The Ultimate Guide to Laminated Bus Bars for the EV Market: Optimizing Performance and Efficiency

Table of Contents

- Understanding Laminated Bus Bars: Key Components for EV Applications

- Benefits of Laminated Bus Bars in Electric Vehicle Design and Performance

- Maximizing Efficiency: Thermal Management in Laminated Bus Bars

- Future Trends: Innovations in Laminated Bus Bar Technology for EVs

- Sustainability Considerations: Eco-friendly Materials for Bus Bar Production

- Comparative Analysis: Laminated Bus Bars vs. Traditional Bus Bars in EVs

- Exploring the Advantages of China High Quality Laminated Bus Bars for Enhanced Electrical Performance

- FAQS

- Conclusion

- Related Posts

In the fast-changing world of electric vehicles (EVs), making sure everything runs smoothly and efficiently is pretty much everyone’s priority. One key piece that’s really making a difference is the use of Laminated Bus Bars in the EV market. These clever electrical connection solutions do a lot—they not only make power distribution more reliable but also help with thermal management and even cut down on the overall weight of the vehicle. Sichuan D&F Electric Co., Ltd., which has been around since 2005, is a name you can trust when it comes to top-quality electrical components and insulation parts. We’ve got a real knack for developing advanced Laminated Bus Bars, and we’re dedicated to helping EV makers boost performance while keeping sustainability in mind. In this guide, I’ll walk you through the main benefits of Laminated Bus Bars and why they’re such a big deal for the future of electric mobility. Basically, everyone involved—manufacturers and consumers alike—stands to gain from better efficiency and improved safety.

Understanding Laminated Bus Bars: Key Components for EV Applications

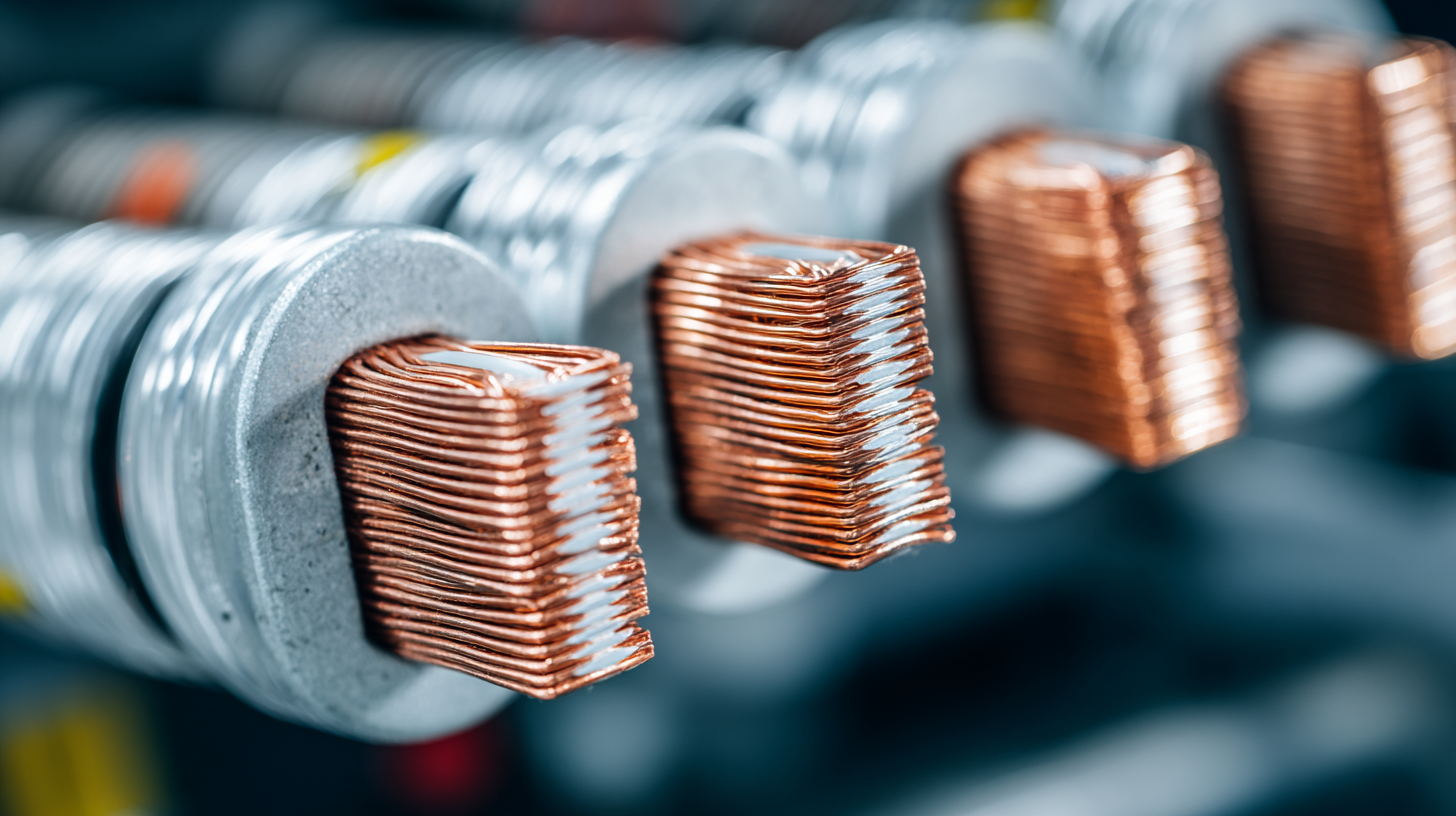

Laminated bus bars are really starting to play a bigger role in the electric vehicle (EV) scene. They’re basically essential parts that help boost electrical performance and efficiency. These multi-layer conductors are built to handle high currents without breaking a sweat, while also keeping electromagnetic interference in check — which is pretty important for EVs that need to be reliable and robust. They’re made from layers of conductive material separated by dielectric layers, which means they can distribute power reliably while also helping manage heat better for the critical parts.

Getting a grip on why laminated bus bars are so important? Well, it’s all about their structure and what they bring to the table. They’re super compact and lightweight, which helps cut down the size of the electrical systems inside EVs. Plus, their smart design cuts resistive losses and boosts overall conductivity, making it possible for manufacturers to pack more power into less space. As more and more people jump into electric vehicles, using laminated bus bars in vehicle designs isn’t just about performance—it’s also about being energy efficient. That means better cars on the road and an edge for brands in this rapidly evolving automotive world.

The Performance and Efficiency of Laminated Bus Bars in EV Applications

Benefits of Laminated Bus Bars in Electric Vehicle Design and Performance

Laminated bus bars are really becoming a key part of designing and improving electric vehicles nowadays. They do a pretty great job at cutting down electrical resistance, which means energy gets transmitted more efficiently—that’s a big deal for extending battery life and boosting overall vehicle performance. When you lose less power along the way, EVs can go farther on a single charge, which is exactly what everyone’s looking for with reliable and efficient transportation.

Quick tip: When you're working on laminated bus bars, it’s smart to pick materials that don’t expand or contract too much with temperature changes. This kind of stuff helps keep things stable and makes thermal management easier, meaning your bus bars will last longer and perform consistently even when things heat up or cool down.

Other than that, laminated bus bars are surprisingly tough mechanically, and they don’t bulk up the design too much. This opens up room in the vehicle, helping manufacturers scale down the size and even reduce weight. A lighter car uses less energy, which just adds to the efficiency overall.

And here’s another tip—try to pair your laminated bus bars with a solid cooling system. Keeping everything cool and under control temperature-wise means better performance and fewer worries about overheating or thermal failure down the line.

Maximizing Efficiency: Thermal Management in Laminated Bus Bars

When it comes to electric vehicles, thermal management in laminated bus bars is a big deal. It’s really what keeps the system running smoothly and efficiently. If the bus bars get too hot, they can overheat, which isn’t great — it shortens the lifespan of the components and can cause performance hiccups. That’s why using clever materials and smart designs to help dissipate heat better is a game-changer in EV design.

Here’s a little tip: adding thermal interface materials, or TIMs, can really boost how well heat moves away from the bus bars. It’s like giving the heat a clear path out, cutting down resistance and keeping everything at the right temp, so your system stays efficient.

And don’t forget about the shape and layout of those bus bars. Optimizing their design—making sure current flows evenly and reducing resistance—can help prevent those pesky hotspots that might lead to failures or slow performance. It’s all about cutting down risks before they become big issues.

All in all, focusing on solid thermal management strategies doesn’t just make EV power systems more reliable; it also helps push the whole sustainable transportation thing forward. Manufacturers really need to pay attention here if they want their vehicles to last longer and perform better over time.

Future Trends: Innovations in Laminated Bus Bar Technology for EVs

Laminated bus bar technology is really picking up speed, especially in the electric vehicle world. As manufacturers search for new ways to boost performance and efficiency, these laminated bus bars are becoming more and more essential. They offer better thermal management and a more compact design, which means they can handle higher currents without adding a ton of weight. Looking ahead, we’re expecting to see even more innovation—like using advanced materials that can handle higher temperatures and boost conductivity, making energy transfer in EVs even more efficient.

If you’re thinking about integrating laminated bus bars into your EV projects, my advice is to pay close attention to materials with high thermal conductivity and mechanical strength. Picking the right stuff helps make sure everything stays reliable, even when conditions aren’t perfect.

As EV demand keeps climbing, the smart technology side of laminated bus bars is set to grow too. Imagine sensors built right in to monitor their condition in real-time or adaptive cooling systems that tweak themselves on the fly—it’s all coming soon. These updates not only make vehicles perform better but also help push the industry toward its sustainability goals.

So, my tip? Keep an eye on the latest breakthroughs in material science. These can give you some pretty cool ideas for designing even more efficient laminated bus bars that keep up with the rapidly evolving EV market.

The Ultimate Guide to Laminated Bus Bars for the EV Market: Optimizing Performance and Efficiency

| Parameter | Value | Importance in EVs |

|---|---|---|

| Conductivity | > 90% IACS | Essential for efficient power transmission |

| Thermal Management | Prevents overheating and enhances safety | |

| Weight Reduction | Increases vehicle efficiency and range | |

| Size | Variable (customizable) | Customization for different EV designs |

| Cost | $50 - $150 per unit | Cost-effective solutions for mass production |

| Durability | > 10-year lifespan | Long-term reliability in EV applications |

| Eco-Friendliness | Recyclable materials | Supports sustainable vehicle manufacturing |

Sustainability Considerations: Eco-friendly Materials for Bus Bar Production

As the electric vehicle (EV) market keeps growing, there's a real buzz around finding efficient and eco-friendly parts. One of the key components here is laminated bus bars, which play a big role in distributing power safely and effectively. It’s pretty clear that switching to greener materials could make a big difference. For example, according to the International Energy Agency, EV sales hit about 6.6 million units in 2021 alone — which just shows how urgent it is for us to adopt more sustainable manufacturing practices. By using recyclable stuff like aluminum and copper, manufacturers aren’t just cutting down waste; they’re also shrinking their carbon footprints. That’s a win-win, especially with global sustainability goals getting more attention these days.

Oh, and a little tip — try sourcing materials that are certified by trusted eco-labels. It’s a simple way to make sure your bus bars are genuinely eco-friendly. On top of that, there are some pretty cool innovations happening with bio-based resins. These new materials can boost the eco-friendliness of laminated bus bars without messing up their performance. A study in the Journal of Cleaner Production even found that using such bio-based resins can cut greenhouse gas emissions during manufacturing by up to 30%. Not only does that help meet the stricter regulations out there, but it also looks good to environmentally conscious customers.

Here’s another tip: work closely with suppliers who really prioritize sustainable practices. That way, your whole supply chain gets a green upgrade, making everything more eco-friendly. Overall, by embracing these sustainable materials and new tech, manufacturers can run more efficient, high-performing laminated bus bars — all while doing their part for the planet. It’s a step toward a greener future for the EV industry, and honestly, who wouldn’t want to be part of that?

Comparative Analysis: Laminated Bus Bars vs. Traditional Bus Bars in EVs

In the fast-moving world of electric vehicles (EVs), choosing the right bus bars really makes a difference when it comes to performance and efficiency. Recently, laminated bus bars have been gaining popularity as a pretty awesome alternative to the old-school, traditional ones. They offer some pretty big advantages, especially when it comes to handling heat and conducting electricity smoothly.

Their layered design helps spread out heat better, which is super important for keeping things cool and running well—especially in high-demand stuff like EV powertrains. On the flip side, regular bus bars can sometimes develop hot spots, and that can mess with both how well everything works and safety too.

Here’s where Sichuan D&F Electric Co., Ltd. steps in. They’ve been leading the charge since 2005, right out of Deyang, Sichuan. The company's all about making solid electrical connection parts and insulation components, especially tailored for the EV world. Their laminated bus bars are a perfect example of top-notch engineering—designed not just to boost performance but to be tough and safe for the long haul.

As EVs keep growing in popularity, it’s pretty clear that laminated bus bars are the way to go compared to traditional types. And that totally lines up with what D&F stands for—quality, innovation, and reliable electrical solutions.

Exploring the Advantages of China High Quality Laminated Bus Bars for Enhanced Electrical Performance

Laminated bus bars, also known as composite or low inductance bus bars, have gained prominence in the electrical industry due to their superior performance characteristics. Specifically engineered with layers of copper conductive materials separated by thin dielectric layers, these bus bars provide remarkable efficiency in power distribution. Studies indicate that laminated bus bars can reduce electrical loss by up to 30% when compared to traditional bus bars, primarily due to their low inductance properties. The unique design minimizes electromagnetic interference, making them an ideal choice for high-frequency applications.

Incorporating laminated bus bars into electrical systems not only enhances reliability but also optimizes thermal management. According to a report by the Electrical Engineering Association, systems utilizing laminated bus bars can withstand higher current loads without significant temperature increases, thus prolonging the life of components. With current density capabilities reaching 1.2 A/mm² or more, engineers are encouraged to leverage these cutting-edge solutions to meet the demands of modern electrical architecture.

Moreover, the compact nature of laminated bus bars allows for streamlined designs, reducing the overall footprint of electrical installations. This compactness, combined with their robust performance, positions laminated bus bars as a preferred choice for industries seeking to enhance electrical performance while ensuring safety and efficiency. As industries continue to evolve, the integration of high-quality laminated bus bars will be essential in achieving optimal electrical performance.

FAQS

: Laminated bus bars are electrical components that significantly reduce electrical resistance, enhancing energy transmission efficiency. They are crucial for maximizing battery life and overall vehicle performance, allowing electric vehicles to achieve greater ranges on a single charge.

Laminated bus bars offer excellent mechanical strength in compact designs, enabling manufacturers to optimize space within the vehicle. This reduction in weight leads to lower energy consumption and better operational efficiency.

Thermal management is vital as it ensures laminated bus bars maintain optimal operating temperatures, reducing the risk of overheating and increasing the longevity of components.

Using materials with lower thermal expansion coefficients can enhance stability and thermal management. Additionally, employing thermal interface materials (TIMs) can improve thermal conductivity between bus bars and heat sinks.

Optimizing the geometry of laminated bus bars plays a critical role in thermal management and current distribution. Ensuring even current flow helps prevent localized hotspots, which can lead to performance issues or failures.

Effective thermal management strategies enhance the reliability and efficiency of EV power systems by preventing overheating, thereby contributing to the growth of sustainable transportation.

Designers should consider materials with lower thermal expansion coefficients, implement effective cooling systems, and focus on optimizing the geometry of the bus bars to minimize resistance and facilitate even current distribution.

By maintaining optimal operating temperatures and reducing the risk of thermal failures, laminated bus bars can extend the lifespan of electric vehicle components.

Conclusion

Laminated bus bars for the EV market are really becoming more and more important as the industry pushes to make electric vehicles better and more efficient. This guide dives into what makes laminated bus bars so essential—especially since they’re tailored specifically for EV applications. By boosting thermal management, these cool, innovative bus bars help improve both the design and the performance of electric cars.

Looking ahead, it’s pretty exciting to see how technology around laminated bus bars is evolving. Future trends are set to make them even more efficient, all while being more eco-friendly, thanks to the use of sustainable materials in their production. When you compare laminated bus bars to the traditional ones, there’s no contest—they really outperform the older technology and are a smart choice for manufacturers wanting to level up their EV game. Here at Sichuan D&F Electric Co., Ltd., we’re all about delivering high-quality electrical connection parts that support the ongoing growth and innovation in the electric vehicle world.

Related Posts

-

The Ultimate Checklist to Choosing the Best Copper Bus Bar for Global Procurement

-

Exploring Alternative Options to Best Gpo3 Sheets for Savvy Global Buyers

-

5 Key Insights on Winding Insulation Class for Optimal Motor Performance

-

Unlocking the Advantages of Bare Copper Strip in Electrical Applications for Energy Efficiency

-

How to Choose the Best Tin Plated Copper Bus Bar for Your Electrical Needs

-

Global Market Insights: Projecting the Future of Best Epoxy Fiberglass Tubes by 2025