Identifying Challenges with Electric Vehicle Busbar Innovations

Table of Contents

- Challenges in Electric Vehicle Busbar Innovations: A Deep Dive

- Current Market Trends in Electric Vehicle Infrastructure and Busbars

- Technical Limitations of Existing Busbar Designs for EV Vehicles

- Impact of Material Selection on Busbar Efficiency and Performance

- Regulatory Implications for Busbar Innovations in the EV Sector

- Future Opportunities in Busbar Technology for Sustainable Transport Solutions

- Maximizing Safety and Efficiency: The Benefits of EPGC Molded Electrical Insulation Profiles in Modern Applications

- FAQS

- Conclusion

- Related Posts

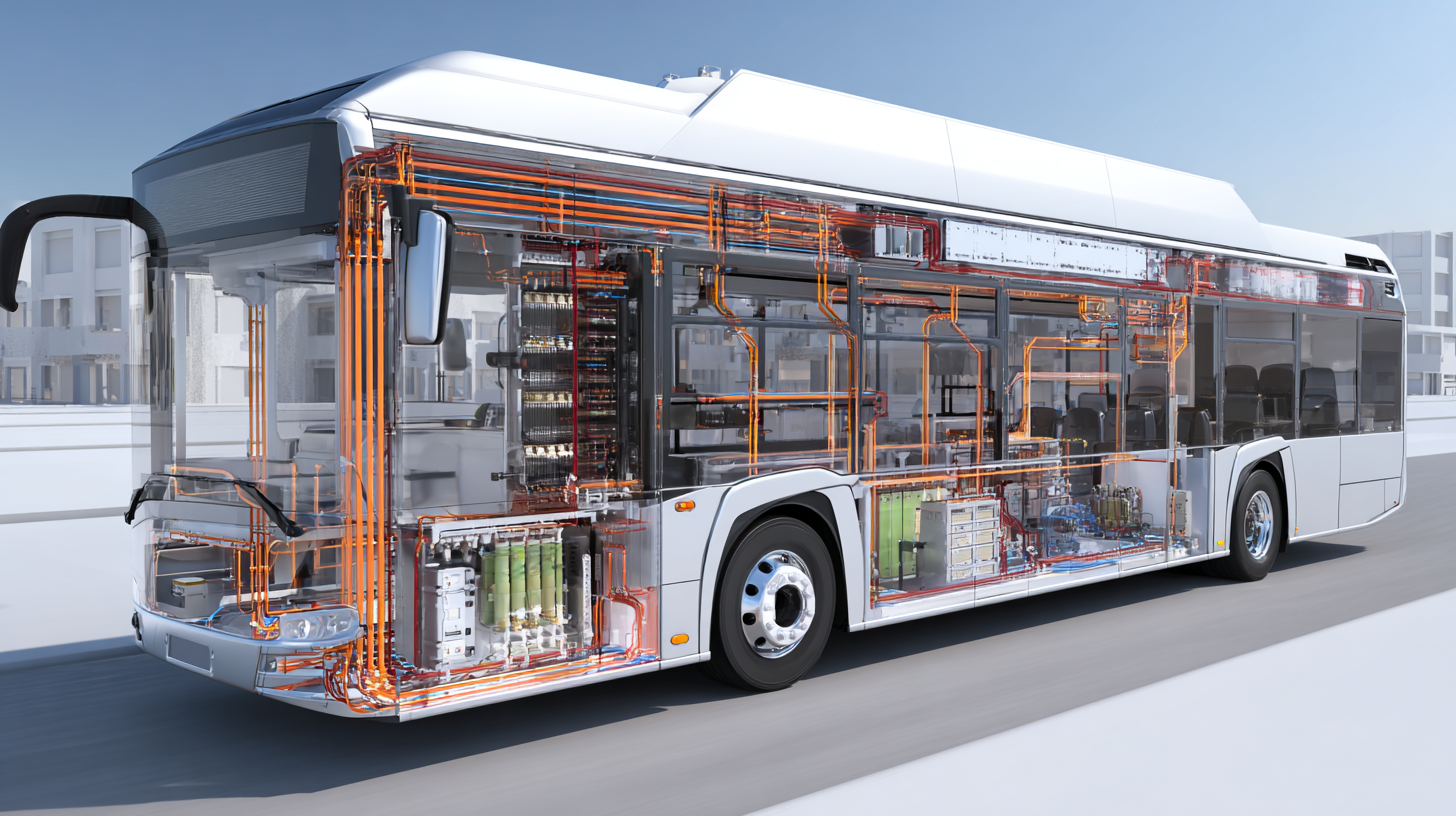

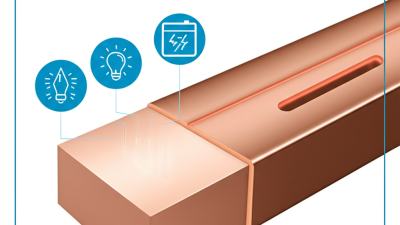

Lately, the electric vehicle world has been buzzing with new innovations—especially when it comes to the technology behind EV busbars. If you've ever looked under the hood (or rather, inside the battery systems), you’ll know that busbars are pretty much essential for making sure the electrical flow is smooth and reliable. They’re a small but mighty part that really impacts how well an EV performs and how long it lasts. Of course, with all these quick advances, there are some pretty tricky challenges that manufacturers and suppliers need to tackle—things like safety, efficiency, and making sure these parts last over time. That’s where Sichuan D&F Electric comes in. Founded back in 2005, this company is all about developing top-notch electrical connection components and insulation parts. Based in the Jinshan Industrial Park of Deyang, Sichuan, they’re constantly pushing the boundaries to improve EV busbars, helping to grow the market and make electric vehicles more sustainable for everyone.

Challenges in Electric Vehicle Busbar Innovations: A Deep Dive

You know, with how fast electric vehicle tech is moving, it's honestly pretty exciting to see all the new ideas popping up around busbar designs. But, of course, there are still some hurdles to clear. Things like managing heat, making sure everything runs efficiently, and scaling up production are all tricky parts of the equation. As EVs are becoming more and more common, having reliable busbar systems is more important than ever. Still, getting everything just right—balancing performance, safety, and durability under different conditions—isn't exactly a walk in the park.

On top of that, as folks from the electrification and automation worlds get together in workshops and seminars, it’s clear that working together is the key. These sessions led by experts are super valuable—they share the latest tech insights and best practices that can help tackle those pesky challenges in busbar design. When industry pros come together to exchange ideas, it really helps push the industry forward toward more efficient, sustainable, and dependable EV systems, which we all want to see given how fast the market is growing. The push for innovation shouldn’t just focus on flashy new tech; it’s equally about figuring out and solving the challenges that come with this rapid transition.

All in all, it’s an exciting time, but also one that needs collaboration and a bit of patience to truly make the most of these advancements.

Current Market Trends in Electric Vehicle Infrastructure and Busbars

The electric vehicle (EV) scene is really shifting gears right now, especially when it comes to charging infrastructure and busbars. Just last year, the International Energy Agency (IEA) released a report showing that there are now over 10 million EVs on the road worldwide — pretty impressive, huh? It just shows how much more people are looking for reliable charging options these days.

Busbars, those handy components that help distribute power efficiently, are playing a bigger role than ever in support of expanding charging networks. As demand for super-fast charging picks up, the market for new and improved busbar tech is expected to grow at around 11% annually through 2026. That’s a clear sign that innovation in this area is more important than ever.

If you’re in the industry, a good tip is to go for modular designs—they make it much easier to scale up charging stations as needed. Also, investing in better materials can really help with thermal management, which is crucial when stations are running at full throttle. Plus, it pays to get familiar with regional rules and regulations—this can smooth out the whole deployment process, saving you time and money. As the EV world keeps evolving, making the most of data insights will be key to staying ahead of the game and tackling any challenges that pop up along the way.

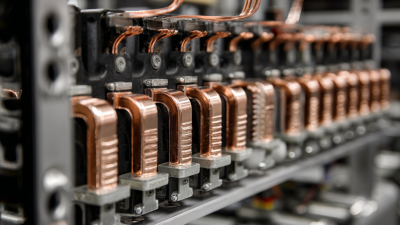

Technical Limitations of Existing Busbar Designs for EV Vehicles

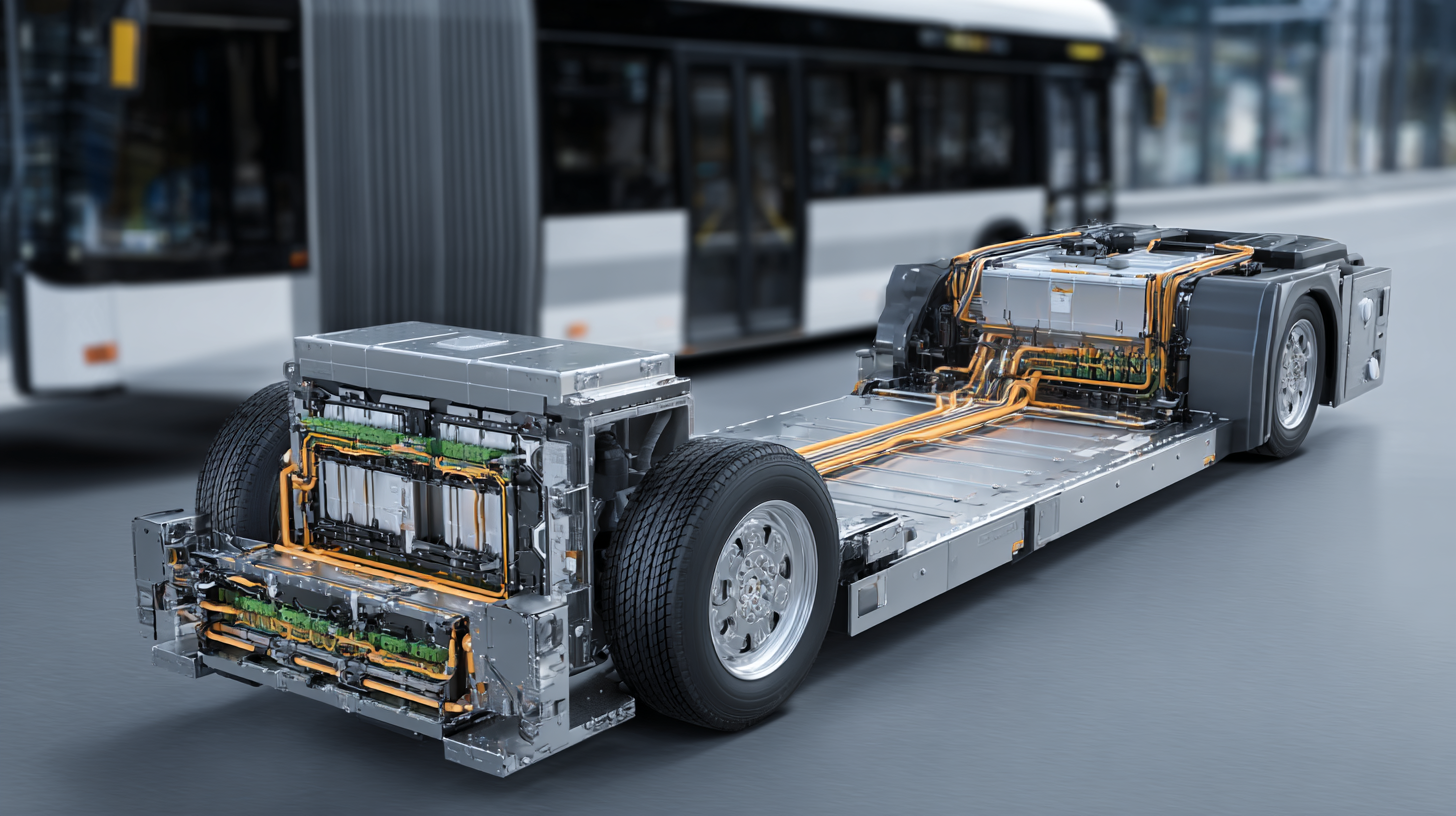

The rapidly changing world of electric vehicles (EVs) is really opening up a ton of opportunities for innovation, especially when it comes to busbar technology. But, honestly, the current designs aren’t quite cutting it. There are a few technical hurdles that are holding back the performance and efficiency of EVs. Take thermal management, for example — traditional materials just don’t cut it when it comes to dissipating all that heat during high-current use. Overheating can become a real issue, which isn’t great for reliability. That’s why diving into new materials, like advanced composites, is such a big deal — they can help improve heat dissipation and keep everything running smoothly, even under extreme conditions.

Then there’s the mechanical side of things. A lot of existing busbar designs aren’t tough enough to handle the regular vibrations and shocks that come with being on the road. Over time, that can lead to failures—definitely not ideal, especially for public buses where folks rely on them to run smoothly and safely. The trick is coming up with busbars that are lighter but also stronger, so they can withstand the beating while still boosting overall vehicle efficiency. As more people push for sustainable transport options, it’s pretty clear that tackling these technical challenges is key if we want electric buses to really take off in city environments.

Identifying Challenges with Electric Vehicle Busbar Innovations - Technical Limitations of Existing Busbar Designs for EV Vehicles

| Challenge | Description | Impact on Performance | Possible Solutions |

|---|---|---|---|

| High Thermal Resistance | Existing busbar materials often do not dissipate heat effectively. | Reduced efficiency and increased risk of overheating. | Utilizing advanced materials with better thermal conductivity. |

| Weight Limitations | Heavy busbars add significant weight to EVs, affecting range. | Compromised driving range and acceleration. | Adopting lightweight composite materials. |

| Manufacturing Costs | High costs associated with producing high-quality busbars. | Limited adoption of advanced designs due to expense. | Investing in scalable manufacturing processes. |

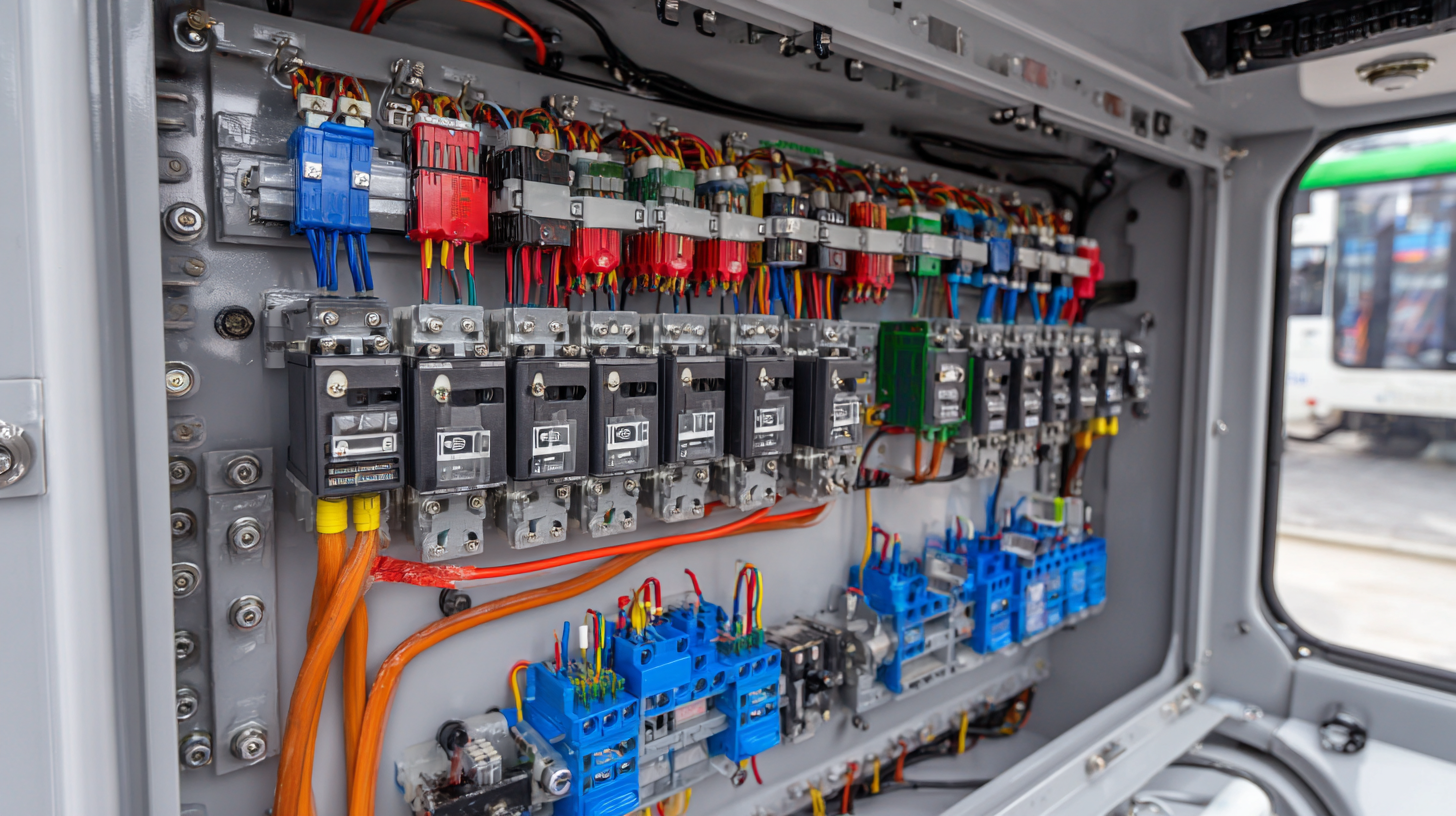

| Electromagnetic Interference | Busbars can emit unwanted electromagnetic signals. | Impact on surrounding electronic components. | Implementing shielding and improved routing techniques. |

| Corrosion Resistance | Lack of effective protection against corrosion in various environments. | Degradation of performance and lifespan. | Using corrosion-resistant coatings and materials. |

Impact of Material Selection on Busbar Efficiency and Performance

When it comes to electric vehicles, the materials used in their busbar systems really matter for their overall performance and efficiency. Busbars are key parts of the electrical setup—they need to smoothly carry power while staying strong and durable. Recently, there’s been a lot of talk about exploring new materials that can strike a good balance between conductivity, weight, and toughness. For example, swapping out traditional materials for advanced composites or better metals could actually boost how well the vehicle performs, making it more efficient overall.

But it’s not just about the materials themselves—environmental factors play a big role too. Just like solar panels need to be sturdy and well-made to perform well, busbars face stresses that might mess with their function. Heat, humidity, and physical wear and tear can cause problems like corrosion or decreased ability to carry electricity. That’s why choosing tough materials and smart design practices is so important. It can really help extend how long busbars last and keep electric vehicles reliable down the road.

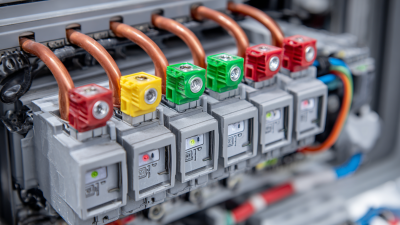

Regulatory Implications for Busbar Innovations in the EV Sector

The push for new electric vehicle (EV) busbar tech is pretty exciting—it could really boost efficiency and performance in the EV world. But, here’s the thing: regulations play a huge role in how quickly these innovations can catch on. Regulatory agencies need to put out guidelines that not only keep things safe and reliable but also leave room for manufacturers to experiment and push boundaries. As companies try out new materials and designs to get better results, sticking too tightly to existing standards can sometimes slow things down. Finding that sweet spot between solid regulation and enough wiggle room for innovation is really the key.

And it’s not just about meeting technical specs—regulations also have a big say when it comes to the environment. Policymakers are getting more serious about sustainability, which means there’s a growing push for rules that encourage eco-friendly materials. The tricky part is making sure these greener options still meet the high standards for performance and durability. That puts pressure on manufacturers—they’re trying to balance what the law demands with what consumers want.

At the end of the day, it’s all about collaboration. Working together—industry players and regulators—will be crucial to tackle these challenges and really move the needle on EV busbar tech. It’s a team effort, but the results could be pretty incredible if everyone’s on the same page.

Challenges in Electric Vehicle Busbar Innovations

Future Opportunities in Busbar Technology for Sustainable Transport Solutions

As the world shifts more and more towards sustainable transportation options,

busbar technology is really becoming a key player in advancing electric vehicle systems.

You know, with all these innovations in how busbars are designed, not only do they boost efficiency, but they also make

the electrical connections between different parts of the system work much smoother. Companies like

Sichuan D&F Electric Co., Ltd. are really pushing the envelope, focusing on creating high-quality connection components that tackle the unique challenges of EV infrastructure.

Looking ahead, the potential for busbar tech is pretty exciting—especially when it comes to better

energy distribution and cutting down on weight in electric cars.

By putting a spotlight on electrical insulation and making sure everything stays solid structurally, brands like D&F are gearing up to meet

the rising demand for reliable busbars that can handle the stress of electric mobility. All of this aligns pretty well with

global efforts to cut down carbon emissions and promote sustainability.

With continuous innovation, the adoption of more advanced busbar solutions will definitely help smooth the way for a cleaner, greener future in transportation—and honestly, that’s

pretty awesome.

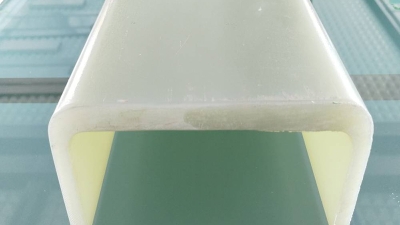

Maximizing Safety and Efficiency: The Benefits of EPGC Molded Electrical Insulation Profiles in Modern Applications

In today's fast-paced technological landscape, the reliability of electrical insulation is paramount. EPGC molded electrical insulation profiles present a significant advancement in safety and efficiency for various modern applications. Constructed from multi-layer epoxy glass cloth, these profiles are engineered under high temperatures and pressures, ensuring robust mechanical and electrical properties. This unique manufacturing process not only enhances durability but also allows for precise customization according to user specifications, a feature that is essential for industries demanding tailored solutions.

Available in various grades like EPGC201, EPGC202, EPGC203, EPGC204, EPGC306, and EPGC308, these molded profiles cater to diverse insulation needs. Their versatility allows for machining into specific structural parts that fit seamlessly into existing designs, promoting both functionality and safety. As industries continue to evolve, investing in high-performance insulation materials like EPGC molded profiles ensures that electrical systems operate efficiently while minimizing the risk of failures. By choosing EPGC insulation solutions, businesses can maximize their operational uptime and ensure the safety of their personnel and equipment.

FAQS

: The EV industry is experiencing significant trends, particularly with a growing demand for reliable charging systems and advanced busbar technologies, which are projected to grow at a CAGR of 11% through 2026.

Busbars are critical components for efficient power distribution in EV charging networks, supporting the increasing demand for fast charging options.

Industry players should focus on modular designs for scalability, improve thermal management through material advancements, and understand regional compliance regulations to streamline deployment.

Regulatory bodies need to balance safety and innovation in busbar technology, with existing standards often slowing the progress of manufacturers exploring novel materials and designs.

Regulations are increasingly emphasizing the need for eco-friendly materials in busbars while ensuring performance and durability, posing a challenge for manufacturers.

Future opportunities include improving energy distribution, reducing weight in electric vehicles, and developing advanced electrical insulation and structural integrity solutions.

Sichuan D&F Electric Co., Ltd. is dedicated to creating high-quality electrical connection components that address the challenges of electric vehicle infrastructure, focusing on sustainability and performance.

Collaboration between industry stakeholders and regulatory bodies is essential for navigating regulatory complexities and driving meaningful advancements in electric vehicle busbar technologies.

Leveraging data-driven insights is crucial for industry players to stay ahead of market trends and to address potential challenges effectively.

Sustainability is vital as it aligns with global initiatives to reduce carbon emissions, and ongoing innovations in busbar technology will support the transition to cleaner transportation options.

Conclusion

Hey, I recently came across a blog called "Identifying Challenges with Electric Vehicle Busbar Innovations," and honestly, it dives into all the tricky stuff folks are facing when trying to develop better electric vehicle busbars. It does a pretty good job of laying out what's happening in the EV infrastructure world right now. You know, the market trends and all that, but also points out some real technical limitations with current busbar designs—that stuff’s actually holding back performance and efficiency more than you'd think. Oh, and the choice of materials? That’s a big deal too. Getting it right can really make a difference in how well the busbars help the whole vehicle run smoothly. Plus, there's the whole regulatory side of things—laws and rules that innovators need to keep in mind so they stay compliant but still push the technology forward.

Now, Sichuan D&F Electric Co., Ltd., is a solid player in this game. They’ve got a good reputation for making electrical connection components and seem pretty committed to innovation. They're actually in a good spot to tackle these challenges head-on. Their focus on creating new solutions fits right into the emerging opportunities around busbar tech and sustainable transportation. Given how quickly things are changing in this space, their expertise in electrical insulation parts could really help overcome some of the current limits in EV busbars. Overall, their work could lead to more efficient and reliable electrical systems in electric vehicles—that’s pretty exciting, don’t you think?

Related Posts

-

How to Achieve Maximum Energy Efficiency with H Class Insulation Solutions

-

The Ultimate Checklist to Choosing the Best Copper Bus Bar for Global Procurement

-

Exploring the Unique Properties and Applications of Best Nomex T410 Film: A Comprehensive Guide for Buyers

-

Unlocking the Advantages of Bare Copper Strip in Electrical Applications for Energy Efficiency

-

Solutions for Enhancing Electrical Efficiency with Silver Plated Copper Bus Bars

-

Ultimate Guide to Choosing the Right Flexible Busbar Connectors for Your Systems