How to Choose the Right Epoxy Insulator for Your Electrical Projects

Table of Contents

- Understanding the Different Types of Epoxy Insulators Available

- Key Properties to Consider When Selecting Epoxy Insulators

- Evaluating Thermal and Electrical Resistance Requirements

- Assessing Environmental Impact: Choosing Durable Epoxy Insulators

- Compatibility with Existing Electrical Components and Systems

- Tips for Proper Installation and Handling of Epoxy Insulators

- Optimizing Performance and Reliability with DMC/BMC Molded Electrical Insulators in Modern Applications

- FAQS

- Conclusion

- Related Posts

In the fast-changing world of electrical engineering, picking the right components for your projects really matters. It’s all about safety, efficiency, and making sure everything lasts. One component that really stands out is the epoxy insulator. It’s known for its amazing dielectric strength, good thermal stability, and resistance to the elements—kind of a must-have in many setups.

Did you know that, according to a recent report from Grand View Research, the global epoxy resin market is expected to hit over $10 billion by 2025? That just shows how much folks are looking for high-performance insulating materials across different industries.

Choosing the right epoxy insulator can make a big difference—it helps reduce the risks of electrical faults and boosts the overall reliability of systems. Experts at the IEEE say that using epoxy insulators properly can even extend equipment lifespan by up to 50%. That’s pretty significant, right? As engineers and tech folks keep chasing after solutions that are both high-performing and sustainable, really understanding the ins and outs of epoxy insulators is going to be super important if we want to stay ahead of the game with new tech developments in electrical projects.

Understanding the Different Types of Epoxy Insulators Available

When choosing an epoxy insulator for electrical projects, understanding the various types available is crucial for ensuring optimal performance and reliability. Epoxy-based insulators are widely recognized for their excellent electrical properties and durability. Among the different types, the polyurethane and silicone rubber insulators are popular for their flexibility and resistance to moisture, while epoxy insulators stand out for their hardness and thermal stability, making them suitable for high-performance applications.

Recent studies indicate that the global subsea thermal insulation materials market is significantly influenced by epoxy and its derivatives, particularly in applications requiring exceptional thermal resistance. Epoxy insulators are preferred in extreme conditions, where moisture intrusion can be a concern, as highlighted in recent research exploring the damage mechanisms of moisture penetration in composite materials. This has led to advancements in formulations, particularly epoxy-anhydride systems, which enhance the thermal and mechanical properties of the insulators. Understanding these variations can help professionals select the most appropriate epoxy insulator for their specific electrical requirements, ensuring better energy management and asset protection in challenging environments.

How to Choose the Right Epoxy Insulator for Your Electrical Projects

| Type of Epoxy Insulator | Dielectric Strength (kV/mm) | Thermal Stability (°C) | Impact Resistance (J/m) | Recommended Applications |

|---|---|---|---|---|

| General Epoxy Insulator | 20 | -40 to 120 | 15 | Small electrical appliances |

| High-Temperature Epoxy Insulator | 25 | -50 to 180 | 10 | Motors and transformers |

| Low-Viscosity Epoxy Insulator | 30 | -40 to 150 | 8 | Sealing and potting applications |

| Electrical Grade Epoxy Insulator | 40 | -60 to 200 | 20 | High voltage applications |

Key Properties to Consider When Selecting Epoxy Insulators

When selecting epoxy insulators for electrical projects, several key properties must be considered to ensure optimal performance and longevity. One critical property is the dielectric strength, which measures the material's ability to resist electric breakdown. High-quality epoxy insulators typically have dielectric strengths exceeding 20 kV/mm. According to a study by the International Electrotechnical Commission, materials with superior dielectric properties enhance a system’s efficiency by minimizing energy losses due to electrical discharges.

Thermal stability is another essential factor. As electrical systems often generate heat, the insulator must withstand elevated temperatures without degradation. Epoxy resins with a glass transition temperature (Tg) of 150°C or higher are recommended for high-performance applications, as they maintain their structural integrity under thermal stress. The ASTM D648 standard outlines testing methods for determining heat deflection temperature, ensuring that the chosen epoxy insulator can perform effectively in hot operating conditions. Selecting the right epoxy insulator with the appropriate thermal and dielectric properties can significantly influence the overall reliability and effectiveness of electrical systems.

Evaluating Thermal and Electrical Resistance Requirements

When selecting the right epoxy insulator for your electrical projects, evaluating thermal and electrical resistance requirements is crucial. The thermal resistance of an epoxy insulator determines its ability to withstand heat generated by electrical currents without degrading. High-performance projects often involve components that operate at elevated temperatures, making it essential to choose an epoxy formulation with a high thermal stability rating. Look for products that can maintain their integrity in high-temperature environments, as this will ensure the longevity and reliability of your electrical systems.

Equally important is the electrical resistance of the epoxy insulator, which prevents electrical current from leaking between components. A good insulator should have a high dielectric strength to withstand the voltages present in your applications. When assessing electrical resistance, consider both the material's volume resistivity and surface resistivity, as these properties will affect its performance in various conditions, including humidity and contamination. By carefully analyzing these thermal and electrical requirements, you can select an epoxy insulator that will provide optimal performance and safety for your electrical projects.

Assessing Environmental Impact: Choosing Durable Epoxy Insulators

When selecting an epoxy insulator for electrical projects, considering its environmental impact is essential. Durable epoxy insulators are designed to withstand harsh conditions, thereby reducing the need for frequent replacements, which can contribute to waste. Choosing high-quality materials not only ensures longevity but also helps minimize the environmental footprint associated with manufacturing and disposing of less durable products.

When selecting an epoxy insulator for electrical projects, considering its environmental impact is essential. Durable epoxy insulators are designed to withstand harsh conditions, thereby reducing the need for frequent replacements, which can contribute to waste. Choosing high-quality materials not only ensures longevity but also helps minimize the environmental footprint associated with manufacturing and disposing of less durable products.

Moreover, it is crucial to assess the sourcing and production processes of epoxy insulators. Opting for products made from sustainable materials and those that utilize eco-friendly manufacturing practices can significantly reduce environmental harm. By prioritizing insulators that meet rigorous environmental standards, you can play a part in promoting sustainability in electrical applications while ensuring the reliability and safety of your projects.

Compatibility with Existing Electrical Components and Systems

When selecting an epoxy insulator for electrical projects, compatibility with existing components and systems is crucial. According to a report by IPC, a leading standard organization for the electronics industry, approximately 30% of electrical failures are attributed to insulation breakdowns due to incompatibility. Epoxy insulators come in various formulations, and selecting the right type ensures that the insulation withstands the environmental and operational conditions specific to your project.

Another aspect to consider is the thermal and chemical resistance of the epoxy material. A study by the Electric Power Research Institute highlights that epoxy insulators with enhanced chemical resistance can outperform traditional insulating materials by up to 25% in harsh environments. This is particularly significant for projects involving high voltages or exposure to corrosive substances. Ensuring that the epoxy insulator is compatible with the materials used in your existing systems can significantly prolong the lifespan of your electrical components and prevent costly downtimes.

Tips for Proper Installation and Handling of Epoxy Insulators

When handling epoxy insulators for electrical projects, proper installation is crucial to ensure optimal performance and safety. First and foremost, it’s essential to prepare the surface where the insulator will be applied. Clean the installation area thoroughly to remove any dust, grease, or contaminants that could compromise adhesion. Using a primer designed for epoxy can enhance bonding and help achieve a reliable seal. Make sure to follow the manufacturer’s specifications regarding curing times and temperatures, as these factors can significantly affect the quality of the installation.

In addition to surface preparation, handling epoxy insulators requires care to prevent accidental damage. Always wear appropriate personal protective equipment, including gloves and eyewear, to safeguard against epoxy exposure. When mixing epoxy components, take care to follow the recommended ratios to ensure proper curing. After installation, avoid excessive stress or exposure to extreme environmental conditions until the epoxy has fully cured. Following these tips not only enhances the longevity of your electrical project but also ensures the safety and reliability of your electrical systems.

Optimizing Performance and Reliability with DMC/BMC Molded Electrical Insulators in Modern Applications

In modern applications, the importance of optimizing performance and reliability cannot be overstated, particularly in the electrical industry. DMC (Density Molding Compound) and BMC (Bulk Molding Compound) molded electrical insulators have emerged as key components in achieving these objectives. Manufactured in specialized molds under high temperature and pressure, these insulators are engineered to meet stringent performance standards. Their unique composition allows them to withstand extreme conditions, making them ideal for various applications where reliability is paramount.

One of the standout features of DMC/BMC molded insulators is their customizability. Users can specify different withstand voltage levels, ensuring that the insulators are tailored to their specific operational needs. This flexibility empowers manufacturers to create insulators that not only meet standard electrical requirements but also exceed them, thereby enhancing the overall safety and longevity of electrical systems. The ability to adapt to various voltage tolerances makes DMC/BMC insulators an excellent choice for industries ranging from automotive to renewable energy, where performance and resilience are crucial.

FAQS

: Epoxy insulators are recognized for their excellent electrical properties, durability, hardness, and thermal stability, making them suitable for high-performance applications.

Polyurethane and silicone rubber insulators are popular for their flexibility and moisture resistance, while epoxy insulators excel in hardness and thermal stability.

Epoxy insulators are chosen for extreme conditions because they provide exceptional thermal resistance and are effective against moisture intrusion, which can damage other materials.

Recent advancements include epoxy-anhydride systems that enhance the thermal and mechanical properties of epoxy insulators, improving their performance in challenging environments.

Approximately 30% of electrical failures are attributed to insulation breakdowns due to incompatibility of insulation materials with existing components and systems.

Epoxy insulators with enhanced chemical resistance can outperform traditional materials by up to 25% in harsh environments, making them more reliable for high voltages and corrosive exposures.

Compatibility with existing electrical components, thermal and chemical resistance, and the specific environmental and operational conditions of the project are crucial factors.

Choosing the appropriate epoxy insulator can significantly prolong the lifespan of electrical components and prevent costly downtimes by ensuring reliable insulation performance.

Conclusion

When it comes to selecting the right epoxy insulator for your electrical projects, understanding the various types available is crucial. Different epoxy insulators cater to specific applications and environments, so evaluating their key properties, such as thermal and electrical resistance, is essential. Additionally, considering the environmental impact and durability of these insulators will ensure long-lasting performance in diverse conditions.

Compatibility with existing electrical components is another factor to keep in mind, as it ensures seamless integration within your systems. Finally, proper installation and handling of epoxy insulators play a significant role in their effectiveness. At Sichuan D&F Electric Co., Ltd., established in 2005 and a reliable supplier in the electrical connection and insulation industry, we emphasize the importance of these factors to help clients make informed decisions for their projects.

Related Posts

-

What Constitutes Busbar Insulator Material in Electrical Systems

-

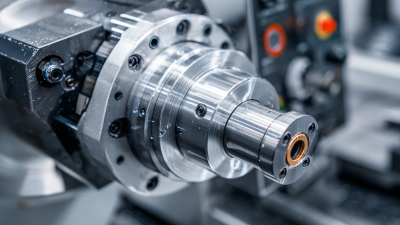

7 Essential Tips for Mastering Electrical Insulator Machining Efficiency

-

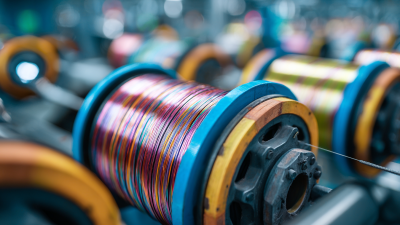

5 Key Insights on Winding Insulation Class for Optimal Motor Performance

-

How to Achieve a Durable Finish with Epoxy Bus Coating Techniques

-

Understanding the Advantages of Rigid Copper Busbars in Modern Electrical Systems

-

Understanding the Role of Electric Reactors in Renewable Energy Transition and Carbon Reduction