Essential Checklist for Choosing the Right Glass Polyester Laminate for Your Project

Table of Contents

- Identifying Common Issues with Different Types of Glass Polyester Laminate

- Understanding Durability Concerns in Glass Polyester Laminates

- Evaluating Aesthetic Challenges in Glass Polyester Laminate Selection

- Assessing Cost Implications for Various Glass Polyester Laminate Types

- Exploring Environmental Considerations for Glass Polyester Laminates

- Tips for Troubleshooting Problems in Glass Polyester Laminate Projects

- Enhancing Composite Durability: The Impact of GPO-3 Laminated Sheets in Industry Applications and Market Trends

- FAQS

- Conclusion

- Related Posts

In the ever-changing world of electrical and construction materials, picking the right Glass Polyester Laminate really matters. It’s pretty much key to making sure your projects are durable and perform well. I’ve been looking into market trends lately, and it’s interesting—demand for composite materials like Glass Polyester Laminates is actually expected to keep growing at a steady rate of over 5% annually until 2026. That’s mainly because they offer great mechanical strength and handle environmental challenges like a champ. Oh, and if you didn’t know, Sichuan D&F Electric Co., Ltd., started back in 2005 and has built a solid reputation as a trustworthy manufacturer and supplier of electrical connection parts and insulation components right in the heart of Sichuan, China. When choosing the right laminate, it really helps to consider things like thermal stability, chemical resistance, and overall mechanical strength—these factors can really make a difference in how long and reliable your electrical setups turn out. To make things easier, I’ve put together this handy checklist that’ll walk you through selecting the perfect Glass Polyester Laminate, tailored just for your specific needs.

Identifying Common Issues with Different Types of Glass Polyester Laminate

When you're choosing the right glass polyester laminate for your project, it's pretty important to know about some of the common issues that can crop up with different types. One of the more frequent problems is warping, which often happens if the curing process isn’t done quite right. Warped laminates can really mess with the strength and stability of your build, so making sure the manufacturing process is spot-on is super important. Plus, watch out for delamination — that's when the layers start to peel apart over time. This usually happens if the adhesion isn’t great or if moisture gets in, so it’s definitely a good idea to pick products that have a solid track record for holding up in different environments.

Another thing to keep in mind is how well the laminate resists UV rays. Some types don’t handle sunlight that well, which can lead to fading or becoming brittle—definitely not what you want, especially if you’re working outdoors or in sunny spots. Checking how resistant the material is to UV exposure is a smart move if you want your project to last. By being aware of these common pitfalls—warping, delamination, and UV damage—you can pick the best material and set yourself up for a successful, long-lasting project.

Understanding Durability Concerns in Glass Polyester Laminates

When you're trying to pick the right glass polyester laminate for your project, it's super important to really understand the durability aspect. These laminates are known for being strong and pretty resistant to all sorts of environmental stuff, which is why they’re often used in electrical insulation and structural parts. But, here's the thing—how durable they are can actually change a lot depending on the specific formulation and how they’re made. So, it’s a good idea to look into how well the laminate stands up against moisture, temperature changes, and chemicals. You want to make sure it can handle whatever your project throws at it.

Here's a quick tip: always take a peek at the manufacturer’s specs—especially the parts about how the material resists different environmental conditions that matter for your use. A solid supplier like Sichuan D&F Electric Co., Ltd. can really help you out by providing detailed info on how durable and reliable their products are. That way, you’re making a smarter, more informed choice.

Also, don’t forget to think about the laminate’s mechanical strength and impact resistance. You want something that can handle stress without bending or cracking—because that’ll help your project last longer. If you’re ever unsure, it’s definitely worth talking to folks who know their way around glass polyester laminates—getting their advice can really make a difference.

And here's another tip: check for third-party certifications or test results. They’re a good way to verify what the manufacturer claims about durability—giving you a bit more peace of mind that your laminate will hold up even in tough conditions.

Evaluating Aesthetic Challenges in Glass Polyester Laminate Selection

When you're choosing a glass polyester laminate for your project,

remember that aesthetics really matter.

The right choice can totally change how a space feels and looks. First off, you'll want to think about

color schemes and finishes that match your overall design vibe. These laminates come in all

sorts of textures and colors—glossy, matte, you name it—which gives you a lot of room to play with light

and shadows. It's also a good idea to see how they blend with your existing decor; that way, everything

feels cohesive and put together.

Oh, and don't forget about transparency and translucency. Depending on the mood you're

after, some laminates that diffuse light can soften the atmosphere and make things a bit more cozy.

On the other hand, clear or shiny finishes pop in a modern, sleek

way and can give the space a more contemporary look. Balancing these details isn’t always straightforward,

but it’s worth thinking about because they affect both how everything looks and how the space functions.

If you take a moment to consider these aesthetic details, you'll end up with a laminate that really elevates

your project and makes it look fantastic.

Assessing Cost Implications for Various Glass Polyester Laminate Types

When you're trying to figure out the costs involved with different types of glass polyester laminates for your project, it’s really important to think about both the upfront material costs and what you’ll get in the long run. I came across a report from the Global Composites Market that says the price of these laminates can vary quite a bit—somewhere between $5 and $25 per square meter—depending on the formulation and the manufacturer. That kind of range just shows how critical it is to pick a laminate that not only fits your budget but also does the job you need it to.

And don’t forget, the initial price isn’t everything. It’s worth considering the life cycle costs too. According to research from the Structural Composites Institute, opting for higher-quality laminated products can actually give you over 30% better durability and better resistance to environmental wear and tear compared to cheaper options. That kind of quality can really pay off over time by saving you money on repairs and replacements. In the end, it’s all about finding that sweet spot — balancing a sensible upfront investment with solid long-term performance so you get the most bang for your buck and make sure your resources go as far as possible.

Exploring Environmental Considerations for Glass Polyester Laminates

When you're choosing glass polyester laminates for your project, it's more important than ever to think about environmental factors. Recent research shows that things like UV rays and humidity can really impact how these materials hold up over time. For example, glass fiber reinforced polymer composites tend to break down noticeably when exposed to strong sunlight, which can make them less strong and durable. It’s pretty crucial to understand these environmental stressors because they directly affect how long your laminates will last and how well they perform—whether you're dealing with marine settings, construction sites, or other tough environments.

Plus, the kind of resin system and the way you make these laminates also play a big role in how they hold up environmentally. Studies suggest that using modified resin systems can boost their strength and also help them resist aging and environmental damage better. And as everyone’s moving towards greener choices, exploring alternatives like natural fiber composites might be a smart way to cut down on ecological impact. So, making an informed decision that considers these environmental factors can really help ensure your laminates stay reliable and perform their best, all throughout their lifecycle.

Essential Checklist for Choosing the Right Glass Polyester Laminate for Your Project - Exploring Environmental Considerations for Glass Polyester Laminates

| Criteria | Details |

|---|---|

| Material Composition | High-quality glass fibers reinforced with polyester resin |

| Environmental Impact | Sustainable sourcing and manufacturing processes |

| Durability | Excellent resistance to moisture, chemicals, and UV light |

| Weight | Lightweight compared to traditional materials, facilitating easier installation |

| Aesthetic Options | Available in a variety of colors, finishes, and patterns for design flexibility |

| Cost-Effectiveness | Competitive pricing with long-term durability savings |

| Recyclability | Options available for recycling after end-of-life use |

Tips for Troubleshooting Problems in Glass Polyester Laminate Projects

When you're working on glass polyester laminate projects, it's pretty normal to run into some issues now and then. The key is knowing how to troubleshoot effectively—trust me, it can really make or break the final quality of your work. First off, take a good look at the laminate surface. Things like bubbles or areas where the layers are coming apart (delamination) are common problems, and they can weaken the structure if you don't deal with them quickly. Sometimes, a little heat can help get rid of tiny bubbles, but if you've got delamination, you might need to patch it up or replace that section altogether.

Another thing to keep an eye on is how well the laminate bonds to the surface underneath. If it doesn’t stick properly, that can lead to bigger issues down the road. Double-check that the surface was prepared right—clean, with the right profile—and make sure you're using the proper adhesive. Giving it enough time to cure properly is also super important. And don’t forget about environmental factors! Things like temperature and humidity can really mess with how well the laminate performs. Spotting these issues early and fixing them on the spot can really boost the durability and look of your project, making sure it turns out just how you want it.

Essential Checklist for Choosing the Right Glass Polyester Laminate

This bar chart illustrates the importance ratings of different factors to consider when choosing a glass polyester laminate for projects, such as color variety, durability, cost, weight, and finish quality.

Enhancing Composite Durability: The Impact of GPO-3 Laminated Sheets in Industry Applications and Market Trends

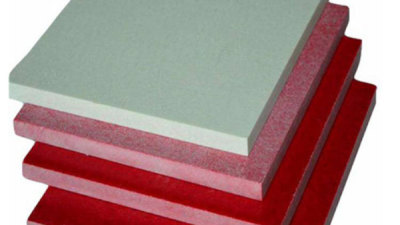

In today’s evolving industrial landscape, the demand for materials that offer enhanced durability and performance has never been greater. The emphasis on innovative solutions leads us to GPO-3 laminated sheets, also known by their other identifiers such as GPO3, UPGM203, and DF370A. These molded sheets represent a significant advancement in composite materials, consisting of alkali-free glass mat that is meticulously impregnated and bonded with unsaturated polyester resin, then laminated under controlled high temperatures and pressures. The outcome is a product that not only boasts excellent machinability and high mechanical strength but also surpasses expectations in dielectric properties, making it ideal for various industrial applications.

According to research from the Composite Manufacturing Association, the aerospace and electrical sectors are increasingly adopting materials like GPO-3 for their superior proof tracking and arc resistance capabilities. In environments where electrical insulation is paramount, GPO-3's UL certification and compliance with REACH and RoHS standards make it a reliable choice. The ability of GPO-3 to withstand harsh conditions without compromising performance positions it as a leader in today's market, with an increasing trend projected in demand across several applications. Reports indicate that the growing focus on energy efficiency and safety regulations will further drive this trend, underscoring the importance of integrating durable materials in modern manufacturing processes.

The versatility of GPO-3 laminated sheets is further enhanced by their adaptability to various industries, from automotive to telecommunications, where reliability and durability are non-negotiable. As companies continue to pivot towards sustainable and high-performance materials, GPO-3 stands out not only as a composite that meets these industry standards but also as a strategic asset for businesses looking to innovate and enhance their product offerings.

FAQS

: The average cost of glass polyester laminate typically falls between $5 to $25 per square meter, depending on the specific formulation and manufacturer.

Considering life cycle costs is essential because high-quality laminated products can offer over 30% better durability and resistance to environmental degradation, leading to significant savings in maintenance and replacement costs over time.

Environmental factors such as UV radiation and humidity can significantly affect the performance and durability of glass polyester laminates, potentially leading to degradation and reduced mechanical properties.

The choice of resin systems can greatly influence the environmental performance and mechanical properties of glass polyester laminates, with modified resin systems enhancing tensile properties and resistance to aging.

Exploring alternatives like natural fiber composites can provide eco-friendly options that reduce the ecological footprint compared to traditional materials.

It's important to balance upfront investment with long-term performance efficiency to ensure that the selected laminate meets both budgetary constraints and project performance requirements.

Environmental stressors, such as high levels of UV radiation, can lead to degradation of laminates, affecting their longevity and functionality in applications like construction or marine environments.

High-quality laminated products demonstrate improved durability and can result in reduced maintenance and replacement costs, making them a more economically feasible option in the long run.

Understanding the impact of UV radiation is crucial because it can lead to significant degradation in performance, which affects the effectiveness of the laminate in various applications.

As sustainable practices gain importance, considering options like modified resin systems and natural fiber composites can mitigate the ecological impact of laminate production and use.

Conclusion

When you're choosing the right Glass Polyester Laminate for your project, there's quite a few things to keep in mind. First off, getting familiar with common issues that can pop up with different types of laminates can really help you make smarter choices. Durability’s also a big deal—some laminates hold up better against weather and other stressors than others, so it’s worth considering how hardy you need it to be. And of course, don’t forget about how it looks; the aesthetic side is super important because it can really make or break the overall vibe of your project.

Budget-wise, prices can vary a lot depending on the type of laminate you pick, so it’s a smart move to weigh your options against what you’re willing to spend. These days, environmental factors are more important than ever, so thinking about eco-friendly options is definitely worth it. Lastly, it’s a good idea to have a game plan for troubleshooting any issues that might come up during installation or later on. If you take the time to thoughtfully consider all these factors, you'll be much more likely to pick a laminate that not only looks great but also serves your needs well, making your project turn out just how you imagined.

Related Posts

-

The Future of China Epoxy Glass Fiber Sheet in Global Markets

-

Exploring Alternative Options to Best Gpo3 Sheets for Savvy Global Buyers

-

Solutions for Enhancing Electrical Efficiency with Silver Plated Copper Bus Bars

-

How to Choose the Right Flexible Busbar Solutions for Your Industrial Needs

-

Unlocking the Advantages of Bare Copper Strip in Electrical Applications for Energy Efficiency

-

Global Market Insights: Projecting the Future of Best Epoxy Fiberglass Tubes by 2025