infrastructure.

Another tip: Check if the insulator materials come with eco-labels or environmental certifications. That way, you can be more confident they’re not only good for the planet but also tough enough to handle the conditions they’re exposed to.

Performance Comparison of Different Busbar Insulation Types

Busbar insulators really are a key piece of the puzzle in electrical systems. They help keep everything running smoothly and safely by stopping unwanted electrical sparks or discharges and making sure everything performs as it should. When it comes to the materials used for insulation in busbars, there’s quite a variety — like epoxy resin, polyurethane, and silicone rubber — and each one has its own perks. Industry folks say that epoxy resin insulators are pretty impressive because they handle high temperatures—up to 150°C—without losing their electrical reliability and also offer good mechanical strength. On the flip side, silicone rubber insulators get a lot of praise for handling the great outdoors—they’re resistant to UV rays, moisture, and other environmental challenges, which makes them perfect for outdoor projects.

When you're comparing different insulators, it’s important to look at stuff like how strong they are electrically (dielectric strength), how tough they are physically (durability), and how well they transfer heat (thermal conductivity). Recent research shows that polyurethane insulators can handle dielectric strengths over 20 kV/mm, making them a pretty solid choice for high-voltage use. Oh, and by the way, Sichuan D&F Electric Co., Ltd. has been around since 2005, mainly focusing on making top-notch electrical connection parts and insulation materials. They really push the envelope by using cutting-edge tech and materials to make sure their busbar insulators meet international standards and, even better, keep up with what today’s electrical systems need.

Innovative Insulation Solutions: The Benefits of Epoxy Fiberglass Cloth Insulation Tubes in Modern Applications

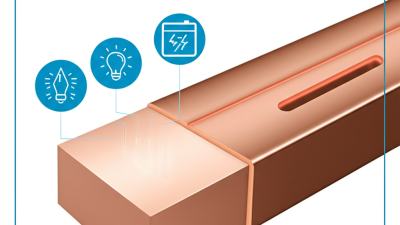

Epoxy fiberglass cloth insulation tubes have emerged as a reliable solution for modern industrial applications, offering distinct advantages in electrical insulation and thermal management. Constructed from alkali-free glass fabric bonded with epoxy resin, these tubes are laminated under high temperature pressure, ensuring enhanced durability and stability. A recent industry report highlighted that materials like G10 and G11 are not only bestsellers in the insulation market but also account for a significant share in sectors requiring high-performance insulation solutions, particularly in electronics and manufacturing.

The versatility of epoxy fiberglass insulation tubes extends beyond their primary electrical insulating properties. The twine technology used in their production allows for varied dimensions, supporting a wide range of applications, from high-voltage electrical equipment to automotive components. According to data from the Electrical Insulation Research Institute, the demand for epoxy-based materials is projected to grow at a rate of 5% annually, driven by advancements in industries that prioritize safety and efficiency. Coupled with our offerings of epoxy glass cloth laminated rods in different diameters and lengths, these insulation solutions cater to diverse market needs, reinforcing their importance in today’s technological landscape.

FAQS

: Busbar insulators serve to support and separate busbars from surrounding structures while ensuring safety and efficiency in electrical systems.

Busbar insulators should have high dielectric strength, thermal stability, and mechanical strength to withstand electrical stresses, temperature variations, and physical impacts.

High dielectric strength prevents breakdown under significant electrical stresses, which helps avoid short circuits and maintain overall system integrity.

Commonly used materials include ceramics, glass, and various polymer composites.

Ceramics offer excellent dielectric properties and thermal resistance, making them suitable for high-voltage applications and harsh environmental conditions.

Glass insulators provide high mechanical strength, are durable, and their transparency allows for easy visual inspections, enhancing maintenance.

Polymer composites are lightweight and exhibit superior resistance to environmental stressors, making them versatile for modern electrical applications.

Consideration should be given to chemical resistance, installation environment, weatherproofing, UV resistance, and compatibility with specific electrical systems.

Thermal stability allows busbar insulators to operate efficiently across a wide range of temperatures without degrading, ensuring reliability in varying conditions.

Conclusion

When it comes to electrical systems, the material used for busbar insulators really makes a difference in how reliable and efficient everything runs. This article dives into the different types of busbar insulator materials out there, spotlighting the key qualities you really want to look for—like how well they handle electricity, their heat stability, and how tough they are physically. It’s also got a rundown of the common materials used in manufacturing, pointing out what’s great about each one and where they might fall short.

On top of that, it touches on how environmental factors come into play when choosing the right insulator. It’s pretty important to think about sustainability these days, after all. Plus, there’s a handy comparison of different insulation types—showing how they perform under various conditions, which is super useful for engineers and manufacturers trying to make smart decisions.

By the way, Sichuan D&F Electric Co., Ltd. brings over ten years of experience to the table as a trusted supplier of top-notch busbar insulator materials. They’re really keeping up with the rising demands in the electrical industry, so they’re definitely a name worth knowing.

Related Posts

-

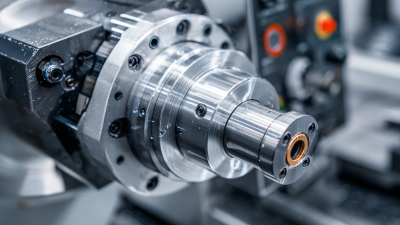

7 Essential Tips for Mastering Electrical Insulator Machining Efficiency

-

Global Market Insights: Projecting the Future of Best Epoxy Fiberglass Tubes by 2025

-

Unlocking the Advantages of Bare Copper Strip in Electrical Applications for Energy Efficiency

-

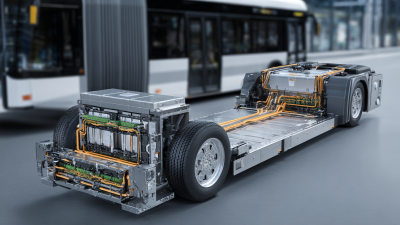

Identifying Challenges with Electric Vehicle Busbar Innovations

-

Exploring Innovations in Laminates For Class F at the 138th China Import and Export Fair 2025

-

The Ultimate Checklist to Choosing the Best Copper Bus Bar for Global Procurement