The Essential Role of Epoxy Insulators in Modern Electrical Systems: A Comprehensive Guide

Table of Contents

- The Importance of Epoxy Insulators in Electrical System Efficiency

- Types of Epoxy Insulators and Their Applications in Modern Technology

- Key Benefits of Using Epoxy Insulators Over Traditional Materials

- Installation Best Practices for Maximizing Epoxy Insulator Performance

- Future Trends in Epoxy Insulator Technology and Design Innovations

- Exploring the Benefits and Applications of DMC/BMC Molded Electrical Insulators in Modern Industries

- FAQS

- Conclusion

- Related Posts

You know, in today's fast-changing world of electricity, having top-notch components really makes all the difference—especially when it comes to epoxy insulators. These little guys might not grab all the headlines, but they’re absolutely crucial for keeping modern electrical systems running smoothly and long-lasting. They do a lot of heavy lifting, protecting against electrical failures and even shielding against the elements. At Sichuan D&F Electric Co., Ltd., we totally get how important well-designed connection parts and insulation components are for making sure everything works just right. Since 2005, right out of Jinshan Industrial Park in Deyang, Sichuan, we've been all about creating and providing trustworthy electrical solutions you can count on. This guide’s all about breaking down the key roles and perks of epoxy insulators today—why they’re such a durable, chemical-resistant, and heat-stable choice that keeps electrical systems safe and efficient, no matter what.

The Importance of Epoxy Insulators in Electrical System Efficiency

Epoxy insulators are pretty key when it comes to making modern electrical systems run smoothly. Thanks to their awesome electrical and mechanical qualities, they offer reliable insulation, which is absolutely vital for keeping various electrical components working properly. You know, industry reports are saying that the global market for cast resin transformers is set to grow pretty significantly. That’s mainly because more and more people are looking for high-performance electrical insulation solutions. Epoxy resins—especially when combined with anhydride curing systems—are proving to be super durable, which makes them perfect for all sorts of applications like power distribution and electrical utilities.

Lately, it feels like advances in materials science and engineering are really putting the spotlight on epoxy insulators. Innovations like electro-membrane processes, which recover lithium and boron, show how the industry is heading towards more sustainable practices. Experts often talk about how the careful formulations of epoxy-anhydride systems help ensure they perform well under all kinds of operating conditions. As companies like Sichuan D&F Electric keep pushing the boundaries of electrical insulation tech, it’s clear that epoxy insulators are having a real impact on improving the efficiency and reliability of electrical systems. All in all, they’re making power infrastructure more dependable than ever before.

Types of Epoxy Insulators and Their Applications in Modern Technology

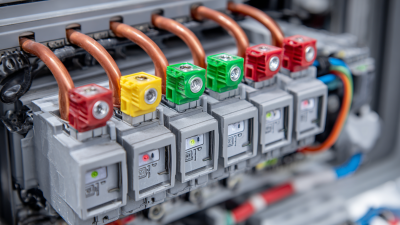

Epoxy insulators are pretty essential when it comes to modern electrical systems—they basically give crucial support and protection to a bunch of different components in all kinds of applications. There are actually a few types of epoxy insulators out there, each one designed to handle specific conditions and needs. For example, solid epoxy insulators are super common in high voltage setups because they have really good dielectric properties, which means they help keep everything running safely and smoothly in power distribution. You'll often see these in transformers and outdoor switchgear, where they act as a shield—preventing electrical breakdowns and protecting against weather stuff like rain and dirt.

Then there are epoxy resin insulators, which are known for their incredible strength and resistance to moisture. These are typically used in communication gear to keep signals clear and also lower the risk of short circuits. The cool thing is, epoxy formulas can be pretty easily tailored—so they can be made for special uses, whether it’s for wind turbines in renewable energy projects or even in really advanced aerospace tech. Basically, by picking the right kind of epoxy insulator, engineers can make electrical systems more reliable and last longer, helping push innovations forward in all sorts of tech fields.

Key Benefits of Using Epoxy Insulators Over Traditional Materials

These days, epoxy insulators are really gaining popularity in modern electrical setups, especially when you compare them to the classic materials like glass or ceramic. I came across a report from MarketsandMarkets that predicts the epoxy resin market will hit around $10.44 billion by 2026—that’s mainly because there's growing demand for more advanced materials in the electrical industry. One of the biggest perks of epoxy insulators is their high electrical resistance, which basically helps cut down power losses and makes systems run more efficiently. They have dielectric strengths that can go over 24 kV/mm, so they beat out a lot of traditional options—no wonder they’re the go-to for high-voltage stuff.

And here's the thing—epoxy insulators aren’t just good electrically; they’re tough against the elements, too. They can handle extreme temperatures and harsh conditions without breaking a sweat. A study I read in the IEEE Transactions on Dielectrics and Electrical Insulation pointed out that epoxy composites resist moisture and chemicals way better than older materials. Plus, with proper care, their lifespan can be extended by up to 50%, which is pretty impressive. That kind of durability not only means you save money on maintenance but also boosts reliability—super important if you want things to keep running smoothly without interruptions, especially with today’s fast-paced industry world.

The Essential Role of Epoxy Insulators in Modern Electrical Systems: A Comprehensive Guide

| Feature | Epoxy Insulators | Traditional Materials |

|---|---|---|

| Electrical Insulation Strength | High | Moderate |

| Thermal Stability | Excellent | Good |

| Chemical Resistance | Superior | Limited |

| Moisture Absorption | Low | High |

| Durability | Long-lasting | Wear over time |

| Application Areas | High voltage systems, aerospace | General electrical systems |

| Cost | Higher initial cost | Lower initial cost |

Installation Best Practices for Maximizing Epoxy Insulator Performance

When you're installing epoxy insulators in today's electrical setups, it's really important to follow some best practices. First off, prepping the installation spot is a must. That means not just cleaning the surface thoroughly where you'll place the insulator, but also making sure environmental factors like humidity and temperature are within the right range. If not, you might risk degrading the material over time. Also, using the right tools and handling techniques is key—this helps avoid damaging the insulator during installation and keeps everything in top shape.

On top of that, the way you install the insulator really makes a difference. It’s crucial to stick to the manufacturer’s guidelines for things like torque when tightening everything up. Overtightening might crack the insulator, and too loose? Well, that could mess with its electrical performance. It’s smart to think about adding moisture barriers and leaving some space for thermal expansion too—that can really boost how well the insulator performs. If you follow these tips, you’ll get the most out of those epoxy insulators, making sure they stay reliable and work efficiently in modern electrical systems.

Future Trends in Epoxy Insulator Technology and Design Innovations

You know, the way epoxy insulator technology is evolving is pretty exciting — it’s really set to shake up how we handle electrical systems nowadays. With folks demanding more durability and better performance, manufacturers are getting creative. One cool trend they’re working on is mixing nanomaterials into epoxy formulas, which makes the insulators stronger and better at handling heat. This means they can perform way better even in tough conditions, and they last longer too, which obviously cuts down on maintenance and downtime.

Oh, and by using advanced composite materials, these insulators are getting lighter and more efficient. That makes them easier to install and transport, which is a huge plus in the real world.

On top of that, design tweaks are a big deal right now. Companies are seriously focusing on shaping and structuring these insulators better — stuff like sleeker designs, smarter air gaps, and smoother surface finishes. All of that really helps improve how well they work and resist pollution. Plus, there’s a trend towards integrating smart tech, like sensors built right into the insulators. These let us keep an eye on their condition in real-time, so we can catch problems early and do proactive maintenance. All these innovations are shaping a future where epoxy insulators will be more reliable and robust, really meeting the needs of today’s modern infrastructure.

Exploring the Benefits and Applications of DMC/BMC Molded Electrical Insulators in Modern Industries

Molded electrical insulators, specifically those made from DMC (Dough Molding Compound) and BMC (Bulk Molding Compound) materials, are gaining significant traction in various modern industries due to their superior performance characteristics. These insulators are created using special molds under high temperature and high pressure, which not only enhances their structural integrity but also allows for a high degree of customization. According to a recent market report by ResearchAndMarkets, the demand for composite insulators is expected to grow substantially, driven by the increasing need for reliable and efficient electrical systems across sectors such as energy, telecommunications, and transportation.

One of the primary advantages of DMC/BMC molded electrical insulators is their impressive withstand voltage capacity. Manufacturers can tailor these insulators to meet specific voltage requirements, making them ideal for a wide array of applications, from high-voltage power transmission to low-voltage distribution systems. This adaptability is crucial, as industries are continually striving for materials that can withstand the rigors of varying electrical demands while maintaining safety and efficiency standards. The global electrical insulators market is projected to reach USD 17.5 billion by 2026, underscoring the critical role that advanced materials like DMC and BMC will play in this evolution.

Moreover, DMC/BMC insulators offer additional benefits including lightweight properties, resistance to thermal degradation, and excellent mechanical strength. These characteristics contribute to more efficient designs in modern electrical systems, reducing overall material requirements and enhancing installation ease. As industries continue to push for sustainable and cost-effective solutions, the development and use of custom insulators tailored to user specifications will become increasingly vital. This growing trend indicates a significant shift towards innovation and efficiency in many industrial applications.

FAQS

: The main types of epoxy insulators include solid epoxy insulators and epoxy resin insulators, each designed for specific high voltage and communication applications, respectively.

Solid epoxy insulators are commonly used in high voltage applications such as transformers and outdoor switchgear, providing protection against electrical breakdown and environmental factors.

Epoxy resin insulators offer excellent mechanical strength and moisture resistance, making them ideal for communication equipment where signal integrity and minimal short circuit risks are essential.

The versatility of epoxy formulations allows them to be customized for various applications, including renewable energy installations like wind turbines, enhancing reliability and longevity.

Future trends include the integration of nanomaterials for improved mechanical strength and thermal stability, leading to longer service life and reduced maintenance costs.

Design innovations that optimize shape and structure, such as streamlined designs with better air gaps and surface finishes, can significantly enhance electrical performance and pollution resistance.

Smart technologies integrated into insulation systems, like built-in monitoring capabilities, provide real-time diagnostics and condition monitoring, enabling proactive maintenance and reducing the risk of failures.

The incorporation of advanced composites results in lighter and more efficient designs for epoxy insulators, facilitating easier installation and transportation.

The development of epoxy insulator technology is crucial for meeting the growing demand for improved durability and performance in modern electrical systems.

By choosing the appropriate type of epoxy insulator, engineers can enhance the reliability and longevity of electrical systems, driving innovations across various technological fields.

Conclusion

Epoxy insulators are pretty crucial when it comes to making modern electrical systems more efficient and reliable. If you've read through the detailed guide on this stuff, you’ll see just how important they are — mainly because they actually do a better job than the old-school materials we used to rely on. You'll find them used in all sorts of industries, each type tailored to specific tech needs, offering top-notch electrical insulation and standing up well against environmental challenges.

That said, how you install these insulators really makes a difference. Doing it right helps them last longer and perform at their best over time. Looking ahead, new innovations in epoxy insulator tech are pretty exciting — they’re set to make these components even better and more flexible. As a company that’s been around and knows the ropes, Sichuan D&F Electric Co., Ltd. is dedicated to bringing these new advancements into their products, helping them stay ahead in the fast-changing world of electrical engineering.

Related Posts

-

Ultimate Guide to Choosing the Right Flexible Busbar Connectors for Your Systems

-

Exploring Insulation Class H Innovations at the 138th China Import and Export Fair 2025

-

Unlocking Efficiency: How Water Cooled Cold Plates Revolutionize Thermal Management in Electronics

-

The Future of China Epoxy Glass Fiber Sheet in Global Markets

-

How to Choose the Right Epoxy Fiberglass Sheets for Your Project

-

Essential Checklist for Choosing the Right Glass Polyester Laminate for Your Project