Essential Tips for Understanding Bus Bars in Electrical Systems?

Table of Contents

- Understanding the Definition and Functionality of Bus Bars

- Types of Bus Bars Used in Electrical Systems: A Comprehensive Overview

- Key Specifications and Ratings for Bus Bar Manufacturing

- Material Selection for Bus Bars: Copper vs. Aluminum

- Installation Best Practices for Bus Bars in Electrical Panels

- Safety Standards and Regulations Governing Bus Bar Usage

- Common Issues and Troubleshooting Techniques for Bus Bars

- Comprehensive Guide to Choosing Custom Rigid Copper or Aluminum Bus Bars for Optimal Electrical Performance

- FAQS

- Conclusion

- Related Posts

If you're involved in working with electrical systems, getting a grip on bus bars is pretty important. Like John Smith from PowerTech Innovations puts it, 'Bus bars are basically the backbone of electrical distribution.' They help transfer power efficiently and are crucial for keeping circuits safe and functional.

Typically, bus bars are made from copper or aluminum—they act as the central points where electricity from different sources comes together and gets sent out. When designed and installed correctly, they can really cut down on energy loss. Sadly, a lot of folks don’t pay much attention to them until something goes wrong.

Not knowing enough about bus bars can lead to big failures down the line. So, understanding how they work and their technical details can actually make your systems more reliable. It’s not just about making things run—it’s also about safety. So, yeah, taking a bit of extra time to learn about their design and how they’re used really pays off in the long run.

Understanding the Definition and Functionality of Bus Bars

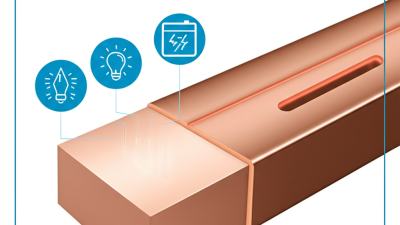

Bus bars are crucial components in electrical systems. They function as conductors that distribute power throughout a system. Typically made of copper or aluminum, bus bars connect various electrical devices. Their design can vary widely, impacting efficiency and safety.

In industrial settings, bus bars can handle high current loads. Reports indicate that poorly designed bus bars may lead to overheating. This poses risks like equipment damage and potential safety hazards. A study highlighted that up to 70% of electrical failures in buildings could trace back to inadequate bus bar installations. It’s essential to ensure proper sizing and layout to mitigate these risks.

Understanding bus bars entails recognizing their role in reducing resistance and improving current flow. Some installations may lack adequate insulation, leading to energy losses. Regular inspections can identify these issues early. Awareness and education about bus bars are key for effective operation within electrical systems. Overlooking these details could have significant consequences.

Understanding Bus Bars in Electrical Systems

Types of Bus Bars Used in Electrical Systems: A Comprehensive Overview

Bus bars play a critical role in electrical systems. They support efficient power distribution and help manage electrical loads. Understanding the types of bus bars available can enhance system design and performance.

There are several types of bus bars used in electrical systems. Common types include copper, aluminum, and insulated bus bars.

Copper bus bars are known for their high conductivity. They are ideal for high-current applications. Aluminum bus bars, while less conductive than copper, are lighter and more cost-effective.

Insulated bus bars provide additional safety. They help prevent accidental contact with energized parts.

Industry reports indicate that the global bus bar market could reach $12 billion by 2027. This suggests growing demand in sectors like renewable energy and electric vehicles. However, designers must consider the thermal management of bus bars.

Overheating can lead to system failures. It is crucial to choose the right material and size for optimal performance. Choosing improperly can lead to inefficiencies and safety hazards.

Key Specifications and Ratings for Bus Bar Manufacturing

Understanding bus bars is crucial for electrical systems. When manufacturing these essential components, various key specifications and ratings must be considered. For example, conductivity is typically measured in percentage IACS. A good standard is around 60% IACS for copper bus bars, which ensures efficient electrical performance.

The dimensions of bus bars influence their current-carrying capacity. A common recommendation is to follow the National Electrical Code (NEC) guidelines. These specify that the minimum width should be 1 inch for every 100A of current. Larger widths can be necessary for ensuring safety and efficiency.

Tip: Always account for thermal expansion when considering bus bar installations. Heat can cause bus bars to expand, potentially leading to mechanical failure. Real-world data suggests that nearly 30% of electrical failures relate to improper installation or specifications. Focus on these details to minimize risks in your electrical systems.

Material Selection for Bus Bars: Copper vs. Aluminum

When it comes to bus bars, the choice of material is crucial. Copper and aluminum are the two main materials used. Copper is known for its excellent conductivity. It is often preferred in applications requiring high current capacity. However, copper is heavier and more expensive than aluminum. It can lead to increased installation costs due to its weight.

On the other hand, aluminum offers a lighter option. It is more cost-effective but has lower conductivity than copper. This means thicker aluminum bars are necessary to carry the same current as copper bars. Additionally, aluminum can be prone to oxidation, which may cause reliability issues. It needs careful treatment and maintenance to ensure longevity.

This material selection should not be taken lightly. Each option has its own advantages and drawbacks. Users need to reflect on their specific requirements. Will you prioritize cost or efficiency? The decision should align with your unique project needs and constraints.

Installation Best Practices for Bus Bars in Electrical Panels

Understanding bus bars in electrical panels requires a focus on installation best practices. Proper installation ensures safety, efficiency, and reliability. According to a report from the International Electrotechnical Commission, improper installation can lead to a 30% increase in electrical losses. Therefore, precision in measurements is critical. Bus bars should be firmly mounted to avoid vibrations that may lead to fatigue over time.

Alignment is essential during installation. Misaligned bus bars can result in poor connectivity and localized heating. The National Fire Protection Association highlights that approximately 25% of electrical fires are related to improper connections. Ensuring that each connection is snug and secure will mitigate this risk. Use torque specifications provided by industry standards to achieve the correct attachment.

Moreover, consider using thermal monitoring tools to assess heat distribution across bus bars. They can help identify hotspots. Regular maintenance checks are vital as well. Routine inspections can catch potential issues before they escalate. This proactive approach could prevent unexpected downtime, ensuring optimal operation in the long run. Emphasizing these best practices can greatly enhance the performance and longevity of electrical systems.

Safety Standards and Regulations Governing Bus Bar Usage

Understanding bus bars is crucial for safety in electrical systems. These components distribute power and connect various circuits. However, safety standards are paramount. Organizations such as the National Electrical Manufacturers Association (NEMA) provide guidelines to ensure compliance. Following these standards can prevent overheating and potential failures.

When working with bus bars, always wear appropriate personal protective equipment. This includes gloves and safety goggles. Understand the specific regulations applicable to your region. Sometimes, these rules vary widely. For example, using insulated bus bars can reduce accident risks.

It's essential to regularly inspect bus bars for wear and tear. Look for signs of corrosion or poor connections. These can lead to serious issues. It’s easy to overlook maintenance in busy settings. Yet, ignoring these details can result in costly repairs. Be proactive and attentive to safety standards. They are there for a reason.

Common Issues and Troubleshooting Techniques for Bus Bars

Bus bars play a crucial role in electrical systems. They distribute power from generators and transformers to various circuits. However, issues can arise that affect performance. Common problems include overheating, corrosion, and poor connections. Overheating can occur due to overloading or inadequate ventilation. A report indicated that 30% of electrical failures are linked to poor thermal management.

Corrosion is another significant issue for bus bars. Environmental conditions can lead to oxidation. This weakens the metal and reduces conductivity. Regular inspections can help identify these vulnerabilities. In one study, almost 25% of bus bars had signs of corrosion that went unnoticed. Such problems can escalate if not addressed promptly.

Troubleshooting techniques are vital for maintaining bus bars effectively. Checking electrical connections regularly can prevent failures. Visual inspections can reveal physical damage. Using thermal cameras can detect hotspots before they become critical issues. Many technicians overlook these methods, leading to avoidable outages. Keeping accurate records of maintenance practices allows for better forecasting of potential issues.

Comprehensive Guide to Choosing Custom Rigid Copper or Aluminum Bus Bars for Optimal Electrical Performance

When selecting custom rigid copper or aluminum bus bars, understanding the core characteristics that influence electrical performance is crucial. According to industry reports, the effectiveness of a bus bar directly correlates with its material composition and design features. Copper bus bars are widely recognized for their superior electrical conductivity, which can be as high as 97% for pure copper, making them ideal for heavy current applications. Conversely, aluminum bus bars, while having slightly lower conductivity, offer a lightweight alternative with sufficient strength for many applications.

Precision in manufacturing is equally important; hence, the CNC machining process has become a standard in the production of bus bars. This method allows for intricate designs that can accommodate various cross-sectional shapes, such as rectangular or rounded profiles. Rounded bus bars are particularly advantageous in preventing point discharge, which can lead to energy loss and safety hazards. A comprehensive understanding of these factors ensures that users can select the most suitable bus bars for their specific requirements, optimizing overall electrical performance while maintaining safety and efficiency.

Moreover, factors such as surface finish and additional treatments can further enhance the longevity and conductivity of bus bars. Applying coatings or finishes can reduce oxidation, which is crucial for maintaining the performance of bus bars in varying environmental conditions. As electrical systems continue to evolve, the demand for high-quality, custom bus bars capable of meeting precise technical specifications remains critical in achieving optimal electrical performance in modern applications.

FAQS

: The product aims to enhance daily living. It offers convenience and better organization.

Use it as directed. Follow the instructions for best results and safety.

Yes, it can be used outside. Just ensure it is protected from harsh weather.

It is made from durable materials. These materials ensure longevity and reliability in use.

A warranty may be offered. Please check the product details for specific warranty information.

Cleaning is simple. Use a damp cloth and mild soap to wipe off dirt.

Some users reported minor defects. Regular inspections can help identify these issues early.

Returns are allowed within a limited time. Ensure the product is unused and in original packaging.

Look for contact details on the packaging. Email or phone support is usually available.

Several shipping methods may be offered. Delivery times can vary based on location and choice.

Conclusion

Bus bars are critical components in electrical systems, serving as conductive pathways that connect various electrical devices and distribute power effectively. Understanding their definition and functionality is essential for anyone working with electrical installations. There are several types of bus bars, each designed for specific applications, and selecting the right material—whether copper or aluminum—is crucial for performance and durability.

When manufacturing bus bars, it's important to consider key specifications and ratings that dictate their suitability for different environments. Installation best practices should be followed to ensure safety and efficiency, while adhering to established safety standards and regulations is vital to prevent hazards. Additionally, common issues such as overheating or corrosion can arise, requiring effective troubleshooting techniques to maintain optimal performance and safety in electrical panels.

Related Posts

-

How to Choose the Right Bus Bars for Your Electrical System Needs

-

How to Choose the Right Metal Bus Bar for Your Electrical Needs

-

What is a Plated Copper Bus Bar and Its Applications?

-

Top 10 Benefits of Low Inductance Busbars for Efficient Power Distribution

-

Unlocking the Advantages of Bare Copper Strip in Electrical Applications for Energy Efficiency

-

Top 2025 Trends in Copper Busbar Technology and Applications