7 Essential Tips for Mastering Electrical Insulator Machining Efficiency

Table of Contents

- Understanding the Basics of Electrical Insulator Machining

- Choosing the Right Tools for Enhanced Machining Efficiency

- Optimizing Machining Settings for Precision and Speed

- Implementing Effective Quality Control Measures

- Keeping Up with Latest Trends and Technologies in Insulator Machining

- Maximizing Efficiency and Performance with Custom CNC Machining Insulation Structural Parts

- FAQS

- Conclusion

- Related Posts

In the fast-changing world of electrical manufacturing, really nailing efficiency when it comes to Electrical Insulator Machining is super important. It’s what helps companies stay ahead of the game and keeps their products reliable. I was reading a report from MarketsandMarkets, and it mentioned that the electrical insulator market is expected to hit around USD 18.3 billion by 2025, growing at a steady pace of about 4.8% annually. That kind of growth just highlights how crucial it is for manufacturers—like Sichuan D&F Electric Co., Ltd.—who’s been around since 2005 making connection components and insulation parts, to get really good at their machining processes. When they streamline these processes, they can slash production costs and boost the quality and lifespan of their products at the same time. In this post, I want to share seven practical tips that can help manufacturers sharpen their Electrical Insulator Machining game—so they tick all the boxes in today’s demanding electrical industry standards.

Understanding the Basics of Electrical Insulator Machining

When it comes to machining electrical insulators, getting a solid grip on the basics is really key if you want things to run smoothly and efficiently. These insulators are super important parts of electrical systems—they keep everything separated and need to hold up over time. Knowing what materials are used, like porcelain, glass, or composite stuff, is a big help because it guides you on what tools and techniques to use. Each material’s got its own quirks and requires specific cutting speeds, feed rates, and methods to get precise results and avoid wasting material.

Plus, it’s pretty important to be familiar with different machining methods like turning, milling, and grinding—without that, it’s hard to optimize production. Paying attention to things like tool wear, vibrations, or coolant application can really make a difference in how efficient your process is. Honestly, mastering these fundamentals sets the stage for you to adopt more advanced techniques and technologies down the line, making everything smoother and faster. By focusing on these basics, manufacturers can not only boost the quality of their electrical insulators but also improve overall productivity. It might seem a bit overwhelming at first, but trust me, it’s all about building that solid foundation for better results in the long run.

7 Essential Tips for Mastering Electrical Insulator Machining Efficiency

| Tip Number | Tip Description | Benefit | Implementation Difficulty |

|---|---|---|---|

| 1 | Choose the Right Tools and Equipment | Improved precision and reduced wear and tear | Medium |

| 2 | Regular Maintenance of Machinery | Prevents breakdowns and extends machine life | Low |

| 3 | Implement Efficient Workflow Practices | Increases productivity and reduces waste | Medium |

| 4 | Train Operators Thoroughly | Enhances machine handling and reduces errors | High |

| 5 | Monitor Production Metrics | Identifies bottlenecks and optimizes processes | Medium |

| 6 | Maintain an Optimal Environment | Enhances product quality and reduces defects | Medium |

| 7 | Adopt Automation Where Possible | Increases efficiency and reduces manual errors | High |

Choosing the Right Tools for Enhanced Machining Efficiency

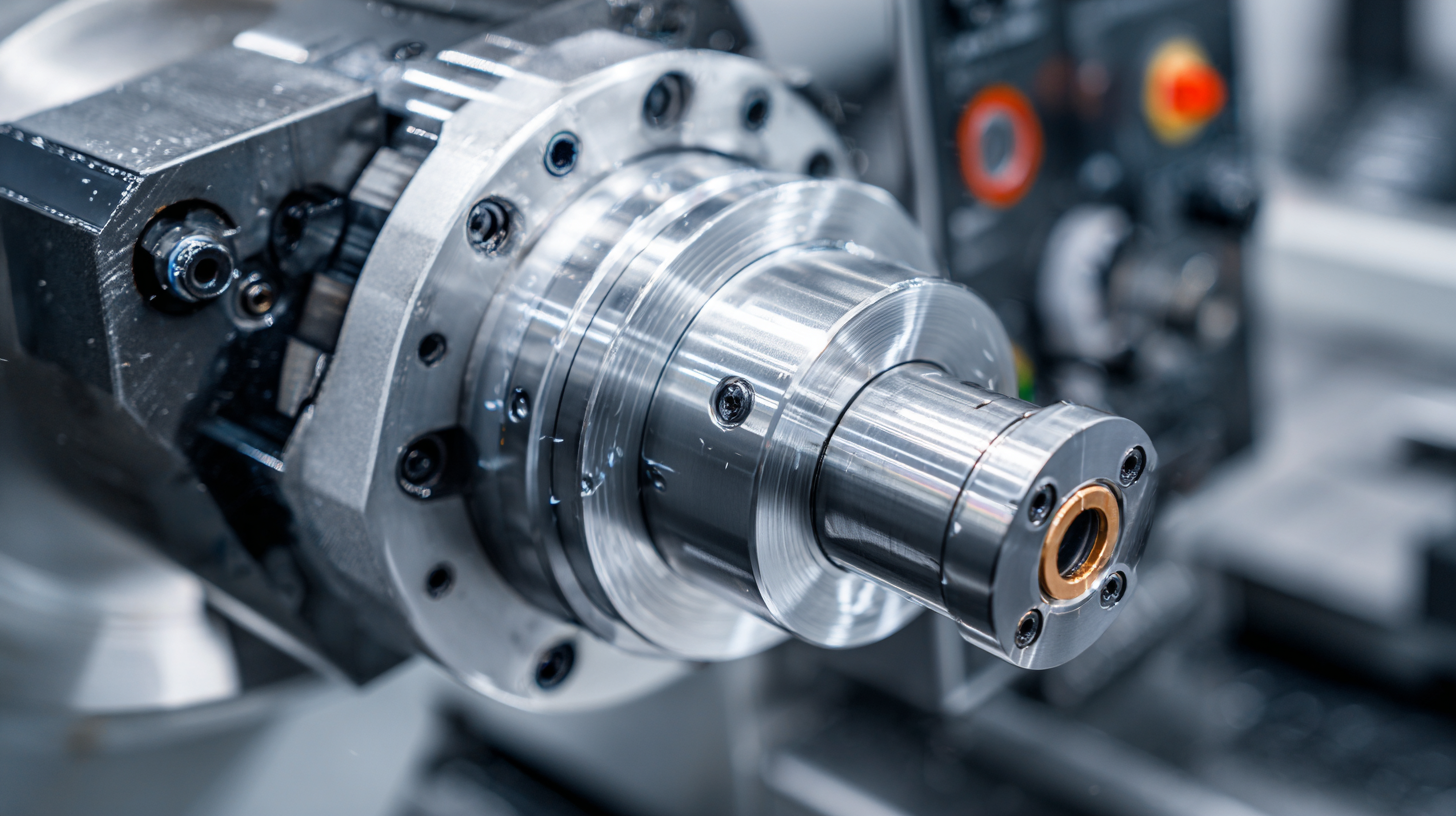

When it comes to machining electrical insulators, having the right tools can make a huge difference in how efficient and precise your work turns out. Honestly, choosing tools that are specifically designed for the tricky materials and details involved in insulator machining is kind of a big deal. Take specialized carbide tools, for example—they tend to wear out less and stay sharper longer than regular tools, which means cleaner cuts and less time messing around changing tools. Plus, if you’re looking to speed things up, investing in high-speed machining tools can help push through production faster, all while keeping tolerances tight and the finish looking smooth.

Another thing to keep in mind is how you set up your tools. Picking ones with the right profile and cutting edge angles really helps with getting good chip removal, which in turn speeds up the cycle time. And if you’re into using the latest tech, CNC machines are a game-changer—they can adjust on the fly based on real-time data, making everything more efficient. On top of that, using software to optimize your toolpaths can really cut down waste and boost your overall output. Bottom line though—picking the right tools and keeping them in top shape is essential if you want to master insulator machining and really improve your efficiency in the process.

Optimizing Machining Settings for Precision and Speed

When it comes to machining electrical insulators, getting your settings just right is really key—you want both precision and speed on your side. Using cutting-edge techniques like laser etching and PFIB etching can make a huge difference, allowing manufacturers to work more efficiently. These methods let you remove material with incredible accuracy, revealing even the tiniest circuit details while keeping the surrounding areas safe from damage. That’s especially crucial when you’re digging into semiconductor failures because you need a delicate touch to find out what really went wrong.

Here at Sichuan D&F Electric Co., Ltd., we truly get how important it is to optimize our machining processes when producing electrical connection parts and insulation components. By tweaking our settings just right, we’re able to ensure our products not only meet top-notch quality standards but also deliver the reliability our customers trust. Plus, adopting these innovative technologies speeds things up and boosts the accuracy of our final products—meaning we can bring even complex designs to life with pinpoint precision. Focusing on these aspects really helps us stay competitive in this fast-changing market landscape.

Implementing Effective Quality Control Measures

When it comes to machining electrical insulators, quality control really has to be a top priority—especially for a trusted company like Sichuan D&F Electric Co., Ltd. To get the best results and keep things running smoothly, putting in place solid quality control measures is a game-changer. One thing I’d definitely recommend is setting up standardized procedures for all your machining steps. That way, you’re more likely to tag consistent quality, and you can avoid those annoying defects that pop up when things go off-course.

Also, don’t forget about continuous training for your team. Keeping everyone up-to-date with the latest techniques and tools means they’re better prepared to tackle any challenges that come their way. And here’s a neat trick: using advanced inspection tech can help monitor the process in real-time. This basically means catching issues early, before they become big problems.

All these little steps not only ramp up productivity but also help make sure that the electrical connection parts coming out of D&F Electric are top-notch. It’s all about reinforcing their dedication to high standards in electrical insulation parts, you know?

Keeping Up with Latest Trends and Technologies in Insulator Machining

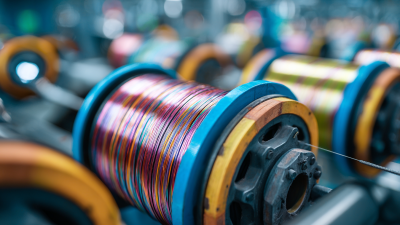

In the fast-changing world of electrical insulator machining, it's pretty important to stay on top of the latest trends and tech if you want to boost efficiency and get more done. One of the coolest advancements lately is the integration of CNC systems—those computer-controlled machines that cut and shape insulators with crazy precision. Not only does this help cut down on mistakes, but it also streamlines the whole process, meaning manufacturers can keep up with rising demand while still delivering consistent, high-quality products. Oh, and with the move towards new materials like composite insulators, there's a whole new ballgame of machining techniques that need to be figured out to make sure they’re tough and reliable.

On top of that, additive manufacturing—better known as 3D printing—is starting to shake things up in insulator production. With 3D printing, companies can now make complicated shapes that used to be a pain to do with traditional machining. This opens up a lot more design options, plus it helps save materials and cut down on waste. Embracing these new techs isn’t just about staying competitive; it’s also about hitting those sustainability goals that are becoming more and more important these days. If businesses invest in the latest machining solutions and keep their teams in the loop about emerging trends, they’ll not only work more efficiently but also position themselves as real leaders in the electrical insulator game.

7 Essential Tips for Mastering Electrical Insulator Machining Efficiency

Maximizing Efficiency and Performance with Custom CNC Machining Insulation Structural Parts

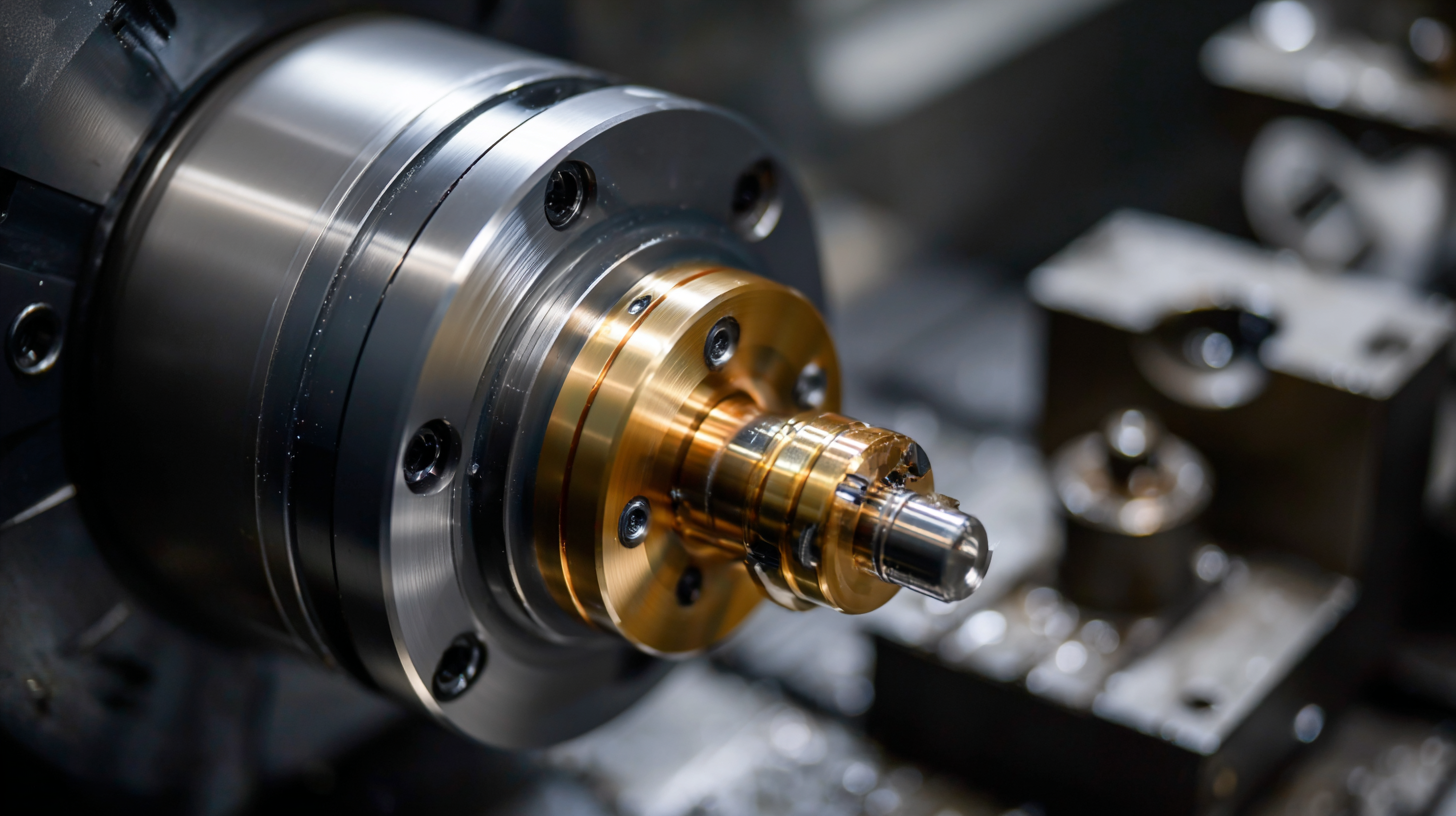

In the ever-evolving manufacturing landscape, the demand for efficient and high-performance components is more critical than ever. Custom CNC machining offers a tailored solution for creating insulation structural parts that meet specific needs in various industries. By utilizing advanced materials like G10, G11, FR4, FR5, EPGC308, UPGM203 (GPO-3), and EPGM sheets, manufacturers can achieve exceptional electrical insulation while ensuring durability and reliability.

These insulation structural parts are designed based on meticulous user specifications, allowing for a high degree of customization. They can be crafted from a wide range of insulation profiles through innovative pultrusion or molding technologies, ensuring that each product aligns perfectly with the client's technical requirements. This level of customization not only maximizes efficiency in production but also enhances the overall performance of the final products, making them well-suited for demanding applications.

By investing in custom CNC machining for insulation structural parts, businesses can optimize their processes, reduce waste, and ultimately improve their bottom line. The combination of high-performance materials and precision engineering offers a unique opportunity to innovate and elevate product standards across various sectors.

FAQS

: The right tools increase efficiency and precision, reduce wear, maintain sharpness longer, and ensure clean cuts, ultimately improving production time.

Specialized carbide tools and high-speed machining tools can significantly enhance machining efficiency by allowing for tighter tolerances and smoother finishes.

CNC systems facilitate precision cutting and shaping, reduce human error, and optimize machining processes, helping manufacturers meet demands with improved consistency and quality.

The correct profile and cutting edge geometry of tools promote optimal chip removal, improving cycle times and overall machining performance.

Toolpath optimization software minimizes waste and maximizes production rates, ensuring that the machining process is as efficient as possible.

Key trends include the integration of CNC systems, the adoption of advanced materials like composite insulators, and the rise of additive manufacturing techniques such as 3D printing.

3D printing allows for the creation of complex geometries that traditional methods cannot achieve, enhancing design flexibility and contributing to material savings.

Keeping abreast of trends enhances efficiency, enables competitiveness, and aligns businesses with sustainability goals, which are increasingly prioritized in the industrial sector.

Investing in modern machining solutions and continuously educating staff about emerging trends can significantly boost efficiency and position businesses as leaders in the market.

Conclusion

Getting a handle on Electrical Insulator Machining is pretty much essential if you want to boost your production and get top-notch results. Honestly, understanding the basics really helps lay a good foundation—like knowing what’s what before diving in. Picking the right tools is a big deal, too, because it affects both how precise you can be and how fast you work. And if you tune your machining settings just right and keep a close eye on quality, you’ll see your output improve a lot without sacrificing standards.

Here at Sichuan D&F Electric Co., Ltd., we’re all about staying updated with the latest trends and tech in insulator machining. As a trusted manufacturer and supplier of electrical connection components and insulation parts, we’re dedicated to using best practices that make our processes more efficient and innovative. That way, we can deliver better products that meet the ever-changing needs of our industry.

Related Posts

-

5 Reasons Why 3240 Epoxy Board is the Best Choice for Your Projects

-

How to Achieve Maximum Energy Efficiency with H Class Insulation Solutions

-

The Ultimate Guide to Understanding Glass Polyester Laminate for Your Projects

-

The Future of China Epoxy Glass Fiber Sheet in Global Markets

-

How to Choose the Right Flexible Busbar Solutions for Your Industrial Needs

-

5 Key Insights on Winding Insulation Class for Optimal Motor Performance