The Future of Innovation in the Copper Aluminum Busbar Market

Table of Contents

- Challenges of Current Copper Aluminum Busbar Designs

- Impact of Technological Advancements on Busbar Efficiency

- Sustainability Issues in Copper Aluminum Busbar Production

- Market Trends Influencing Innovation Strategies

- Case Studies of Successful Innovations in the Industry

- Future Prospects for Copper Aluminum Busbar Applications

- The Essential Guide to Choosing Between Custom Rigid Copper and Aluminum Bus Bars for Your Application

- FAQS

- Conclusion

- Related Posts

The Copper Aluminum Busbar Market is really gearing up for some serious growth, and honestly, it makes sense with the global push for better, more efficient electrical systems. According to a report by MarketsandMarkets, this market might hit around USD 25 billion by 2025. The excitement is mainly around copper and aluminum busbars, which are favored because they conduct electricity so well and don’t break the bank — pretty much a win-win. One company that's been around the block since 2005 is Sichuan D&F Electric Co., Ltd., based in Jinshan Industrial Park in Deyang, Sichuan. They're all about making reliable electrical connection parts and insulation components that you can count on. And with the industry changing so fast, staying ahead means embracing new manufacturing tech and fresh materials. This guide’s here to give you a peek into what’s next for the Copper Aluminum Busbar Market—think innovative trends, cool new tech, and some smart strategies to help everyone keep up in this fast-moving scene.

Challenges of Current Copper Aluminum Busbar Designs

Right now, the designs for copper-aluminum busbars are facing quite a few hurdles that can affect how well they work and how long they last. One of the biggest issues is corrosion happening at the spots where copper and aluminum are joined together. That dissimilar metal connection doesn't just reduce the conductivity – it also makes failure more likely as time goes on. Engineers really need to come up with clever solutions to prevent galvanic corrosion and keep these systems reliable, even in tough environmental conditions.

Then there's the whole weight and structural strength thing. Copper is super conductive, no doubt about it, but it's also pretty heavy compared to aluminum. That heavier weight can make installing these busbars more of a hassle, and it puts extra load on the support structures down the line. To tackle this, people are exploring hybrid designs—mixing lightweight materials with copper and aluminum—to get the best of both worlds: good performance and durability. Fixing these issues is key if we want busbar systems to be more efficient and reliable in the future.

Impact of Technological Advancements on Busbar Efficiency

You know, the way technology's moving forward is really shaking up the copper-aluminum busbar market. It's making things more efficient and boosting performance across all kinds of industries. As manufacturers keep pushing boundaries, we're seeing some pretty cool stuff—like smart busbars that come with IoT features. These let companies monitor things in real-time and catch potential issues before they turn into big problems. The best part? Less downtime, and better energy use, which is great for sustainability goals we all care about.

If you're looking to boost busbar efficiency, a few simple tips can help. Regular check-ups and swapping out old materials for newer, more conductive alloys can make a noticeable difference. Plus, bringing automation into manufacturing not only sharpens precision but also cuts down on waste. And honestly, investing in training your team to get comfortable with these new tech tools can really pay off — it makes everything run smoother and boosts overall productivity.

On top of that, using data analytics can give you a clear picture of how your systems are performing, helping you decide when upgrades or maintenance are really needed. Taking a proactive stance like this encourages innovation and keeps companies competitive. All in all, embracing these cutting-edge busbar technologies isn't just smart—it's essential for staying ahead in this rapidly changing market.

Sustainability Issues in Copper Aluminum Busbar Production

When it comes to manufacturing copper-aluminum busbars nowadays, their sustainability really matters—a topic everyone's starting to pay more attention to. As industries push for greener practices, it's crucial to look at the environmental impact of how these busbars are made. Both copper and aluminum are pretty energy-hungry to mine and process, which makes us wonder if their supply chains are really sustainable. One of the best ways to tackle this is by boosting recycling efforts — recycled materials take less energy to produce and generate less waste, helping us move towards a more circular, eco-friendly economy.

On top of that, there are some exciting new tech innovations that could make production even more sustainable. For example, switching to renewable energy sources during manufacturing can seriously cut down on greenhouse gas emissions. Plus, improvements in alloy technology could lead to lighter, more efficient busbars, which means less material is needed and overall electrical systems run more smoothly. Combining these smart practices and tech advances is probably the way forward if we want the copper-aluminum busbar market to stay sustainable—it's all about reducing our environmental footprint and being more responsible with natural resources. It’s an ongoing journey, but these steps definitely set us on the right track.

Market Trends Influencing Innovation Strategies

So, the copper aluminum busbar market right now is going through some pretty big changes. You can really see a lot of the newer trends shaping how companies are approaching innovation. For example, there’s a huge push for energy efficiency. As industries look for ways to cut costs and lessen their environmental footprint, manufacturers are really focusing on designing busbars that don’t just conduct electricity well but also cut down energy loss. It’s kind of like a race to find smarter, more efficient solutions. And because of that, we’re seeing a lot more collaboration — engineers, tech developers, and manufacturers teaming up to create products that meet all those strict new regulations and what customers are actually demanding.

Another big factor is the rise of smart grid tech. As the whole energy infrastructure evolves, integrating smarter communication and monitoring tools into busbars has become a must. Not only does this make power distribution more reliable, but it also opens the door for real-time data analysis. That means utilities and industrial players can make better, faster decisions. So, a lot of the current innovation efforts are now centered around adding digital features into busbar designs, helping users stay flexible and efficient even as the energy world keeps changing fast.

Case Studies of Successful Innovations in the Industry

The copper-aluminum busbar market has really been going through some exciting changes lately, with new innovations that boost both efficiency and sustainability. For example, there's this pretty fascinating case where a top manufacturer created a hybrid busbar that mixes copper and aluminum in a special proprietary ratio. This combo makes the busbars about 30% lighter, and yet, they don’t lose any of that good electrical conductivity. It’s a game-changer because it makes installation much easier and cuts down on material costs—especially when you're dealing with big electrical setups.

Then there’s also some cool stuff happening on the production side. One innovative company has adopted this cutting-edge extrusion process that not only makes the busbars stronger, but also improves the surface finish—helping to keep resistance low and prevent wear over time. Thanks to this, their products last around 20% longer, which really adds up in terms of savings and less maintenance for customers. All in all, these examples show how continuous improvements in materials and manufacturing tech are setting a new bar for what we can expect from copper-aluminum busbars in terms of performance and durability.

Future Prospects for Copper Aluminum Busbar Applications

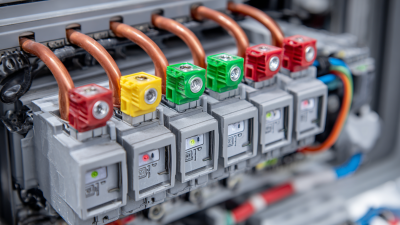

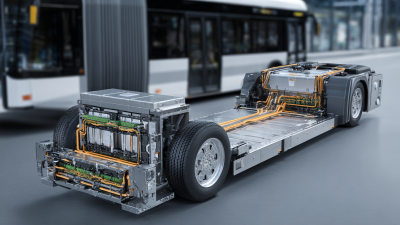

The copper-aluminum busbar market is currently going through quite a shake-up, thanks to changing industrial needs and new tech breakthroughs. Companies are really pushing to boost efficiency and cut down costs, which has led to a big jump in demand for these busbars—combining copper’s great conductivity with aluminum’s lightweight qualities. They’re super important for spreading out electrical power, so you’ll find them playing a key role in areas like renewable energy, train systems, and data centers. And with more investments flowing into green tech, the future looks pretty bright for copper-aluminum busbars—they’re poised to be at the heart of smarter, more efficient energy distribution systems.

Looking ahead, the renewable energy scene seems especially promising. Solar farms and wind power setups are starting to use these busbars because they’re lighter and easier to install. Plus, with the rise of electric vehicles (EVs), there’s a whole new opportunity for these busbars to shine. As the auto industry shifts gears toward electric, having advanced busbar tech is gonna be crucial for keeping batteries running smoothly. All in all, it’s clear that copper-aluminum busbars are not only versatile but also key players in building a more sustainable and innovative energy future.

The Essential Guide to Choosing Between Custom Rigid Copper and Aluminum Bus Bars for Your Application

In the decision-making process for selecting bus bars, the choice between custom rigid copper and aluminum options is paramount. The essential properties of these materials dictate their suitability for various applications. According to a recent industry report, copper bus bars demonstrate superior electrical conductivity, boasting about 60% better conductivity compared to aluminum. This makes copper the preferred choice for environments where efficiency and performance are critical, especially in demanding sectors such as power generation and distribution.

Sichuan Myway Technology Co., Ltd., with over 17 years of CNC machining expertise, specializes in the fabrication of high-quality copper bus bars tailored to meet user specifications. Their rigid copper bus bars are precisely CNC machined from copper or aluminum sheets, which allows for intricate designs that can include rounded or chamfered edges. The rounded design option is particularly advantageous, as it minimizes the risk of point discharge, a common issue in high-voltage applications. This attention to detail ensures that the bus bars not only convey current effectively but also enhance the longevity and reliability of the electrical connections they support.

Moreover, the demand for custom bus bars is on the rise, driven by the increasing complexity in electrical systems. According to market analysis, the global busbar market is projected to grow significantly, reaching new heights as industries adapt to more specialized electrical requirements. Thus, understanding the nuances of rigid copper versus aluminum bus bars empowers engineers and procurement teams to make informed decisions that align with their operational goals.

FAQS

: Technological advancements enhance busbar efficiency and performance by introducing smart busbar systems integrated with IoT capabilities, allowing for real-time monitoring and predictive maintenance, reducing downtime, and optimizing energy consumption.

Organizations can improve busbar efficiency through regular inspections, upgrades to modern materials that enhance conductivity, implementation of automation in production processes, and investing in workforce training.

Energy efficiency is crucial as industries aim to reduce operational costs and environmental impacts, leading companies to develop busbar solutions that minimize energy loss and meet regulatory standards.

Smart grid technologies improve the reliability of power distribution and facilitate real-time data analytics, prompting innovation strategies to incorporate advanced communication and monitoring systems into busbar solutions.

Copper aluminum busbars are essential in sectors like renewable energy, rail transport, and data centers, where they support efficient electrical power distribution.

They are being adopted in solar power plants and wind energy installations due to their lightweight properties and ease of installation, enhancing efficiency in renewable energy applications.

In the automotive industry, particularly with the rise of electric vehicles (EVs), advanced busbar technologies are critical for optimizing battery management systems and integrating electric components.

Leveraging data analytics provides insights into usage patterns and performance metrics, allowing for informed decisions regarding upgrades and maintenance schedules, ultimately enhancing operational efficiency.

Companies are fostering a culture of innovation through collaboration with technology providers, focusing on energy-efficient designs, and incorporating digital technologies into their busbar products.

The future outlook is promising, with expanding applications in renewable energy and electric vehicles, supported by increasing investments in green technologies and innovative approaches to energy distribution.

Conclusion

The Copper Aluminum Busbar Market is really heading into an exciting phase of change, but it’s not without its hurdles. You see, current designs have some issues—like how efficient they are and how sustainable they can be—which have become more pressing lately, especially with new tech developments and everyone’s growing environmental concerns. Companies like Sichuan D&F Electric Co., Ltd. understand this all too well. As a big player in electrical connection parts, they realize it’s crucial to come up with innovative solutions that not only make busbars more efficient but also reduce the environmental footprint of their production processes.

Plus, if you keep an eye on the market trends, it’s pretty obvious that there’s a strong push towards smarter tech and eco-friendly innovation. Companies that jump on these trends are the ones that will stay ahead of the game. There are some pretty inspiring success stories showing how innovations can really improve applications, which means the future of this industry looks pretty promising. All in all, firms like D&F are in a great spot to help steer the industry toward a more efficient and sustainable way of designing and using busbars. It’s an exciting time for sure!

Related Posts

-

Exploring Unique Custom Molding Part Alternatives for Global Buyers

-

Essential Checklist for Global Buyers: Navigating Gpo3 Machining Procurement

-

Ultimate Guide to Choosing the Right Flexible Busbar Connectors for Your Systems

-

How to Achieve Maximum Energy Efficiency with H Class Insulation Solutions

-

Identifying Challenges with Electric Vehicle Busbar Innovations

-

The Ultimate Checklist to Choosing the Best Copper Bus Bar for Global Procurement