The Future of China Epoxy Glass Fiber Sheet in Global Markets

Table of Contents

- The Rise of Epoxy Glass Fiber Sheets in China's Manufacturing Sector

- Global Market Demand Trends for Epoxy Glass Fiber Sheets by 2025

- Comparative Analysis: China's Epoxy Glass Fiber Sheet Prices vs. Global Competitors

- Technological Innovations Driving the Epoxy Glass Fiber Industry in China

- Sustainability in Production: Environmental Impact of Epoxy Glass Fiber Sheets in China

- Future Market Opportunities: Key Industries Adopting Epoxy Glass Fiber Solutions

- FAQS

- Conclusion

- Related Posts

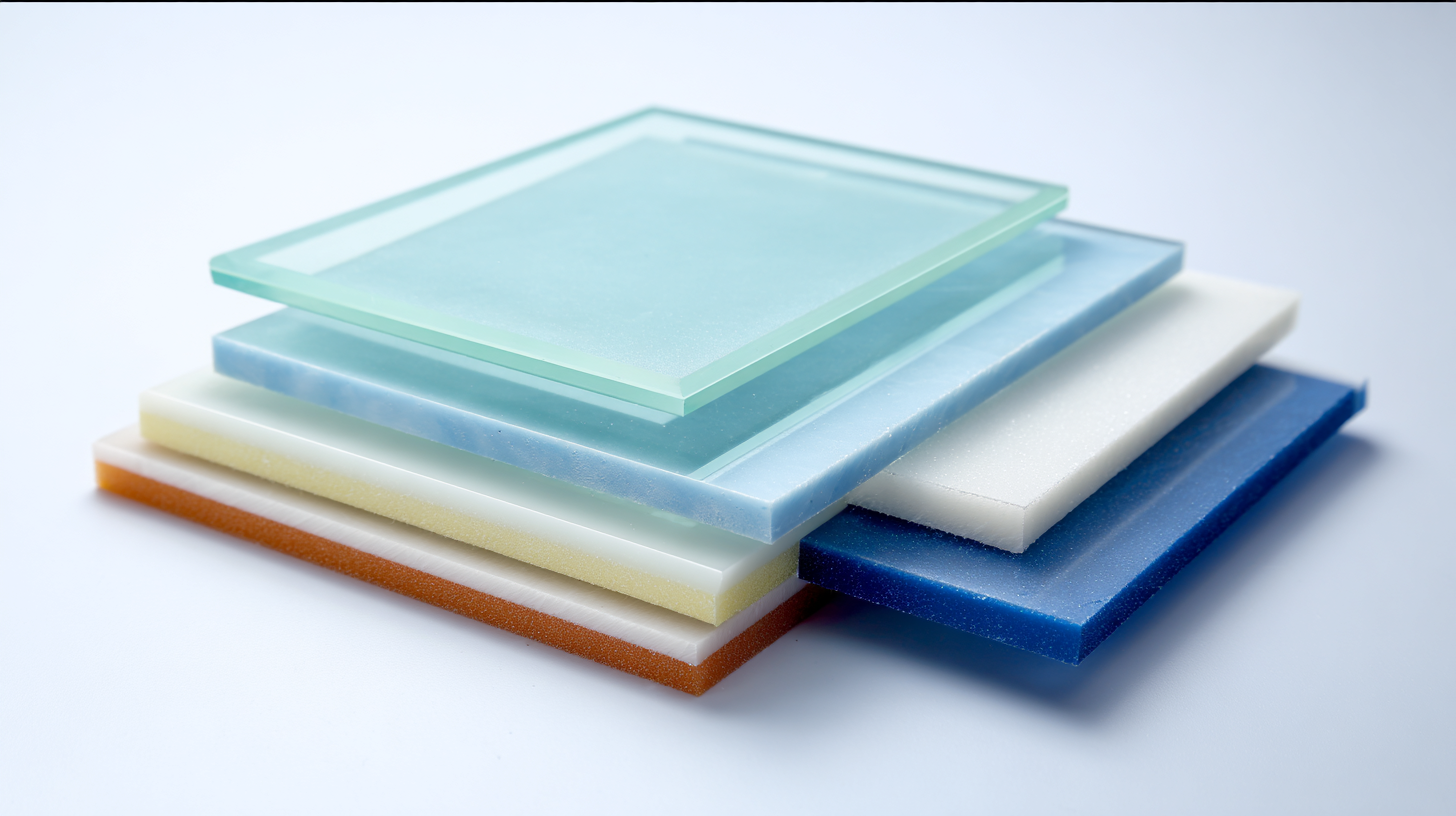

You know, as the world keeps cranking up its need for advanced materials—especially in electronics and electrical stuff—the importance of China Epoxy Glass Fiber Sheets is really on the rise. I read recently that the global market for these sheets is expected to hit around 6.5 billion USD by 2027. That's quite a chunk! And it's growing at an annual rate of about 5.4% from 2020 onwards, so the demand’s definitely not slowing down.

On the scene, Sichuan D&F Electric Co., Ltd. has been a pretty big name since 2005 when they started out. They're based in Deyang’s Jinshan Industrial Park in Sichuan, and they’ve stuck to their guns—making top-notch electrical connection parts and insulation components. Their goal? To keep up with what industries around the world keep needing.

In this blog, I’ll dive into what the future might hold for China Epoxy Glass Fiber Sheets in the global market—talking about the cool innovations, new uses, and how the industry is changing as a whole. It’s pretty exciting stuff!

The Rise of Epoxy Glass Fiber Sheets in China's Manufacturing Sector

You know, China's manufacturing scene is really going through a big change right now, mainly because of the rise in epoxy glass fiber sheets. It’s not just about producing more stuff locally—although that’s a big part of it—it's also a clear sign that industries everywhere are craving lighter yet super strong materials. And get this: experts are saying that the global market for Fiber Reinforced Polymer (FRP) composites is gonna jump from around $98 billion in 2024 all the way up to nearly $190 billion by 2032. That’s a huge deal and shows how excited everyone is about materials that boost product performance.

As Chinese manufacturers start to really embrace these epoxy glass fiber sheets, they’re basically jumping on this worldwide growth train. And it’s not just that—related markets like high modulus carbon fiber are also expected to grow from about $4.2 billion in 2024 to around $7.5 billion by 2033. Thanks to advanced manufacturing methods and a stronger push towards sustainability, China is positioning itself as a major player in the FRP scene. They’re not just keeping up—they’re innovating, meeting top-notch international standards, and pushing to be more productive and eco-friendly all at the same time.

Global Market Demand Trends for Epoxy Glass Fiber Sheets by 2025

Hey, so it looks like the worldwide market for epoxy glass fiber sheets is really set to grow a lot as we get closer to 2025. Thanks to new manufacturing tech and the rising demand from tons of different industries, these materials are turning into key players—think automotive, aerospace, building, and more.

Companies are on the hunt for materials that are lightweight but tough enough to handle whatever's thrown at them, and epoxy glass fiber sheets fit the bill perfectly. They’re super strong, resistant to environmental wear and tear, and just generally reliable for all kinds of demanding applications.

It’s also clear that there’s a shift towards custom solutions—stuff tailored to specific industry needs. As these industries keep changing and pushing forward, the need for specialized materials that can survive extreme conditions without breaking is growing.

And it’s not just about innovation anymore; sustainability is taking center stage too. Manufacturers are now looking to develop more eco-friendly options within the epoxy glass fiber sheet space. Over the next few years, we can probably expect to see more production capacity and wider use of these materials, really cementing their spot in the global market.

Comparative Analysis: China's Epoxy Glass Fiber Sheet Prices vs. Global Competitors

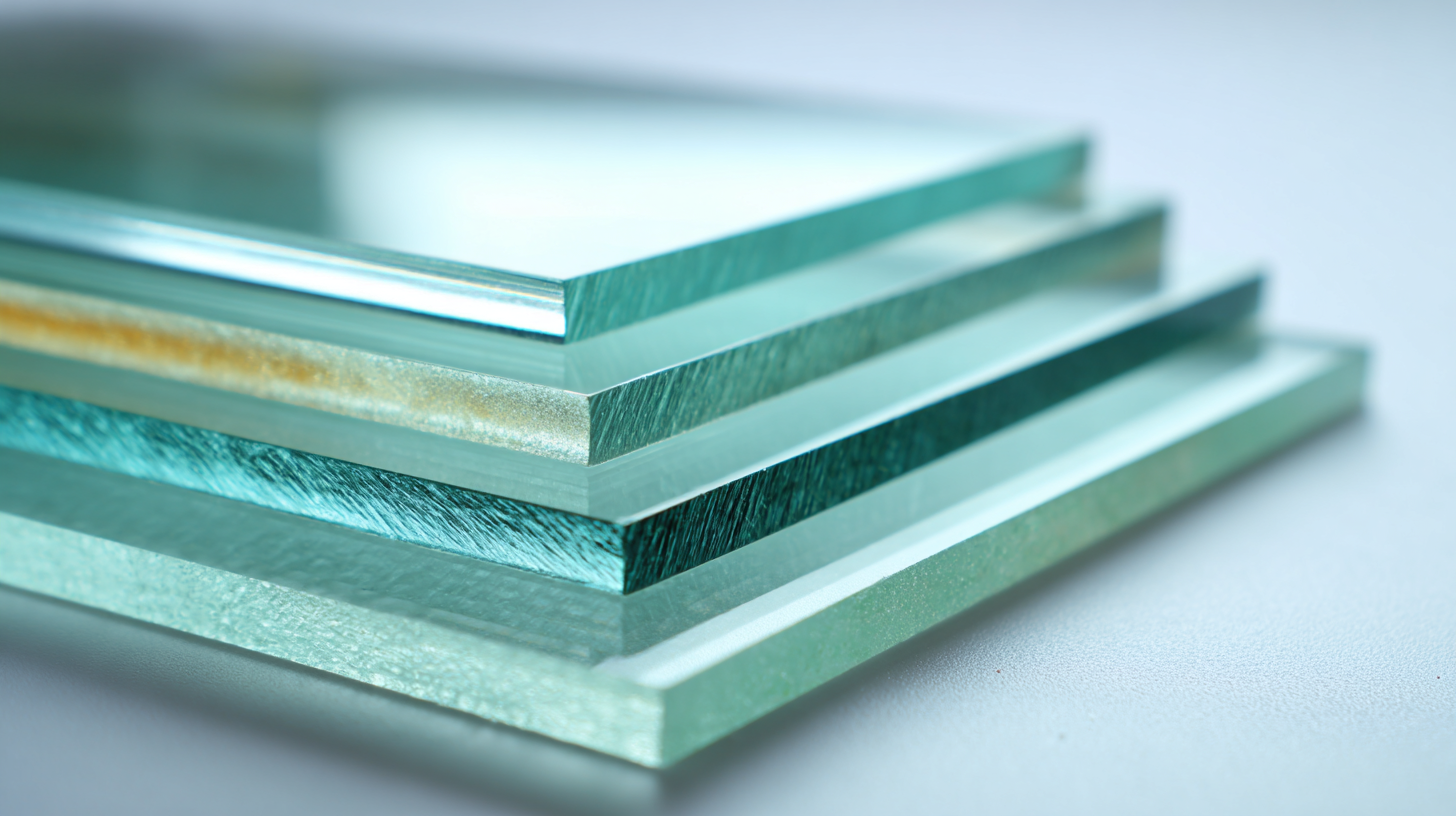

Lately, the epoxy glass fiber sheet market has really been growing, and China is now pretty much at the forefront. I read in a report by MarketsandMarkets that by 2026, the global market could hit around USD 2.7 billion, growing at roughly 6.5% annually since 2021. A big reason for this boom? China’s competitive pricing. Local manufacturers like Jushi Group and Jiangsu Huatai are able to keep costs lower than international players, thanks to cheaper production and support from the government.

If you look at the prices, Chinese epoxy glass fiber sheets typically go for somewhere between USD 3 and USD 6 per square meter, which is a lot more affordable compared to North America and Europe — where prices can actually hit USD 10 to USD 15 per square meter. That’s mainly because China’s huge production facilities give them economies of scale, which helps cut down costs. Plus, their continuous push to improve production tech makes these sheets a pretty attractive and cost-effective option for industries like automotive, electronics, and renewable energy—especially since high-quality materials are a must for innovation and reliable performance.

Technological Innovations Driving the Epoxy Glass Fiber Industry in China

Hey, have you heard about what's happening in China's epoxy glass fiber scene? It's pretty exciting — there’s a real shift happening thanks to some pretty cutting-edge tech innovations. I came across this report by MarketsandMarkets that says the global epoxy resin market is set to jump from around $7.28 billion in 2021 to over $11 billion by 2026. A lot of it is driven by new ways of making these materials and figuring out better formulations. Chinese companies are really leading the charge here, tweaking processing techniques and coming up with new blends that make epoxy glass fiber sheets stronger and last longer.

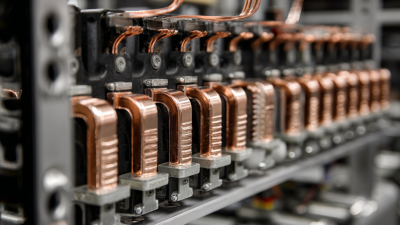

One of the coolest developments? Automated manufacturing. Not only does it speed things up, but it also cuts down on waste, which is a huge plus. There was a study from Research and Markets pointing out that if Chinese firms keep pushing automation in fiber optics and composite materials, they could see production jumps of over 30% by 2025. That kind of innovation is key if they want to stay competitive globally — because, honestly, quality and cost are everything.

So, if you're a manufacturer thinking about jumping into epoxy glass fiber production, it’s really worth keeping an eye on new tech trends and market shifts. Partnering up with research centers might give you some awesome insights and help push your innovation game. And don’t forget about sustainability — using eco-friendly materials and practices can not only keep you compliant with regulations but also give your brand a bit of an edge in this eco-conscious world we’re living in.

Sustainability in Production: Environmental Impact of Epoxy Glass Fiber Sheets in China

In recent years, China’s production of epoxy glass fiber sheets has gone through quite a bit of change. You know, there’s been a real shift toward more eco-friendly practices, which is pretty cool. With global markets pretty much demanding greener materials these days, manufacturers in China are really trying to cut down their carbon footprint and improve how they make things. It’s not just about following trends — they’re adopting greener technology and using more sustainable materials. That way, not only do they make environmentally friendly epoxy glass fiber sheets, but they also cater to the growing demands of consumers worldwide who care more and more about sustainability.

A big part of this is making their processes more resource-efficient and waste-conscious. Many companies are now recycling scrap material and investing in energy-saving machinery to help lower emissions. Plus, there's a rising interest in switching to bio-based epoxy resins instead of the traditional petroleum-derived ones. This approach supports a circular economy and lines up nicely with global sustainability goals, putting China in a good position as a leader in green materials. Looking ahead, the whole game will depend on how well the industry manages to balance really high production needs with being kind to the environment — it’s all about finding that sweet spot.

The Future of China Epoxy Glass Fiber Sheet in Global Markets - Sustainability in Production: Environmental Impact of Epoxy Glass Fiber Sheets in China

| Year | Production Volume (tons) | CO2 Emissions (tons) | Recycled Materials (% of total) | Market Growth Rate (%) | Sustainability Initiatives |

|---|---|---|---|---|---|

| 2020 | 150,000 | 50,000 | 10 | 5 | Reduced Toxic Emissions |

| 2021 | 160,000 | 48,000 | 12 | 6 | Energy Efficiency Programs |

| 2022 | 170,000 | 45,000 | 15 | 7 | Waste Reduction Strategies |

| 2023 | 180,000 | 43,000 | 20 | 8 | Circular Economy Projects |

Future Market Opportunities: Key Industries Adopting Epoxy Glass Fiber Solutions

You know, the aerospace and defense industries in the US and the UK are changing pretty fast right now. That opens up some pretty exciting opportunities for epoxy glass fiber solutions. These sectors really rely on high-performance materials for their printed circuit boards (PCBs), and that’s a big deal because it directly affects how much the market grows. For example, in 2023, the worldwide PCB market was worth around $69.69 billion. And experts expect it to jump to about $113.49 billion by 2032. As technology gets more advanced in aerospace and defense, there’s a growing need for materials that are tough, lightweight, and flexible — and epoxy glass fiber sheets are crucial for that.

On top of that, the epoxy resin market itself is set to grow. It’s currently valued at roughly $135 billion in 2024 and could hit nearly $213.7 billion by 2032, which is an annual growth rate of about 5.9%. As these industries keep adopting epoxy glass fiber solutions, companies like Sichuan D&F Electric are in a great spot to supply key electrical parts and insulation components. All in all, this alignment between emerging market needs and new products shows a bigger picture — a shift towards more sustainable and innovative materials that really cater to these critical fields.

FAQS

: Epoxy glass fiber sheets are advanced composite materials made from glass fibers embedded in an epoxy resin, known for their high strength, lightweight, and resistance to environmental factors.

The demand is rising due to the need for lightweight and high-strength materials across various industries, as well as a transformation in China's manufacturing capabilities and a response to global market trends.

Key industries benefiting from these materials include automotive, aerospace, construction, and other sectors that require durable and reliable components.

The global market for epoxy glass fiber sheets is expected to grow significantly, driven by advancements in manufacturing technologies and an increasing demand for these materials in various applications.

Their high strength, lightweight nature, and resistance to environmental factors make epoxy glass fiber sheets ideal for applications that require performance and reliability.

Yes, there is a growing preference for custom solutions tailored to specific industry needs, reflecting an evolution in requirements for specialized materials.

Manufacturers are increasingly focused on developing eco-friendly options within the epoxy glass fiber sheet segment, responding to the demand for sustainable materials in manufacturing.

The global FRP composites market is projected to increase from $98.12 billion in 2024 to $189.80 billion by 2032, indicating a significant interest in high-performance materials.

Advancements in manufacturing techniques are leading to improved production capabilities and a greater application scope for epoxy glass fiber sheets, solidifying their role in the marketplace.

Future trends include expanded production capabilities, an increase in application scope, and a continued focus on sustainability and innovation in material development.

Conclusion

Hey, did you get a chance to read that blog about 'The Future of China Epoxy Glass Fiber Sheets in Global Markets'? It's pretty interesting — it talks about how these epoxy glass fiber sheets are really gaining ground in China's manufacturing scene. And honestly, they're becoming super important across a bunch of different industries. Looking ahead to 2025, the global demand for these materials is expected to stay strong. The article also digs into how China's pricing stacks up against other countries, making it clear they're pretty competitive. One of the coolest parts is how tech innovations are pushing the Chinese epoxy glass fiber industry forward — making production more efficient and opening up more ways to use these materials. Plus, there’s a focus on sustainability, which is great because it shows they’re thinking about the environmental impact. As more industries jump on board, it looks like China’s epoxy glass fiber sheets are set to play a pretty big role in the global market — definitely an exciting future!

Oh, and by the way, Sichuan D&F Electric Co., Ltd., has been around since 2005. They’re a solid name when it comes to manufacturing and supplying electrical insulation parts. They really help push the industry forward by using the latest in epoxy glass fiber tech to keep up with what their clients need. Pretty impressive, right?

Related Posts

-

How to Choose the Right Flexible Busbar Solutions for Your Industrial Needs

-

Exploring the Unique Properties and Applications of Best Nomex T410 Film: A Comprehensive Guide for Buyers

-

Solutions for Enhancing Electrical Efficiency with Silver Plated Copper Bus Bars

-

The Ultimate Checklist to Choosing the Best Copper Bus Bar for Global Procurement

-

Essential Checklist for Global Buyers: Navigating Gpo3 Machining Procurement

-

How to Choose the Best Tin Plated Copper Bus Bar for Your Electrical Needs