Understanding the Importance of Dc-Link Busbar in Modern Power Systems

Table of Contents

- The Role of DC-Link Busbars in Enhancing Power Efficiency in Modern Systems

- Key Parameters to Consider When Designing a DC-Link Busbar

- Impact of DC-Link Busbar on Power Quality and System Stability

- Case Studies: Successful Implementations of DC-Link Busbars in Industry

- Future Trends in DC-Link Busbar Technology and Materials

- Guidelines for Maintenance and Inspection of DC-Link Busbars in Power Systems

- Innovative Applications and Benefits of 3240 Epoxy Phenolic Glass Cloth Base Laminated Sheets in Modern Industries

- FAQS

- Conclusion

- Related Posts

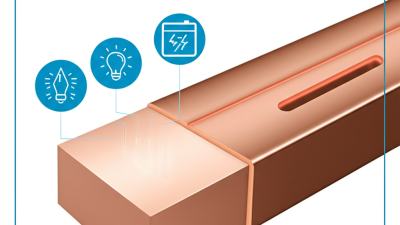

In today’s fast-changing world of power systems, you really can’t overlook the importance of the DC-Link Busbar. This small but mighty component is key when it comes to making sure energy flows smoothly between inverters and rectifiers. Whether it’s in renewable energy setups or electric vehicle charging stations, it helps boost performance and keeps things running reliably.

Industry insiders say that the global busbar market is expected to hit around $21.18 billion by 2027 — all thanks to the rising demand for smarter, more efficient power distribution solutions. And speaking of industry leaders, Sichuan D&F Electric Co., Ltd., has been around since 2005 and has built a solid reputation as a trusted manufacturer and supplier of electrical connection parts and insulation components.

As everyone is pushing toward more efficient and sustainable energy solutions, understanding the critical role of the DC-Link Busbar is going to be super important for anyone trying to stay ahead in this game — whether you're innovating or just looking to improve existing systems.

The Role of DC-Link Busbars in Enhancing Power Efficiency in Modern Systems

In today’s modern power systems, DC-link busbars are really becoming key players—helping boost overall efficiency quite a lot. Basically, they make it easier to connect different power electronics directly, which means less energy gets lost when you're converting from AC to DC. According to a report by the International Energy Agency, adding advanced DC networks can improve energy efficiency by up to 30% compared to those old-school AC setups. That kind of boost is super important for things like renewable energy projects or electric vehicle charging stations, where fast and reliable power delivery isn’t just nice to have—it’s essential.

Plus, when you design and implement these DC-link busbars thoughtfully, it can really pay off. You get better reliability and cut down on maintenance costs. The IEEE Power Electronics Society points out that systems with well-optimized DC-link setups see about a 25% reduction in downtime because they handle higher stresses better. As industries lean more toward sustainability, these busbars are only getting more important. They help simplify power distribution while cranking up efficiency, making them vital in the future of modern electrical systems.

Key Parameters to Consider When Designing a DC-Link Busbar

When you're designing a DC-Link busbar for modern power systems, there are quite a few important things to keep in mind to make sure everything runs smoothly and reliably. First off, the current-carrying capacity is a big deal—basically, you want the busbar to handle the maximum expected current without getting too hot. Interestingly, according to a report by the International Energy Agency, as demand for renewable energy keeps growing, we're probably going to see DC busbar ratings jump by about 30% over the next decade to handle all that new power.

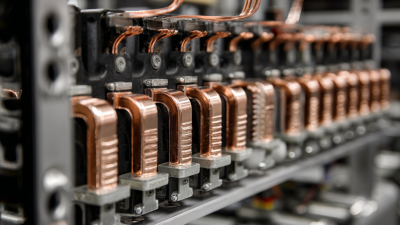

Another key factor is thermal management. Good heat dissipation isn’t optional—it’s essential if you want your system to stay in good shape. Using advanced materials like aluminum or copper, which can come with built-in cooling features, can really boost heat transfer efficiency—by around 25%, actually. And don’t forget about mechanical strength. The busbar needs to withstand stresses from things like thermal expansion and vibrations, especially in high-power setups. The American National Standards Institute recommends designing with sturdy support structures so everything stays stable.

Last but not least, electromagnetic interference, or EMI, is something you’ve gotta think about. DC-Link busbars can generate quite a bit of EMI, which could mess with nearby electronic equipment—especially when your power systems are packed tight. Luckily, by using proper shielding and smart layout strategies (as suggested in the latest IEEE standards), you can drastically cut down on EMI, making your system more reliable and performing better overall.

Understanding the Importance of Dc-Link Busbar in Modern Power Systems - Key Parameters to Consider When Designing a DC-Link Busbar

| Parameter | Description | Recommended Value | Impact on System |

|---|---|---|---|

| Current Rating | Maximum continuous current the busbar can carry | 1000 A | Essential for reliability and efficiency in power distribution |

| Voltage Rating | Maximum operating voltage of the busbar | 1000 V | Ensures safe operation and compliance with standards |

| Thermal Management | Ability to manage heat generation | Cooling system rated at 80°C | Prevents thermal overload and extends lifespan |

| Material | Type of material used for construction | Copper | High conductivity ensures minimal losses |

| Size & Dimensions | Physical dimensions affecting installation | 50 mm x 10 mm | Affects space utilization and thermal performance |

Impact of DC-Link Busbar on Power Quality and System Stability

The DC-Link Busbar might not be a household name, but it’s actually pretty crucial when it comes to modern power systems. It really helps improve power quality and keeps everything running smoothly and steadily. And get this—according to the Global Energy Storage Market Report 2023, using advanced DC-Link Busbars can boost voltage stability and cut down harmonic distortion by as much as 30%. That’s pretty huge because it helps smooth out voltage fluctuations, making sure sensitive tech—like in telecom gear and data centers—runs efficiently and reliably.

On top of that, having a sturdy DC-Link Busbar design makes a big difference in overall system stability. The IEEE Power Electronics Society did some research, and they found that systems with optimized busbar setups respond about 20% faster during those sudden spikes or dips in load. That kind of responsiveness is totally vital, especially for renewable energy sources like solar and wind, which can be a bit unpredictable. By handling the current flow better and cutting losses through newer materials and smarter arrangements, the DC-Link Busbar really acts as the backbone of energy distribution—helping to keep the power steady and reliable in a world that’s constantly getting more electrified.

Case Studies: Successful Implementations of DC-Link Busbars in Industry

DC-Link busbars are pretty essential in today's power systems—they basically serve as the backbone for transmitting energy between different parts like converters and inverters. You can see an awesome example of this in the renewable energy world, where Siemens AG has successfully used DC-Link busbars in their offshore wind farms. According to a report from the International Renewable Energy Agency (IRENA), power transmission became about 20% more efficient thanks to these busbars, mainly because of fewer losses. It really shows how effective DC-Link tech can be, especially in big-scale projects.

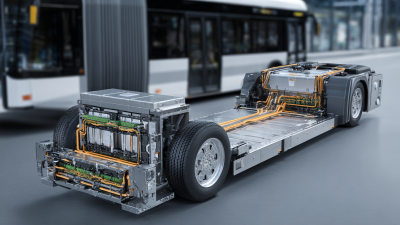

And then there's the electric vehicle scene—Tesla, for instance, is using DC-Link busbars in their Gigafactories. A study from the National Renewable Energy Laboratory pointed out that by designing these busbars better, Tesla managed to cut down weight and improve heat management. This led to about a 15% boost in manufacturing efficiency. Not only does that mean they can produce more cars faster, but it also helps lower operational costs. Overall, it just highlights how valuable DC-Link busbars are, especially when demand is high and efficiency really matters.

Future Trends in DC-Link Busbar Technology and Materials

Looking ahead, it’s pretty exciting to see where DC-link busbar tech is headed. With the growing need for more efficient and greener power systems, we're seeing some pretty cool innovations. Researchers are now exploring new materials—think lightweight composites and more advanced metals—that can boost performance and help with thermal management. The goal? Cutting down on energy losses and making these systems more reliable overall. That’s a big deal, especially for renewable energy setups and electric vehicles, where every bit of efficiency counts.

On top of that, there’s a real buzz about adding smart tech into these busbars. Thanks to the Internet of Things (IoT), future busbars might be able to monitor themselves in real-time. Imagine catching faults early or predicting maintenance needs before something breaks—that kind of stuff could make power management way smoother and cut down on downtime. As industries keep moving toward electrification and renewables, these advancements are kinda rewriting the game for DC-link busbars, turning them into key players in the modern energy scene.

Guidelines for Maintenance and Inspection of DC-Link Busbars in Power Systems

DC-link busbars might not be the sexiest part of power systems, but let me tell you—they’re pretty important. Basically, they act as the highway for direct current, helping energy move smoothly between different parts of the system. To keep things running nice and smoothly, it’s super important to give these busbars a regular check-up. You’ll want to look out for any signs of physical damage, make sure all the electrical connections are tight, and keep an eye out for overheating spots. Sticking to these simple tips can save you from costly surprises down the line—like system outages or damaged equipment.

When you’re inspecting the busbars, don’t forget safety first—wear the right PPE and follow all safety procedures to keep hazards at bay. Also, it’s a good idea to set up a maintenance routine that matches how often your system runs; this way, you can catch issues early before they turn into big problems.

Another key thing is keeping the busbars clean. Dust, grime, and other gunk can mess with performance, so a quick clean now and then really helps. A dust-free, tidy busbar conducts electricity better and lasts longer. During your visual inspections, keep an eye out for corrosion or loose nuts and bolts—these small issues can seriously threaten the whole system.

Here’s a pro tip: use non-conductive brushes and cleaning products made for electrical parts. You don’t want to accidentally cause more issues by using the wrong stuff. And, don’t forget to jot down what you do and find—keeping a maintenance log is like having a health record for your busbars, helping you track how they’re doing over time.

Innovative Applications and Benefits of 3240 Epoxy Phenolic Glass Cloth Base Laminated Sheets in Modern Industries

The innovative applications of 3240 Epoxy Phenolic Glass Cloth Base Laminated Sheets are transforming modern industries, particularly in the electrical and electronic sectors. This material, known for its alkali-free woven glass cloth impregnated with epoxy phenolic thermosetting resin, exhibits remarkable mechanical and electrical strength, making it essential for electrical insulation in motors and transformers. Notably, it retains performance even in humid conditions and is compatible with transformer oils, ensuring reliability in challenging environments.

According to industry reports, the global market for epoxy composites is expected to grow significantly, driven by the increasing demand for lightweight and durable materials in automotive, aerospace, and electrical applications. The 3240 sheets not only meet substantial mechanical and electrical properties requirements but also comply with stringent environmental standards, having passed REACH and RoHS tests. This versatility allows for applications across a wide range of industries, enhancing productivity and safety in electrical systems.

Available in thicknesses ranging from 0.5mm to 200mm and various sheet sizes, including 1500mm x 3000mm, the adaptability of these laminated sheets facilitates their integration into diverse manufacturing processes. This combination of innovation, safety, and high performance positions 3240 Epoxy Phenolic Glass Cloth Base Laminated Sheets at the forefront of modern material solutions, promising to redefine efficiency and sustainability in industrial applications.

FAQS

: DC-link busbars facilitate direct connections between power electronics, minimizing energy losses associated with AC-DC conversions and significantly enhancing power efficiency.

The integration of advanced DC networks can improve energy efficiency by up to 30% compared to traditional AC systems.

DC-link busbars are essential in applications such as renewable energy integration and electric vehicle charging stations, where rapid and reliable power delivery is crucial.

Well-optimized DC-link infrastructures can lead to nearly a 25% reduction in system downtime due to their ability to withstand higher operational stresses.

Future trends include the use of lightweight composites and advanced conductive metals to enhance performance and thermal management, as well as the integration of smart technology for real-time monitoring.

Smart technologies enable real-time monitoring capabilities that support better fault detection, predictive maintenance, and proactive management of power distribution, increasing overall system efficiency.

Their ability to streamline power distribution while enhancing efficiency positions DC-link busbars as essential for modern electrical systems in the context of sustainable practices.

Emerging materials are aimed at reducing losses and improving overall system reliability, making DC-link configurations more viable in renewable energy applications and electric vehicles.

The strategic design and implementation of DC-link busbars not only enhance operational reliability but also contribute to significant reductions in maintenance costs.

This shift signifies a transformative era for DC-link busbars, positioning them as critical components in the evolving landscape of modern energy systems.

Conclusion

So, I recently came across an article titled "Understanding the Importance of Dc-Link Busbar in Modern Power Systems," and I gotta say, it really sheds light on just how vital these busbars are. Basically, they play a huge role in making power systems more efficient and stable these days. The article breaks down the key design points you need to keep in mind if you want these busbars to perform at their best, and it also talks about how they impact the overall quality of the power supply. It’s pretty interesting — they included some real-world examples to show how different industries are successfully using Dc-Link Busbars, which really highlights how they help keep things running smoothly and reliably.

It also touches on what’s coming next for this tech, like new materials that can handle the growing demands of modern electrical grids. Plus, it gives some handy tips on maintaining and inspecting these components so they last longer and stay in good shape. And on that note, Sichuan D&F Electric Co., Ltd., as a pretty reliable manufacturer, is actually in a good position to support the increasing need for quality electrical parts like Dc-Link Busbars in today’s power setups. Overall, it’s a pretty insightful read if you're into electrical systems or just curious about how they stay efficient and stable these days.

Related Posts

-

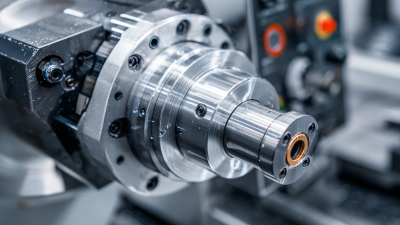

7 Essential Tips for Mastering Electrical Insulator Machining Efficiency

-

The Future of Innovation in the Copper Aluminum Busbar Market

-

Unlocking the Advantages of Bare Copper Strip in Electrical Applications for Energy Efficiency

-

Identifying Challenges with Electric Vehicle Busbar Innovations

-

Solutions for Enhancing Electrical Efficiency with Silver Plated Copper Bus Bars

-

How to Choose the Best Tin Plated Copper Bus Bar for Your Electrical Needs