Ultimate Guide to Choosing the Right Flexible Busbar Connectors for Your Systems

Table of Contents

- Understanding the Importance of Flexible Busbar Connectors in Modern Electrical Systems

- Key Factors to Consider When Selecting Flexible Busbar Connectors

- Different Types of Flexible Busbar Connectors and Their Applications

- Common Mistakes to Avoid When Choosing Flexible Busbar Connectors

- Future Trends in Flexible Busbar Connector Technologies

- Maintenance Tips for Ensuring Longevity of Flexible Busbar Connectors

- FAQS

- Conclusion

- Related Posts

In the fast-changing world of electrical systems, you really can't overlook how important Flexible Busbar Connectors are. I came across a recent report from MarketsandMarkets, and it’s pretty wild — they’re saying the global busbar market could hit around USD 15.5 billion by 2025. That just goes to show how much folks are looking for reliable and efficient connection components nowadays. Flexible Busbar Connectors are key in making sure everything runs smoothly and safely, especially because modern power distribution needs to be pretty adaptable. As someone who's been in this industry for a while, I can tell you that Sichuan D&F Electric Co., Ltd. has been a trusted name since 2005, constantly coming up with innovative solutions that really cater to their clients’ needs. So, if you’re trying to figure out how to pick the right Flexible Busbar Connectors, this guide is gonna give you some solid tips and insights to help make your electrical systems run better and more reliably.

Understanding the Importance of Flexible Busbar Connectors in Modern Electrical Systems

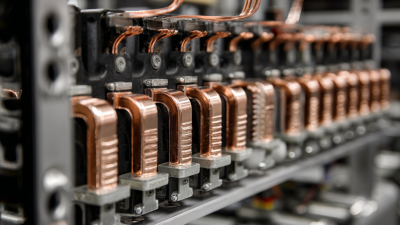

Flexible busbar connectors are pretty essential when it comes to keeping modern electrical systems running smoothly and reliably. Basically, they act as the link between various parts, making sure power flows seamlessly—and they also handle movement and heat expansion without a hitch. If you look at a report from Research and Markets, they say the global market for these flexible connectors is expected to hit around $19.57 billion by 2027. And it’s not slowing down—growing at a compound annual rate of about 5.8% from 2020 to 2027. That growth really reflects how more and more industries—like renewable energy projects and data centers—are on the lookout for flexible, space-efficient electrical solutions.

On top of that, there’s increasing demand for these connectors because they boost safety and cut down on installation time. A study by Grand View Research pointed out that flexible busbars help reduce resistive losses and manage heat better, which means they not only improve performance but can also extend the lifespan of electrical equipment. As the push for energy efficiency and advanced tech integration gets stronger, picking the right flexible busbar connectors becomes super important for developers who want to keep their systems optimized and running sustainably in this fast-moving electrical world.

Ultimate Guide to Choosing the Right Flexible Busbar Connectors for Your Systems

| Connector Type | Current Rating (A) | Voltage Rating (V) | Material | Temperature Range (°C) | Application |

|---|---|---|---|---|---|

| Flexible Copper Connector | 300 | 600 | Copper | -40 to 85 | Power Distribution |

| Flexible Aluminum Connector | 200 | 480 | Aluminum | -20 to 70 | Renewable Energy Systems |

| Flexible Busbar Joint | 150 | 400 | Copper/Aluminum | -10 to 60 | Industrial Machinery |

| Flexible Insulated Connector | 250 | 690 | Copper | -30 to 90 | Data Centers |

Key Factors to Consider When Selecting Flexible Busbar Connectors

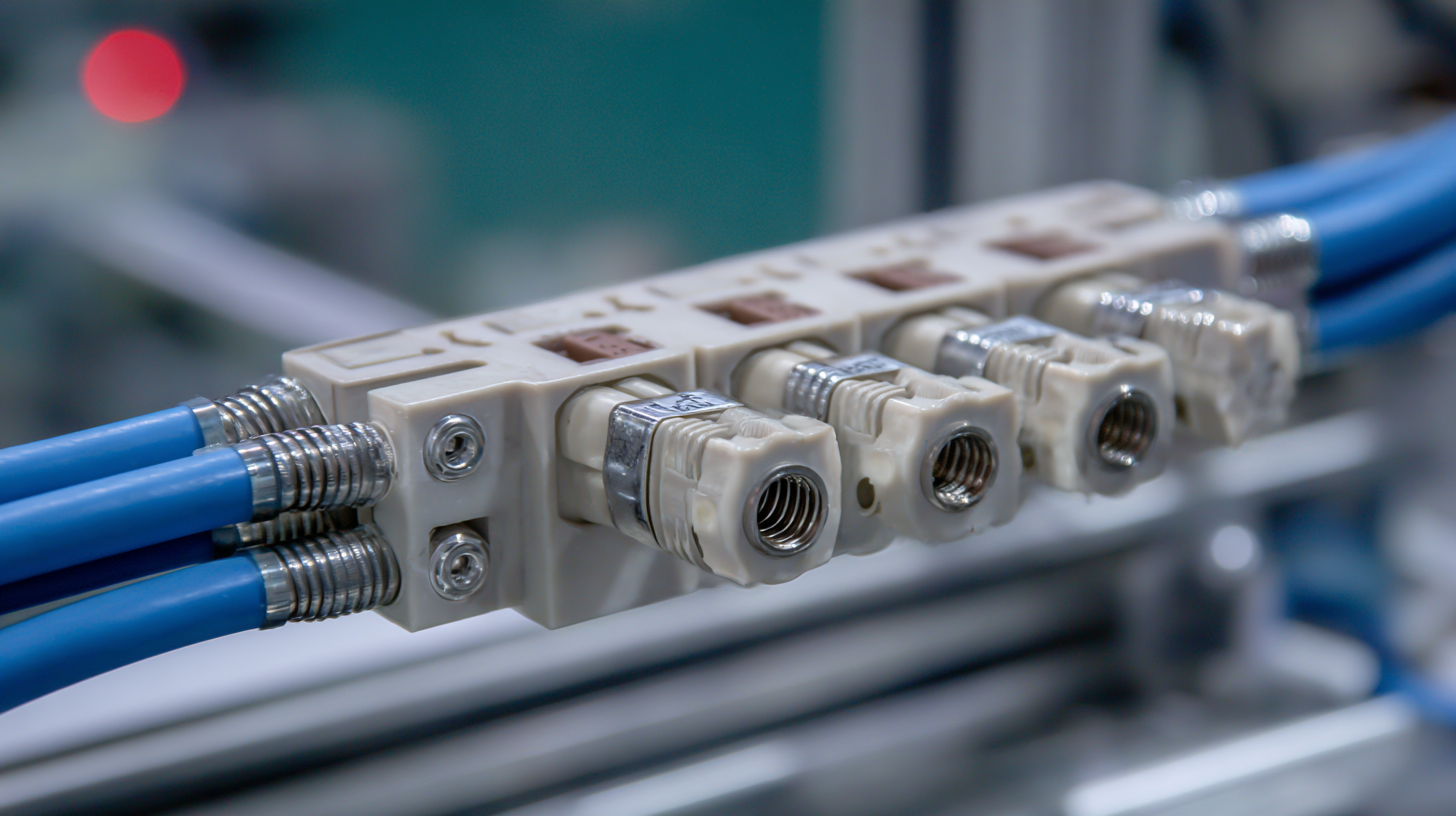

When you're picking flexible busbar connectors for your setup, there are a few key things you really want to keep in mind to make sure everything runs smoothly and stays reliable. First off, the electrical ratings are super important — basically, how much voltage and current they can handle. According to the IEC, it’s smart to go for connectors that can support more than your maximum expected load. That way, you avoid overheating or any nasty failures down the line. A good rule of thumb is to choose ones that can handle at least 125% of what you anticipate — that extra safety margin is always a good idea, especially if your system gets a bit demand-heavy.

Thermal management is another biggie. Flexible busbars often find themselves in environments where temperatures swing around quite a bit. Interestingly, the Electrical Engineering Research Association actually found that if the thermal distribution isn’t handled right, the lifespan of those connectors can drop by about 20%. So, picking materials like copper or aluminum, which are great at conducting heat, can really help keep things cool and working efficiently. And don't forget about how flexible and durable the connectors are—since they’ll be subjected to bending and vibrations, you want something that won’t break or crack easily. Plus, having connectors that are flexible makes installation way easier, especially if you're dealing with tight spaces or complex setups.

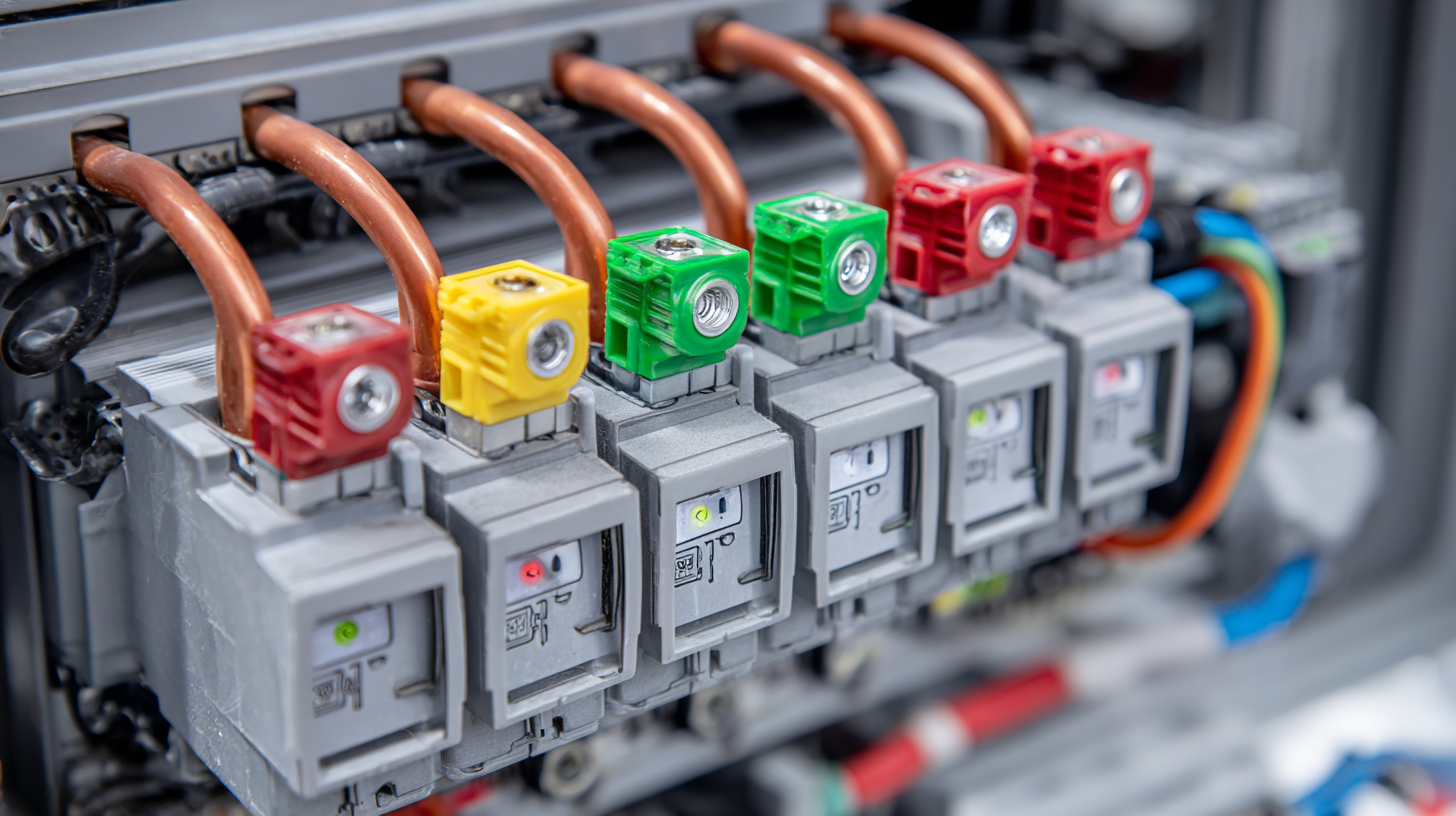

Different Types of Flexible Busbar Connectors and Their Applications

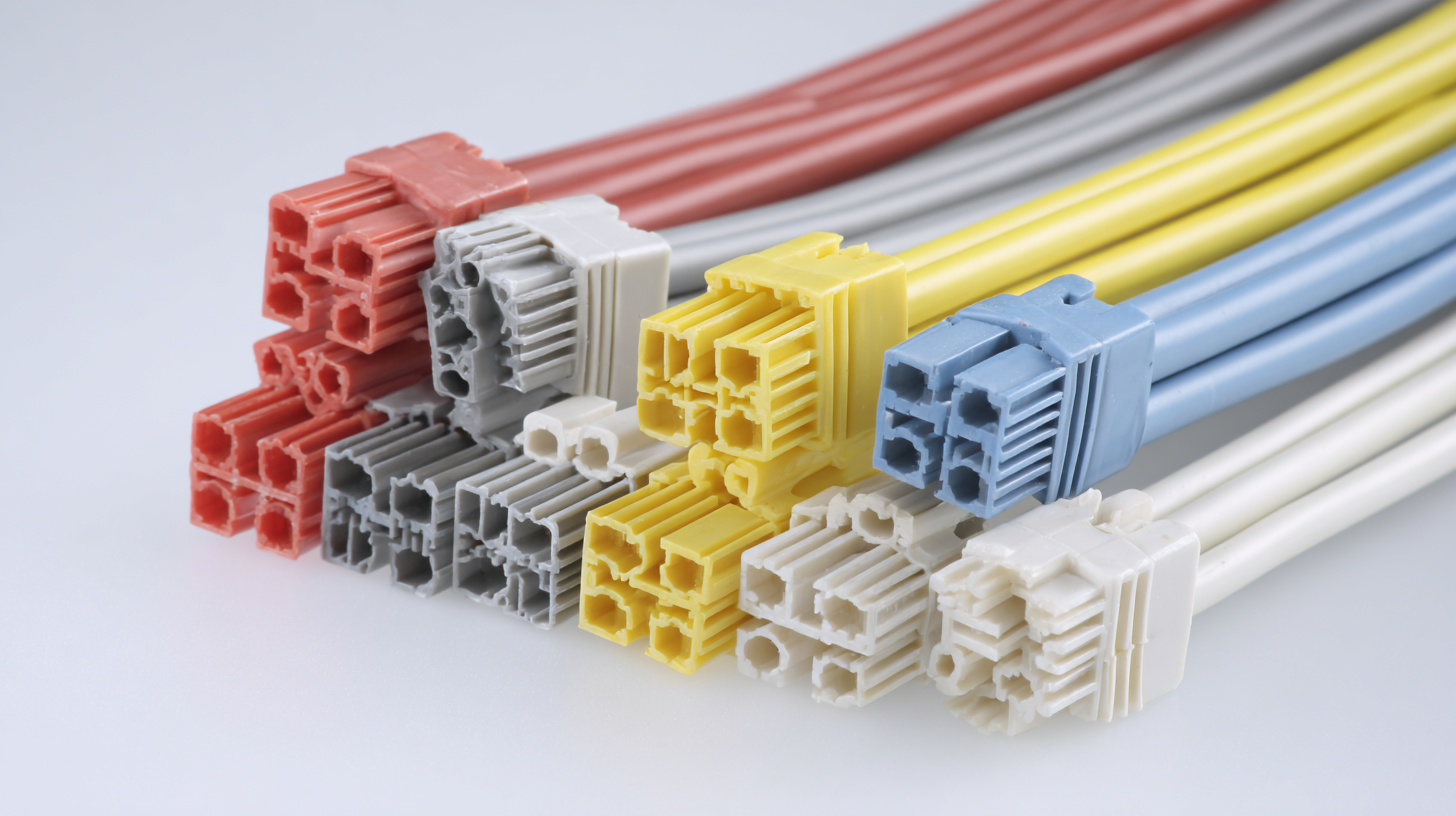

When you're choosing flexible busbar connectors for your electrical setups, it’s really important to understand the different types out there and what they’re best suited for. They come in a few designs—mainly single-layer and multi-layer. The single-layer ones are great for simpler jobs, especially when space is tight. They’re reliable and don’t need much routing, so they’re kind of the go-to for straightforward applications. On the flip side, multi-layer connectors are much better if you’re dealing with higher current loads. They’re perfect for industrial kind of environments where you need something tough that can handle demanding conditions.

Another thing to think about is the material of these connectors. Copper and aluminum are the main players here. Copper usually offers better conductivity, so it’s a bit more reliable, but aluminum is lighter and tends to be cheaper. Depending on what you’re working on—like renewable energy setups, data centers, or heavy machinery—the material choice can seriously affect how well your system performs and how dependable it is. Getting a good grasp of these differences will help you pick the right connectors and keep your electrical systems running smoothly and efficiently.

Common Mistakes to Avoid When Choosing Flexible Busbar Connectors

Looking to pick out flexible busbar connectors? One of the most common mistakes people make is not paying enough attention to the temperature ratings of the materials. I mean, according to a report from the IEEE, almost 17% of system failures are actually due to poor thermal management. So, it's really important to choose connectors that can handle the temperatures your system will run at, without losing conductivity. If you overlook this, you’re risking overheating, which can eventually lead to system damage.

And here’s another thing — a lot of folks forget about the mechanical stress these connectors will face once they're in the system. The IEC’s research has shown that if connectors undergo too much mechanical stress, they can get fatigued over time, which could cause connection failures down the line. To steer clear of that, it’s a good idea to think about how the connectors will move and what kind of environmental conditions they’ll be exposed to. Picking connectors that are flexible and built to last, and that match your specific needs, can really make a big difference in how reliable and long-lasting your setup turns out to be.

Future Trends in Flexible Busbar Connector Technologies

As we look ahead at the future of flexible busbar connector tech, it’s really important to appreciate how energy storage plays a huge role in bringing renewable energy sources into the mix. With everyone talking about decarbonization these days, new and innovative flexible busbar connectors are popping up to keep up with the growing needs for energy efficiency and sustainability. These connectors don’t just make power distribution more reliable—they also support the latest in energy storage tech, which is pretty much key to pushing forward a cleaner, greener energy landscape.

On top of that, the way we’re seeing advancements in current-sensing tech totally changing the game for energy management—especially in electric vehicles. The high-precision, coreless current sensors are really making a difference, giving us more accurate ways to monitor and distribute power. As manufacturers explore these cool new solutions, the connectors need to keep pace to make sure everything plays nicely together in terms of compatibility and performance. That combo of smart energy storage innovation and flexible connector tech is really what’s going to shape the energy systems of the future. It all comes down to designing smarter, more adaptable solutions if we want a truly sustainable energy future, ya know?

Maintenance Tips for Ensuring Longevity of Flexible Busbar Connectors

When it comes to keeping flexible busbar connectors in good shape for the long haul, regular maintenance is honestly your best friend. Just taking the time to do routine inspections can really catch small issues—like signs of wear or tear—before they turn into bigger, more costly problems. A simple thing you can do is check for corrosion or oxidation now and then, since these can mess with the electrical connection. Also, it's super important to keep the connectors clean—dirt and grime might seem minor, but they can actually insulate the connections and cause them to overheat, which is obviously not what you want.

On top of that, make sure these connectors aren’t rattling around too much. If you're dealing with vibrations—say, in a busy or dynamic setting—securing them properly can make all the difference. Using mounting solutions that reduce movement helps keep everything stable. Think of it like taking care of your garden hoses—if you prevent kinks and keep the water flowing smoothly, they last way longer. The same idea applies here: regular maintenance routines can really make sure your busbar connectors stay in top shape for years. And, of course, choosing high-quality materials from trusted brands like Sichuan D&F Electric Co., Ltd. just adds an extra layer of durability, helping them stand up against environmental challenges and mechanical stress over time.

FAQS

: Flexible busbar connectors are components that link various parts of electrical systems, enabling efficient and reliable power transfer while accommodating movement and thermal expansion. They are crucial for enhancing system efficiency and reliability.

The flexible busbar market is expected to grow significantly due to rising demand for adaptable and space-saving electrical solutions, particularly in industries like renewable energy and data centers, with projections estimating a market value of $19.57 billion by 2027.

Flexible busbars minimize resistive losses and thermal management issues, which enhances the performance of electrical equipment and reduces the risk of overheating and failure, thereby improving overall safety.

Key factors include the electrical rating (voltage and current capacity), thermal management (materials with good thermal conductivity), and the flexibility and mechanical properties of the connectors to withstand bending and vibrations.

Connectors should be selected to handle at least 125% of the expected load to ensure safety and prevent overheating in high-demand applications.

There are single-layer and multi-layer connectors. Single-layer connectors are used for simpler applications, while multi-layer connectors can handle higher current loads, making them suitable for industrial uses.

The most common materials are copper, which offers superior conductivity, and aluminum, which is lighter and more cost-effective. The choice of material influences the efficiency and reliability of electrical systems.

Proper thermal management is essential because improper thermal distribution can decrease the lifespan of connectors by up to 20%. Materials with excellent thermal conductivity help dissipate heat effectively, enhancing connector durability.

Flexible busbar connectors are used in various applications, including renewable energy systems, data centers, and heavy machinery, where reliability and efficiency are critical.

Increased flexibility allows for easier installation and adaptability in systems with limited space, making it essential for connectors used in dynamic environments.

Conclusion

Hey there! So, in our 'Ultimate Guide to Choosing the Right Flexible Busbar Connectors for Your Systems,' we really dive into how these connectors actually impact today's electrical setups. It’s pretty eye-opening to see how they help distribute power smoothly, all while handling movement and heating that happen in real-world scenarios. When you're picking out flexible busbar connectors, it's good to keep an eye on things like what they're made of, how much current they can handle, and the environment they'll be working in—stuff that really makes a difference in performance.

We also go through the different types of flexible busbar connectors out there, what they’re best suited for, and share some common pitfalls to watch out for during the selection process—believe me, avoiding these can save you quite a bit of hassle. Plus, we peek into future trends in connector tech, which could really make things even better down the line. And don’t forget—keeping these connectors in good shape is key to making them last longer. We share some practical tips on how to maintain them properly. At Sichuan D&F Electric Co., Ltd., we’re all about offering top-quality electrical parts, including flexible busbar connectors, that fit perfectly with your system’s needs. We’re here to help you get it right from the start!"

Related Posts

-

The Future of China Epoxy Glass Fiber Sheet in Global Markets

-

Solutions for Enhancing Electrical Efficiency with Silver Plated Copper Bus Bars

-

Exploring Alternative Options to Best Gpo3 Sheets for Savvy Global Buyers

-

Exploring Unique Custom Molding Part Alternatives for Global Buyers

-

How to Achieve Maximum Energy Efficiency with H Class Insulation Solutions

-

How to Choose the Right Flexible Busbar Solutions for Your Industrial Needs