7 Tips for Choosing the Right Copper Bus Bar Manufacturer in Spain

Table of Contents

- Evaluating Manufacturer Experience in Copper Bus Bar Production: Key Metrics and Years in Business

- Understanding Material Quality Standards: Importance of ASTM B-187 Compliance for Bus Bars

- Assessing Customization Capabilities: Can the Manufacturer Meet Your Unique Specifications?

- Reviewing Client Testimonials and Case Studies: Analyzing Success Rates in Project Deliveries

- Exploring Certification and Compliance: Ensuring ISO 9001 Standards in Copper Manufacturing Processes

- Analyzing Supply Chain Efficiency: The Impact of Logistics on Lead Times and Delivery Reliability

- The Essential Guide to Custom Rigid Copper and Aluminum Bus Bars for Optimal Electrical Performance

- FAQS

- Conclusion

- Related Posts

Picking the right Copper Bus Bar Manufacturer in Spain isn’t just a detail—it’s a pretty big deal when it comes to making sure your electrical systems are top-notch and reliable. Nowadays, with everyone looking for more efficient electrical connections, it can feel a bit overwhelming to sort through all the different manufacturers out there. You need a partner who not only ticks all your technical boxes but also understands your business needs. That’s where a solid manufacturer and supplier like Sichuan D&F Electric Co., Ltd. comes into play. They've been around since 2005, and over the years, they’ve built a reputation for quality and innovation. They’re based in the Jinshan industrial park in Deyang, Sichuan, China—just a bit of background for you. When choosing a Copper Bus Bar supplier, it really pays to consider things like their production capacity, certifications, and how supportive they are with customer service. Making the right choice here can make a real difference, helping your operations run smoother and safer overall.

Evaluating Manufacturer Experience in Copper Bus Bar Production: Key Metrics and Years in Business

So, when you're trying to pick a copper bus bar manufacturer in Spain, one of the first things you probably wanna check out is how much experience they’ve got under their belt in making bus bars. Honestly, a company that's been around for a while often knows the ropes—how to stay ahead of market trends and use the latest tech. Industry chatter often points out that firms with over 10 years of experience usually have a better handle on quality control and production stuff, which really affects how well your electrical systems will work.

But experience isn't everything. You also wanna look at their capacity—like, can they handle big orders? And do they use modern tech? Companies that invest in up-to-date manufacturing methods tend to deliver top-notch copper bus bars that meet current sustainability demands. That’s especially important these days, with electric vehicles becoming more popular and the big need for reliable battery components, bus bars are in hot demand.

Here's a little advice: First, see if they care about sustainability — it’s pretty crucial now, especially if you're working with electric vehicles. Next, ask about their certifications and whether they play by the international rules—stuff that just guarantees their quality and reliability. And don’t forget to check out some reviews or case studies that show they’ve handled big projects before. That gives you a good idea of their experience level and how smooth they might be to work with.

7 Tips for Choosing the Right Copper Bus Bar Manufacturer in Spain

| Manufacturer Experience (Years) | Monthly Production Capacity (kg) | Certifications | Industry Focus | Customer Satisfaction Score (0-10) |

|---|---|---|---|---|

| 15 | 5000 | ISO 9001, CE | Electrical, Industrial | 9 |

| 10 | 3000 | ISO 14001 | Renewable Energy | 8 |

| 20 | 7000 | UL, RoHS | Telecommunications | 10 |

| 12 | 4500 | ISO 9001, OHSAS | Manufacturing, Automotive | 7 |

Understanding Material Quality Standards: Importance of ASTM B-187 Compliance for Bus Bars

So, if you're trying to pick a copper bus bar supplier in Spain, it's pretty important to know about stuff like ASTM B-187 standards. Basically, this certifies that the copper bus bars meet certain mechanical and electrical performance benchmarks. And honestly, that’s a big deal because it ensures they’ll be reliable in different setups. When manufacturers stick to these standards, you can trust their products will have good conductivity and resist corrosion better, which means your electrical systems will last longer and work more efficiently.

On another note, recent developments in metal 3D printing—like additive manufacturing—have shown just how crucial material quality really is. Flaws during production can seriously throw off the mechanical strength of metal parts. It’s kind of like how quality standards are key for bus bars too. Using advanced tools like X-ray tomography can help manufacturers catch and fix these issues early on. That way, they’re not just ticking the box for ASTM B-187 compliance, but also making sure their products perform well across different conditions — basically, giving them the edge for durability and reliability.

Assessing Customization Capabilities: Can the Manufacturer Meet Your Unique Specifications?

When you're on the hunt for a copper bus bar manufacturer in Spain, it's really important to check out how well they can customize their products. I mean, their ability to handle those unique specs can totally make a difference in how well your electrical systems perform and how efficient they are. It’s a good idea to chat with potential suppliers about their production process, what kind of tech they use, and maybe even ask about past projects where they had to get pretty creative. Keep an eye out for signs they’re flexible with design—someone who's willing to work closely with you to craft the perfect solution is always a plus.

Here at Sichuan D&F Electric, we’ve been into customizing electrical connection parts and insulation components since way back in 2005. We’ve built a reputation for delivering top-notch quality products that really match what our clients need. Thanks to our advanced manufacturing techniques, we can create special parts tailored to your specific requests, making sure everything fits perfectly and performs at its best. Picking a manufacturer that values customization like this can actually give you a pretty nice edge in the market.

Reviewing Client Testimonials and Case Studies: Analyzing Success Rates in Project Deliveries

When you're looking for a copper bus bar manufacturer in Spain, one of the biggest things to keep in mind is their track record—stuff you can usually find in client reviews and case studies. It’s worth digging into what past customers have to say because those reviews can really tell you a lot about how reliable they are, the quality of their work, and whether they stick to deadlines. If you see lots of positive feedback, it’s often a sign they communicate well and are responsive—that’s super important when you're trying to get a project done smoothly.

Apart from customer reviews, taking a look at detailed case studies can be super helpful. They usually highlight specific challenges a manufacturer faced on previous projects and how they managed to tackle them. Going through these examples gives you a pretty good idea of their problem-solving skills and whether they can adapt to different situations. All this info helps you make a smarter decision—not just for what you need right now, but also considering your long-term goals working with a manufacturer in the future.

Exploring Certification and Compliance: Ensuring ISO 9001 Standards in Copper Manufacturing Processes

When you're out there looking for a copper bus bar manufacturer in Spain, one of the big things you really wanna check is if they follow ISO 9001 standards. This certification is pretty much a mark of quality around the globe, showing that they have a solid system in place for maintaining consistent quality. Honestly, companies that stick to ISO 9001 tend to cut down on product defects by as much as 30%, which means their stuff is more reliable and performs better in electrical setups. Going for a supplier with this certification gives you peace of mind, knowing they’re serious about quality and always aiming to get better.

But yeah, certifications are just part of the picture. It’s also smart to see how they handle environmental and safety rules—those are good indicators of how they run things behind the scenes. A manufacturer who plays by the rules is more likely to care about sustainable practices and invest in new tech, which is a win-win. Here’s a couple of quick tips: first, don’t just take their word for it—ask to see their certificates. And second, check out their production process. The best ones won’t mind sharing how they do things and will be transparent about their standards to make sure they’re compliant with both local and international laws. If you keep these points in mind, you’ll be in a pretty good spot to pick the right copper bus bar supplier in Spain.

Compliance Levels of Copper Bus Bar Manufacturers in Spain (ISO 9001 Standards)

Analyzing Supply Chain Efficiency: The Impact of Logistics on Lead Times and Delivery Reliability

When you're trying to pick a copper bus bar manufacturer in Spain, it’s pretty important to get a good grip on how efficient their supply chain actually is. I mean, logistics really shapes how quickly things get delivered and whether they arrive on time.

A solid, well-organized supply network can help cut down on delays, making sure that manufacturers stick to their production schedules and keep materials flowing smoothly.

Things like how they handle transportation, their warehouse setup, and managing inventory all play big roles in how fast and reliable their delivery actually is.

Plus, where the manufacturer is located matters too. If they’re close to major shipping hubs, chances are they'll have better access to routes, which means faster deliveries. Good communication with suppliers and working together closely can also make a big difference — it helps you respond quickly when market demands shift.

So, taking a good look at a manufacturer’s supply chain setup can tell you a lot about whether they’ll be able to keep up with your needs and deliver copper bus bars on time, which is super important if your own production relies on having these materials readily available.

The Essential Guide to Custom Rigid Copper and Aluminum Bus Bars for Optimal Electrical Performance

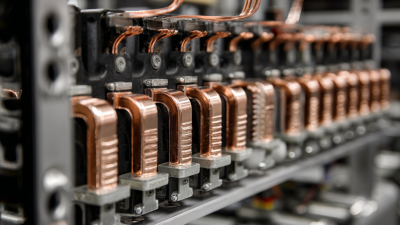

In the realm of electrical engineering, the performance of systems depends greatly on the quality of the components used. One crucial element is the bus bar, which serves as a conductive pathway for electricity. Sichuan Myway Technology Co., Ltd. leads in this field, boasting over 17 years of CNC machining experience dedicated to the fabrication of high-quality rigid copper and aluminum bus bars. These products are meticulously crafted to meet specific user requirements, ensuring that each bar adheres to precise technical specifications.

Rigid copper bus bars are predominantly used due to their excellent conductivity and durability. Fabricated from copper or aluminum sheets and bars, these conductors come in long rectangular shapes and can feature either a standard rectangular cross-section or a chamfered design. The rounded edges of chamfered bus bars are particularly advantageous, as they mitigate the risk of point discharge, enhancing the safety and efficiency of electrical connections. By providing reliable current conveyance and robust connectivity to electrical equipment, Myway Technology’s bus bars are essential for optimizing electrical performance in any circuit configuration.

FAQS

: ISO 9001 certification ensures that manufacturers maintain a consistent quality management system, which is essential for delivering high-quality copper products. Compliance can reduce product defects by up to 30%.

You can verify a manufacturer’s ISO certification by requesting documentation that demonstrates their compliance with the standard.

Compliance with environmental and safety regulations reflects a manufacturer’s operational integrity and commitment to sustainable practices and innovative technologies.

Factors such as transportation methods, warehousing capabilities, inventory management, and the geographic location of the manufacturer significantly influence supply chain efficiency and delivery reliability.

A manufacturer located near major transport hubs may have better access to shipping routes, leading to faster delivery times.

Evaluate the manufacturer’s supply chain capabilities, including their logistics, response time to market demands, and consistency in product availability.

A well-organized supply chain minimizes delays by ensuring efficient transportation and material flow, which directly affects lead times.

Timely access to copper bus bars is crucial for businesses reliant on these products for their own manufacturing processes, as delays can disrupt production schedules.

Manufacturers compliant with ISO 9001 demonstrate a commitment to quality and continuous improvement, giving buyers confidence in the reliability and performance of their products.

Examine their production processes and standards, and ensure they are transparent about their compliance with both local and international regulations.

Conclusion

Picking the right copper bus bar manufacturer in Spain isn’t just about flipping through a list — it’s about really digging into a few key things. First off, you want to get a sense of their experience — how long have they been doing this, and what’s their track record? That gives you a good idea if they’re reliable or not. It’s also super important to check if they stick to industry standards, especially ASTM B-187, to make sure their products are up to scratch. Another thing to consider is whether they’re flexible enough to customize their offerings to match the specific needs of your project — sometimes one size won’t fit all, right?

It helps to read through reviews or case studies to see how they’ve handled previous projects. And don’t forget, certifications like ISO 9001 can tell you a lot about their manufacturing process and quality control. Finally, taking a closer look at how they manage their supply chain can make a big difference — prompt delivery and reliable logistics can save you a lot of headaches down the line. All in all, by looking at these different factors carefully, you’ll be in a much better position to choose a copper bus bar manufacturer in Spain that genuinely meets your needs.

Related Posts

-

The Ultimate Checklist to Choosing the Best Copper Bus Bar for Global Procurement

-

Solutions for Enhancing Electrical Efficiency with Silver Plated Copper Bus Bars

-

The Future of China Epoxy Glass Fiber Sheet in Global Markets

-

Essential Checklist for Choosing the Right Glass Polyester Laminate for Your Project

-

How to Optimize Your Production Process with Gpo-3 Plastic for Efficiency and Sustainability

-

How to Choose the Right Flexible Copper Strip for Optimal Electrical Performance