The Future of High Temperature Insulation Board in Sustainable Construction

Table of Contents

- Exploring the Role of High Temperature Insulation Boards in Energy-Efficient Buildings

- Advancements in Material Science for Sustainable High Temperature Insulation Solutions

- The Environmental Impact of High Temperature Insulation Boards in Construction

- Cost-Benefit Analysis of Using High Temperature Insulation in Green Building Projects

- Case Studies: Successful Implementations of High Temperature Insulation Boards

- Enhancing Electrical Efficiency: Insights from 2023 Market Reports on High-Quality Laminated Bus Bars in China

- FAQS

- Conclusion

- Related Posts

You know, these days, the construction world is really starting to pay more attention to sustainability. One of the coolest parts about it is using innovative materials like High Temperature Insulation Boards. Honestly, if you look at market trends, it’s pretty clear that the global market for high-temp insulation is set to grow a lot — mainly because everyone’s craving energy-efficient solutions in different building projects. Companies like Sichuan D&F Electric Co., Ltd., which kickstarted their journey back in 2005, are really stepping up by making top-notch electrical connectors and insulation parts. They’ve become quite a key player in this rapidly changing scene. As architects and builders look for ways to boost energy efficiency without compromising on strength and safety, using these High Temp Insulation Boards is going to be a game-changer. Incorporating these advanced materials isn’t just about keeping up; it’s about tackling climate change head-on while staying aligned with the industry's move toward greener, more sustainable construction practices.

Exploring the Role of High Temperature Insulation Boards in Energy-Efficient Buildings

High temperature insulation boards, or HTIBs for short, are pretty essential when it comes to making buildings more energy-efficient. They're specially designed to handle really high temperatures, which makes them perfect for industrial sites, commercial spaces, or even homes that need good thermal regulation.

Basically, they help keep the heat in or out, reducing the strain on your heating and cooling systems. That means not only lower energy bills but also less wear and tear on your equipment—saving you money in the long run.

On the whole, as we try to build greener and more sustainable structures, using HTIBs fits right into that picture. More architects and builders are leaning towards eco-friendly materials, and these insulation boards score well when it comes to meeting strict energy standards and green building certifications. Plus, they’re super durable, which means they last longer and don’t need replacing as often—helping to cut down on waste.

All in all, adding high temp insulation boards can really make a difference in reducing the environmental impact of new buildings, so they’re pretty much a no-brainer for a more sustainable future.

Advancements in Material Science for Sustainable High Temperature Insulation Solutions

You know, advancements in material science are really transforming how we develop high-temperature insulation boards, making them a key part of more eco-friendly building practices. Recently, there's been a lot of exciting work on creating lightweight yet durable materials that can handle extreme heat—without piling up environmental issues. For example, some researchers are experimenting with bio-based composites and recycled stuff that not only resist heat well but also cut down on the need for traditional manufacturing methods, which are usually energy-hungry.

And then there's nanotechnology, which is kinda revolutionizing the game. By adding tiny nanoscale ingredients, manufacturers can boost the thermal performance and strength of these boards. This means they can be made thinner, more efficient, and perfect for tight spaces—like in industrial furnaces or energy-saving buildings. Honestly, as these innovations keep coming, the outlook for high-temperature insulation is pretty bright. It feels like we’re heading toward smarter, greener construction techniques that save energy and are better for the planet.

The Environmental Impact of High Temperature Insulation Boards in Construction

When we talk about high-temperature insulation boards, their impact on the environment is becoming more and more important, especially as we're all looking toward more sustainable building practices. These boards are pretty vital when it comes to making buildings more energy-efficient—they help cut down energy use and, in turn, reduce greenhouse gas emissions. Essentially, by insulating structures well against extreme temperatures, these boards help us rely less on heating and cooling systems, which not only saves money but also does a better job at protecting our planet.

Sichuan D&F Electric Co., Ltd. is really leading the charge in this area. They've been around since 2005 and focus on making top-quality electrical insulation parts. What's cool is that they’re dedicated to creating solutions that are safe, reliable, and aligned with global sustainability goals. They use eco-friendly materials and more environmentally conscious manufacturing processes for their high-temperature insulation boards. All of this adds up to helping the construction industry move toward greener, more responsible practices—making our building environments better for everyone.

Cost-Benefit Analysis of Using High Temperature Insulation in Green Building Projects

Lately, there's been a real buzz around sustainability in construction, and one of the big trends is the growing use of high-temperature insulation boards, especially in green building projects. Did you know that a recent report from the International Energy Agency pointed out that almost 40% of the world's energy is used by buildings? That really highlights just how crucial energy-efficient materials are these days. These insulation boards aren’t just about keeping things warm or cool—they actually save a lot of money over time, too. In fact, the U.S. Department of Energy found that using advanced insulation can cut heating and cooling costs by up to 30%, which is pretty significant for both developers and homeowners trying to save a buck.

And if you look at the bigger picture—like the whole lifecycle costs—these boards really shine. A detailed study by the National Institute of Standards and Technology shows that even though they might cost a bit more upfront compared to traditional options, the long-term savings on energy, maintenance, and even potential tax breaks make them well worth it. Plus, by reducing our reliance on fossil fuels, they help move us toward a more sustainable future—so, in a way, they’re a win-win for the environment and your wallet. If you're building with care for the planet, these materials are definitely worth considering.

The Future of High Temperature Insulation Board in Sustainable Construction

This chart illustrates the cost-benefit analysis of using high temperature insulation in green building projects. The data represents the estimated costs associated with materials and installation, compared to the benefits achieved through energy savings, longevity, and positive environmental impact.

Case Studies: Successful Implementations of High Temperature Insulation Boards

High-temperature insulation boards, or HTIBs for short, are really starting to stand out as essential parts of sustainable building practices these days. They’re especially making waves in industries like manufacturing and energy production. If you look at some real-world examples, it’s clear these boards are making a difference—boosting energy efficiency and helping with thermal management. For example, according to a report from ASHRAE, adding HTIBs can slash energy use by up to 30% in high-temperature settings. That’s a big deal because it lowers costs and even shrinks the carbon footprint—totally in line with today’s push for sustainability.

One cool example is a project at a petrochemical plant in Texas. They used these boards to keep processes running at the right temperatures, which cut down on heat loss quite a bit. Industry reports from the Insulation Contractors Association point out that facilities using top-notch HTIBs saw their investment pay off in about two years, thanks to lower energy bills. Plus, these boards are built to last, meaning less money spent on maintenance. Overall, it’s pretty clear that HTIBs are not just effective—they’re also a smart, eco-friendly choice for high-temperature applications.

Enhancing Electrical Efficiency: Insights from 2023 Market Reports on High-Quality Laminated Bus Bars in China

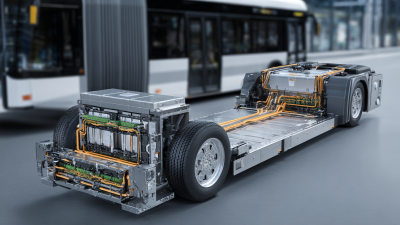

In recent years, the importance of electrical efficiency has become increasingly paramount, especially within the rapidly evolving landscape of the Chinese market. The 2023 market reports highlight a notable focus on high-quality laminated bus bars, which are integral to enhancing electrical performance in various applications. As an engineered component, the laminated bus bar—or composite bus bar as it is also known—consists of precisely arranged copper conductive layers interspersed with thin dielectric materials. This design effectively minimizes energy loss while maximizing conductivity, making these bus bars a crucial element in modern electrical systems.

Laminated bus bars are recognized for their low inductance, which translates to superior performance in high-frequency applications. Their construction mitigates the issues commonly associated with traditional bus bars, such as heat generation and electromagnetic interference. As industries move towards more compact and efficient designs, the demand for laminated bus bars is anticipated to rise, particularly as they offer a streamlined solution for enhanced electrical efficiency. With continuous advancements in manufacturing techniques, the quality of these bus bars is expected to improve further, providing promising insights for the future of electrical engineering in China and beyond.

FAQS

: HTIBs are advanced insulation materials designed to withstand extreme heat conditions while minimizing environmental impact. They are crucial for sustainable construction as they enhance thermal efficiency and help reduce energy consumption in buildings.

Advancements in material science are leading to the creation of lightweight and durable high-temperature insulation materials, such as bio-based composites and recycled materials, which improve thermal resistance and reduce environmental impact.

Nanotechnology enhances the performance of insulation boards by incorporating nanoscale additives, improving thermal properties and mechanical strength, which allows for thinner and more efficient insulation solutions.

Implementing high temperature insulation boards can reduce heating and cooling costs by up to 30%, offering significant financial benefits for project developers and homeowners over time.

While the initial investment in high temperature insulation boards may be higher, long-term savings in energy, maintenance, and potential tax incentives make them a financially attractive option, ultimately providing a strong return on investment.

One notable case study is a petrochemical facility in Texas, where the use of HTIBs resulted in optimal process temperature maintenance and a significant decrease in heat loss, leading to a return on investment within two years due to lower energy consumption.

HTIBs help reduce operational costs and carbon footprints in high-temperature processing environments, aligning with sustainability goals by minimizing reliance on fossil fuels and promoting energy efficiency.

The longevity and durability of HTIBs contribute to reduced maintenance costs, making them an effective sustainable solution in high-temperature applications, alongside financial savings from energy efficiency.

Conclusion

The article titled "The Future of High Temperature Insulation Board in Sustainable Construction" takes a pretty deep dive into how important High Temperature Insulation Boards, or HTIB, are when it comes to making buildings more energy-efficient. As material science keeps evolving, these insulation options are getting better not just in performance but also in being eco-friendly. And honestly, HTIB is becoming a key player in the ongoing battle to cut down energy loss in construction projects. The piece also looks into their environmental impact and offers a cost-benefit rundown, pointing out the clear economic perks of using HTIB in green building initiatives.

They even share some real-world examples — case studies that show how well these boards work in actual applications. Plus, with Sichuan D&F Electric Co., Ltd. pushing forward to produce reliable electrical insulation parts, they’re definitely on the right track to help meet the rising demand for more sustainable building practices that include HTIB. All in all, it’s a pretty interesting look at how this technology might shape the future of eco-friendly construction.

Related Posts

-

How to Achieve Maximum Energy Efficiency with H Class Insulation Solutions

-

7 Essential Tips for Choosing the Right H Class Insulation for Your Industrial Needs

-

Identifying Challenges with Electric Vehicle Busbar Innovations

-

Exploring the Unique Properties and Applications of Best Nomex T410 Film: A Comprehensive Guide for Buyers

-

The Ultimate Guide to Understanding Glass Polyester Laminate for Your Projects

-

5 Reasons Why 3240 Epoxy Board is the Best Choice for Your Projects