How to Optimize Your Production Process with Gpo-3 Plastic for Efficiency and Sustainability

Table of Contents

- Understanding Gpo-3 Plastic and Its Benefits for Production Processes

- Identifying Key Areas for Efficiency Improvement with Gpo-3 Plastic

- Implementing Sustainable Practices in Production Using Gpo-3 Plastic

- Evaluating Cost-Effectiveness of Gpo-3 Plastic in Production Workflow

- Measuring and Analyzing Production Efficiency After Gpo-3 Integration

- Market Trends and Performance Indicators for GPO-3 (UPGM203) Unsaturated Polyester Glass Mat Laminated Sheet in Composites Industry

- FAQS

- Conclusion

- Related Posts

Today’s manufacturing world is changing pretty fast, and staying ahead really means adopting materials that are both efficient and eco-friendly. Take

Sichuan D&F Electric Co., Ltd., for example — they've been making electrical connection parts and insulation components since 2005, and they know how crucial it is to tweak their production methods to be more efficient while also caring for the environment. One material that's been catching on lately is Gpo-3 Plastic. It's loved for its excellent thermal insulation and durability. Industry reports say that using advanced plastics like Gpo-3 can boost energy efficiency in electrical products by up to 30%, plus it helps cut down on waste during manufacturing. As companies try to hit their operational goals and stay green at the same time, using Gpo-3 Plastic in production seems like a smart move — it’s a great way to stay competitive in the electrical industry while doing right by the planet.

Today’s manufacturing world is changing pretty fast, and staying ahead really means adopting materials that are both efficient and eco-friendly. Take

Sichuan D&F Electric Co., Ltd., for example — they've been making electrical connection parts and insulation components since 2005, and they know how crucial it is to tweak their production methods to be more efficient while also caring for the environment. One material that's been catching on lately is Gpo-3 Plastic. It's loved for its excellent thermal insulation and durability. Industry reports say that using advanced plastics like Gpo-3 can boost energy efficiency in electrical products by up to 30%, plus it helps cut down on waste during manufacturing. As companies try to hit their operational goals and stay green at the same time, using Gpo-3 Plastic in production seems like a smart move — it’s a great way to stay competitive in the electrical industry while doing right by the planet.

Understanding Gpo-3 Plastic and Its Benefits for Production Processes

You know, GPO-3 plastic is this really interesting composite material that's gaining popularity, especially in industries like electronics and automotive. It’s well-loved because it has fantastic mechanical strength and can withstand heat pretty well. I read in a report by Smithers Pira that using advanced composites like GPO-3 can actually make products last longer and, at the same time, cut down their weight by up to 30%. Imagine that — lighter products that are more energy-efficient during transport and use. Plus, its low moisture absorption and great electrical insulation properties make it perfect for building those critical parts where performance and reliability really matter.

On top of that, GPO-3 isn’t just about performance — it also helps out with sustainability. For example, a study from the American Composites Manufacturers Association mentioned that switching to GPO-3 can cut down waste by over 20%. Thanks to its toughness, it reduces the need for repairs and replacements, which is a big plus for the environment. As industries are trying to be more eco-friendly, adding GPO-3 into production lines seems like a smart move. It’s a way to be more efficient without sacrificing quality, all while doing a bit better for our planet.

How to Optimize Your Production Process with Gpo-3 Plastic for Efficiency and Sustainability

| Aspect | Details |

|---|---|

| Material Composition | Gpo-3 is made from glass-reinforced epoxy laminate, providing high strength and durability. |

| Weight | Lightweight compared to traditional materials, enhancing handling and transportation efficiency. |

| Thermal Resistance | Excellent thermal stability, making it suitable for high-temperature applications. |

| Sustainability | Recyclable and produced with lower environmental impact compared to traditional plastics. |

| Cost Efficiency | Long lifespan and durability reduce the frequency of replacements, lowering overall costs. |

| Applications | Used in electrical, automotive, and aerospace industries for components requiring high performance. |

Identifying Key Areas for Efficiency Improvement with Gpo-3 Plastic

When it comes to improving production processes,

Gpo-3 plastic really shines as a versatile material that balances

efficiency with sustainability. Companies like Sichuan D&F Electric Co., Ltd., who focus on making

top-notch electrical connection parts and insulation components, know how important it is to spot areas

where things can get better. Industry reports suggest that Gpo-3 has excellent dielectric properties,

which makes it a fantastic choice for electrical use. Its ability to handle high temperatures and resist

moisture helps make electrical parts more reliable—meaning fewer breakdowns and less money spent on

repairs and maintenance.

If you're looking to get the most out of Gpo-3 plastic, it’s worth thinking about streamlining your

processes and better integrating your materials. Using advanced molding techniques can really speed

things up and cut down on waste. Plus, adopting a lean manufacturing approach can help you spot and

fix bottlenecks in your line before they become a bigger issue.

Tip: Make it a habit to keep an eye on your material suppliers.

Regularly checking their sustainability efforts and doing life cycle assessments can help ensure you're

sourcing Gpo-3 responsibly.

Choosing Gpo-3 isn't just about making products that work better—it also fits right into modern

sustainability goals. Cutting down energy use during production and opting for recyclable materials

can help your company reduce its environmental impact while staying competitive.

Tip: Consider training your team on the latest sustainability

practices. Encouraging a culture of ongoing learning and innovation really makes a difference over time.

Implementing Sustainable Practices in Production Using Gpo-3 Plastic

Nowadays, it’s pretty clear that adopting sustainable practices in manufacturing is more than just a trend — it’s kinda essential. One cool way to do this is by using Gpo-3 plastic, which, honestly, is a pretty versatile material thanks to its durability and lightweight nature. If companies incorporate Gpo-3 into their production lines, they can seriously cut down on unnecessary waste and save energy in the process. Plus, it makes products last longer, and better yet, it helps reduce the environmental footprint both during manufacturing and when the products eventually get disposed of.

To really get the most out of Gpo-3 plastic, though, businesses should take a step back and look at the bigger picture — basically, a holistic approach to sustainability. That might mean tweaking the production process to use this material more efficiently, or streamlining workflows so there’s less downtime and waste. It’s also a good idea to foster a mindset of sustainability within the company — things like recycling scrap parts or exploring circular economy ideas can make a big difference. When companies focus on these green practices, not only do they run more smoothly, but they’re also doing their part for a cleaner, greener planet. Win-win, right?

Evaluating Cost-Effectiveness of Gpo-3 Plastic in Production Workflow

When you're thinking about adding Gpo-3 plastic into your production process, it's super important to weigh whether it’s worth the cost. Gpo-3 is pretty awesome because it’s got solid mechanical strength and can resist the elements pretty well, which often means less downtime and fewer repairs. That kind of durability can really add up to savings, especially if your industry values long-lasting materials. By comparing your current expenses with what you'd spend on Gpo-3—and factoring in the potential savings—you can figure out if it’s really the smart move for your business.

A good tip is to do a full lifecycle analysis—look at everything from the upfront cost to ongoing operational expenses, and whatever you might save thanks to better efficiency down the line. Also, teaming up with your suppliers could help—see if they have bulk buying discounts or financing options. That way, you can keep costs down and keep your cash flow healthier.

And don’t forget, trying out Gpo-3 on a smaller scale first can be a game-changer. It’s like dipping your toes in the water before jumping all in—this trial run helps you see how it performs in a real-world setting without committing completely right away. As you gather data on how it works and what it costs, you’ll be able to make smarter choices that boost both your efficiency and sustainability in the long run.

Measuring and Analyzing Production Efficiency After Gpo-3 Integration

Adding Gpo-3 plastic into your production line can really boost efficiency and help out with sustainability. But, before you jump in, it’s a good idea to set some baseline numbers—like how long things usually take, how much waste you generate, and how much energy you're using. Once you've got those numbers, you can compare them after incorporating Gpo-3 to see just how much things have improved. It kind of gives you a clear picture of the gains and spots where you might still improve.

And here’s the thing: continuous monitoring is key. Using real-time data can help you spot issues right away, so you can tweak the process on the fly—saving resources and cutting down on downtime. Don’t forget to keep your team in the loop, too. Regular feedback from staff can give you insights that numbers alone might miss, which can lead to better practices and less waste over time.

In the end, focusing on measuring and analyzing your process not only makes things run smoother now but also supports your long-term goals for sustainability. It’s all about staying proactive and making smart adjustments along the way.

Market Trends and Performance Indicators for GPO-3 (UPGM203) Unsaturated Polyester Glass Mat Laminated Sheet in Composites Industry

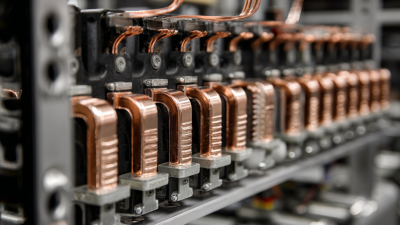

The composites industry has been witnessing a notable shift towards high-performance materials that cater to the evolving demands for durability and reliability. Among these materials, GPO-3 (UPGM203) unsaturated polyester glass mat laminated sheets have emerged as frontrunners, particularly due to their superior mechanical properties and excellent dielectric performance. According to recent market reports, the global demand for composites in various applications, especially in electrical insulation and industrial equipment, has propelled the growth of GPO-3 products, revealing a compound annual growth rate (CAGR) of over 6% projected over the next five years.

GPO-3 molded sheets, also referred to as DF370A, are manufactured from alkali-free glass mats that are seamlessly impregnated with unsaturated polyester resin. This process, which takes place under high temperatures and pressures, results in sheets that exhibit extraordinary machinability and strength. Furthermore, these laminated sheets are recognized for their outstanding arc resistance and proof tracking performance, making them suitable for applications in harsh environments. Industry certifications, including UL recognition and compliance with REACH and RoHS regulations, underscore their reliability and safety for various end-use applications.

Recent studies highlight that industries such as electrical and electronics, automotive, and aerospace are predominantly driving the demand for GPO-3 materials, as manufacturers seek components that not only meet regulatory standards but also enhance the longevity and efficacy of their products. As the trend towards eco-friendly and performance-oriented materials intensifies, GPO-3 unsaturated polyester laminates are set to play a pivotal role in the transformation of the composites landscape.

FAQS

: Gpo-3 plastic is a composite material recognized for its durability and lightweight properties. It is crucial for sustainable practices as it helps manufacturers reduce waste and energy consumption, enhancing product longevity while minimizing environmental impact.

Companies can implement sustainable practices by optimizing their production lines to efficiently use Gpo-3, streamlining processes to reduce downtime and waste, and fostering a culture of sustainability that promotes recycling and circular economy models.

Gpo-3 plastic offers superior mechanical properties and resistance to environmental factors, leading to reduced downtime and maintenance costs. This results in potential savings, making it a worthwhile investment for durability-focused industries.

When evaluating cost-effectiveness, businesses should conduct a lifecycle analysis that includes the initial investment, operational expenses, and potential savings from enhanced efficiency compared to traditional materials.

Companies can mitigate upfront costs by collaborating with suppliers that provide bulk purchasing options or financing plans, which can improve cash flow and reduce financial burden during the transition to Gpo-3 plastic.

Small-scale trials allow companies to understand Gpo-3's performance in real-world conditions without committing to a full-scale transition, enabling them to gather data to make informed decisions regarding efficiency and sustainability.

A holistic approach ensures that companies optimize their use of Gpo-3 plastic through efficient processes, encourages innovative practices, and supports a culture of sustainability, all of which strengthen operational efficiency and environmental commitment.

Recycling scrap materials and exploring circular economy models are key practices that contribute to sustainability, helping to minimize waste and promote the responsible use of resources in production processes.

Gpo-3 plastic is especially beneficial in industries where durability and longevity are critical, as its mechanical properties and resistance to environmental factors can significantly enhance product lifecycle.

By using Gpo-3 plastic, manufacturers can reduce the environmental impact associated with the production and disposal of goods, aligning their operations with broader sustainability goals for a greener future.

Conclusion

The article titled 'How to Boost Your Production with Gpo-3 Plastic for Better Efficiency and Sustainability' really highlights some pretty awesome benefits of using Gpo-3 Plastic in manufacturing. It kicks off by explaining what makes this material special—things like how it can make your production smoother and more eco-friendly. If you focus on areas like streamlining workflows or cutting down on waste, Gpo-3 Plastic can actually help simplify your operations quite a bit.

Plus, the article stresses how important it is to adopt sustainable practices in manufacturing, pointing out how Gpo-3 Plastic can be a real game-changer for eco-conscious production. It also digs into whether it's worth the investment financially—making sure that using Gpo-3 Plastic isn’t just good for the planet, but also makes sense on the bottom line. And, of course, it’s vital to keep track of how things improve after you start using it, so you can keep fine-tuning and pushing for even better results. Overall, Gpo-3 Plastic seems to have a solid role in helping manufacturers operate more efficiently and sustainably.

Related Posts

-

Exploring Unique Custom Molding Part Alternatives for Global Buyers

-

Unlocking the Advantages of Bare Copper Strip in Electrical Applications for Energy Efficiency

-

How to Achieve a Durable Finish with Epoxy Bus Coating Techniques

-

Solutions for Enhancing Electrical Efficiency with Silver Plated Copper Bus Bars

-

Global Market Insights: Projecting the Future of Best Epoxy Fiberglass Tubes by 2025

-

How to Choose the Best Tin Plated Copper Bus Bar for Your Electrical Needs