How to Choose Insulation Bus Bar for Electrical Systems?

Table of Contents

- Understanding the Basics of Insulation Bus Bars in Electrical Systems

- Key Factors to Consider When Selecting Insulation Bus Bars

- Materials and Their Impact on Insulation Bus Bar Performance

- Evaluating Voltage and Current Ratings for Bus Bars

- Thermal Management and Its Importance in Bus Bar Selection

- Industry Standards and Regulations for Insulation Bus Bars

- Best Practices for Installation and Maintenance of Bus Bars

- Efficient Power Distribution Solutions: Exploring Custom Copper Foil and Flexible Copper Braid Bus Bars

- FAQS

- Conclusion

- Related Posts

Picking the right insulation bus bar for your electrical setup can actually feel pretty tricky sometimes. I mean, it’s a pretty important part of making sure everything runs smoothly. Basically, this little component helps manage the electrical current, so getting it right can really boost your system’s efficiency and last longer. When you’re choosing one, keep in mind things like the voltage it needs to handle and the environment where it’ll be used. The materials should be tough enough to withstand heat and resist corrosion — nobody wants those issues creeping in. Oh, and don't forget to pick a supplier you can trust; quality can really vary out there. It’s worth thinking back on previous choices too — did they work out for you? Maybe you’ve had better luck with more durable options. Skipping over the specs or rushing your decision can end up costing you more later on, so it’s smart to do your homework and pick carefully. After all, what you choose today will affect how well your system performs down the line. So, take your time and make sure it’s a good fit — your future self will thank you!

Understanding the Basics of Insulation Bus Bars in Electrical Systems

Insulation bus bars are vital components in electrical systems. They help distribute power while minimizing energy loss. Understanding their basics is crucial for effective application. Insulation bus bars connect multiple circuits and prevent short circuits. They are typically made from materials like aluminum or copper and are coated for insulation.

Choosing the right insulation bus bar requires careful consideration. The voltage rating should match your electrical system's needs. The temperature rating is equally important. A bus bar that cannot handle high temperatures may fail. Additionally, it's essential to consider the environment where it's used. Corrosive or humid conditions can impact performance.

Commonly overlooked details include the thickness and width of the bus bar. These aspects should align with the current carrying capacity. If the bus bar is too thin, it may overheat. Conversely, an excessively large bus bar can add unnecessary weight. Design flaws can arise from ignoring these factors. Ultimately, the right insulation bus bar enhances safety and efficiency in electrical systems.

Key Factors to Consider When Selecting Insulation Bus Bars

When selecting insulation bus bars, there are key factors to evaluate. The first factor is the material. Copper and aluminum are commonly used. Each has its own conductivity and thermal characteristics. Consider the environment in which the bus bars will operate. Will they face high temperatures or corrosive elements?

Another crucial aspect is the voltage rating. Ensure that the insulation bus bar can handle the system's voltage levels. An insufficiently rated bar could lead to failures. The design also matters. It should facilitate the installation process and fit your electrical layout smoothly.

Tips: Always check the compatibility with existing components. This reduces the need for modifications. Conduct thorough testing before implementation. It can prevent future issues.

Look into the insulation properties. Different applications may require various insulation types. Some are better for high voltage, while others suit lower voltage systems. Reflect on your long-term goals too. Ensure your selection aligns with future upgrades or expansions.

Materials and Their Impact on Insulation Bus Bar Performance

When selecting insulation bus bars for electrical systems, materials play a crucial role in performance. Common materials include copper, aluminum, and various composites. Each has unique properties that can significantly influence conductivity and thermal performance. For instance, copper offers excellent conductivity but can be pricier. Aluminum, while lighter and more cost-effective, may have lower conductivity.

The choice of insulating materials also matters. Options like epoxy resin or silicone contribute to improved electrical insulation properties. However, it's essential to consider their thermal stability. If the insulation fails under heat, it creates risks. Sometimes, manufacturers prioritize cost over material integrity, which might lead to subpar performance.

Additionally, the environment where the bus bar will be used affects material choice. Humidity or exposure to chemicals can degrade certain materials over time. It's challenging to find the perfect balance. Some professionals may overlook these factors, assuming all materials perform the same. In reality, the wrong choice can lead to significant long-term issues.

Evaluating Voltage and Current Ratings for Bus Bars

When evaluating insulation bus bars for electrical systems, voltage and current ratings are critical factors. Voltage ratings determine the maximum potential difference that the bus bar can handle without risk of breakdown. This is crucial for ensuring the safety and efficiency of the entire system. Consider the environmental conditions. High humidity or extreme temperatures can affect the insulation quality and performance.

Current ratings indicate how much current the bar can carry safely. It's not just about the numbers; consider the application too. A bus bar used in a high-demand environment may need a higher rating than standard specifications suggest. Overloading can lead to overheating, potential failure, or even fire. When choosing, it’s essential to avoid merely relying on calculated values.

It’s important to reflect on the bus bar's longevity. Materials degrade over time, and insulation can wear down unexpectedly. Regular inspections can reveal issues early on. Don't overlook the physical layout in your design. Space constraints may impact installation and future maintenance, which can complicate upgrades down the line. Ultimately, a thorough understanding of these elements will lead to better, safer choices.

How to Choose Insulation Bus Bar for Electrical Systems? - Evaluating Voltage and Current Ratings for Bus Bars

| Bus Bar Material | Voltage Rating (V) | Current Rating (A) | Insulation Type | Application |

|---|---|---|---|---|

| Copper | 600 | 200 | PVC | Power Distribution |

| Aluminum | 500 | 150 | Polyester | Industrial Machinery |

| Copper | 1000 | 300 | Epoxy | Renewable Energy |

| Aluminum | 750 | 250 | Silicone | Commercial Equipment |

Thermal Management and Its Importance in Bus Bar Selection

Thermal management is crucial when selecting insulation bus bars for electrical systems. Effective thermal management can prevent overheating, ensuring safety and optimal operation. This involves selecting materials that can withstand high temperatures without degrading over time. The type of insulation also plays a key role. Materials vary in thermal conductivity, impacting how heat is dispersed. It's essential to choose wisely.

Moreover, consider the heat generated in your system. Higher currents produce more heat. Insufficient thermal management can lead to failures. Some designs struggle to dissipate heat effectively. Engaging with a poorly designed system may result in short circuits or, worse, fires. Therefore, understanding the thermal characteristics of bus bars is critical.

In addition to material selection, layout matters too. A compact design might look appealing but can trap heat. Wider spaces allow for better airflow. Evaluating installation environments helps identify potential thermal challenges. Peaks in temperature can be problematic. Reflecting on how components interact in real-world conditions can lead to better choices.

Industry Standards and Regulations for Insulation Bus Bars

When selecting an insulation bus bar, compliance with industry standards is critical. The International Electrotechnical Commission (IEC) and the National Electrical Manufacturers Association (NEMA) provide guidelines for electrical installations. These standards ensure safety and reliability in high-voltage systems. They focus on tests for heat resistance, dielectric strength, and environmental durability. Adhering to these regulations minimizes failures and prolongs the system's lifespan.

Consider the materials used in bus bars. For example, copper is preferred due to its excellent conductivity. However, aluminum can be a cost-effective option when insulated properly. The choice of insulation type is also vital. Polyvinyl chloride (PVC) is common but may not withstand extreme temperatures. Fluoropolymer or silicone materials are better suited for harsh environments. Always inspect material certifications before purchase.

**Tips:** Look for UL-listed components. This ensures they meet safety standards. Think about future maintenance needs. Sometimes, ease of access is overlooked. Poor accessibility can lead to significant downtime during repairs. Be mindful of weight limitations. A heavier bus bar may cause stress on mounting structures.

Best Practices for Installation and Maintenance of Bus Bars

When installing and maintaining insulation bus bars, attention to detail is crucial. Ensure the surfaces are clean before installation. Dirt and debris can lead to poor connections and reduced efficiency. Always check the alignment. Misaligned bus bars can cause stress on the connections. This might lead to failures down the line, potentially causing serious issues.

Regular maintenance is essential for long-term performance. Inspect bus bars for any signs of wear or overheating. Look for discoloration, which may indicate a problem. Tightening connections periodically prevents potential failures. However, be careful not to over-tighten. This could damage the bus bar or accompanying components.

Documentation plays a key role in maintenance. Keep a record of inspections and any adjustments made. This helps in identifying patterns over time. If issues arise, having a detailed history can be beneficial. Embrace a proactive approach to maintenance. Waiting for problems to occur can lead to costly repairs or system outages.

Efficient Power Distribution Solutions: Exploring Custom Copper Foil and Flexible Copper Braid Bus Bars

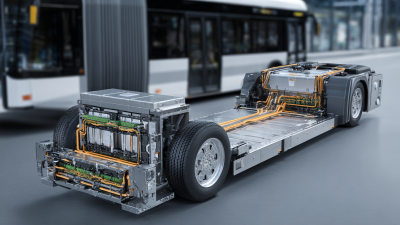

The demand for efficient power distribution solutions is driving innovation in flexible bus bars, particularly in the form of custom copper foil and flexible copper braid configurations. Flexible bus bars, often referred to as bus bar expansion joints or connectors, play a critical role in managing the challenges associated with thermal expansion and mechanical vibrations in electrical systems. By incorporating materials like copper foil and braided copper, these connectors provide reliable functionality while ensuring minimal resistance and optimal conductivity.

Flexible bus bars come in various forms, including copper foil flexible bus bars, copper strip flexible bus bars, and copper braid flexible bus bars. Each design is tailored to address specific application needs, such as compensating for deformation experienced during temperature fluctuations. Their versatility makes them particularly useful in battery packs and in the electrical connections between laminated bus bars, where movement and expansion are common. As technology evolves, the incorporation of these flexible solutions is essential to facilitate efficient power distribution in both new constructions and retrofitting existing systems.

FAQS

: The product aims to enhance user experience and improve daily tasks.

Read the instructions carefully. Follow the steps for best results.

Some users reported mild discomfort. Reactions can vary from person to person.

Consult a healthcare professional. Allergic reactions are possible with any product.

Check the usage guidelines. If issues persist, contact customer support for help.

Yes, there is a warranty. Terms and conditions apply; review them carefully.

Keep it in a cool, dry place. Avoid direct sunlight or excessive moisture.

Sharing is possible, but individual experiences may vary. Reflect on this before sharing.

Review instructions again. Try not to skip steps; they are designed for best outcomes.

Usage varies depending on personal preference. Balance is important; overuse may lead to issues.

Conclusion

When choosing an Insulation Bus Bar for electrical systems, it is essential to understand its fundamental role and functionality. This includes assessing key factors such as material selection, which significantly affects the performance of the bus bar, as well as evaluating voltage and current ratings to ensure compatibility with the electrical system. Moreover, thermal management plays a critical role in bus bar selection, as effective heat dissipation can prevent failures and enhance longevity.

In addition to technical specifications, it's crucial to consider industry standards and regulations that govern the use of Insulation Bus Bars. Adhering to these standards ensures safety and reliability in electrical installations. Finally, following best practices for installation and maintenance can further enhance performance and extend the lifespan of insulation bus bars, contributing to the overall efficiency and safety of the electrical system.

Related Posts

-

What is Electric Power Copper Bus Bar and Its Advantages for Electrical Systems

-

How to Choose the Right Metal Bus Bar for Your Electrical Needs

-

Essential Tips for Understanding Bus Bars in Electrical Systems?

-

How to Choose the Right Flexible Copper Strip for Optimal Electrical Performance

-

Identifying Challenges with Electric Vehicle Busbar Innovations

-

Unlocking the Advantages of Bare Copper Strip in Electrical Applications for Energy Efficiency