Power Electronics Busbar Tips for Efficient Design and Usage?

Table of Contents

- Power Electronics Busbar: Overview and Importance in Modern Applications

- Key Design Considerations for High-Efficiency Busbars

- Material Selection: Copper vs. Aluminum for Optimal Performance

- Thermal Management Strategies for Effective Busbar Operation

- Current Rating Calculations Based on Industry Standards

- Busbar Layout and Configuration for Minimizing Electromagnetic Interference

- Real-World Case Studies: Successful Implementation of Busbar Solutions

- Innovative Applications of GFRP Pultruded Electrical Insulation Profiles in Modern Electrical Engineering

- FAQS

- Conclusion

- Related Posts

The Power Electronics Busbar might not be something you think about all the time, but honestly, it plays a pretty big role in today’s electrical setups. Getting it designed right can really make a difference in how well everything runs. As energy efficiency becomes more and more important, engineers in this field are facing quite a few hurdles, no surprise there.

One of the tricky parts is dealing with heat — high currents tend to heat things up, and if you don’t manage that properly, you risk damaging the components. Choosing the right materials is key here. Copper is usually the go-to because it’s such a good conductor, but then again, we also have to keep an eye on the weight and cost.

Then there’s layout — how you organize everything really matters. A good design reduces resistance and keeps things running smoothly and reliably. You really need to think carefully about spacing and connections, because the tiniest mistake can cause a bunch of issues or inefficiencies. Sometimes, taking a fresh look at how things are currently done can reveal some easy wins for improvement. The world of Power Electronics Busbars is always changing, so paying attention to the details and staying creative is really the name of the game.

Power Electronics Busbar: Overview and Importance in Modern Applications

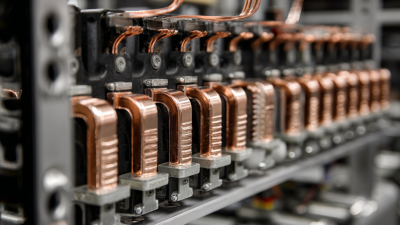

Power electronics busbars are critical components in modern electronic systems. They efficiently distribute power among various devices. Typically made from materials like copper or aluminum, these busbars minimize resistance. Their design impacts thermal management directly. Good design can enhance performance significantly. However, many overlook the importance of proper sizing. A busbar that is too small can lead to overheating.

In applications like electric vehicles and renewable energy, busbars bear heavy loads. Thus, they must be capable of handling high currents without degradation. Insufficient attention to this can lead to failures. Furthermore, the layout of busbars affects wiring complexity. A compact arrangement can simplify assembly but may cause overheating issues if not designed wisely.

Designing effective busbars requires balancing several factors. Engineers often grapple with trade-offs between size and conductivity. Choosing the right insulating materials can also complicate these choices. Improper insulation can lead to short circuits and fires. Reflecting on past designs can provide valuable insights for future projects. Adapting to these challenges is crucial in achieving efficiency and reliability.

Key Design Considerations for High-Efficiency Busbars

When designing efficient power electronics busbars, several key considerations are essential. Firstly, material selection is critical. Aluminum and copper are common choices, but each has pros and cons. Aluminum is lighter, but copper offers better conductivity. The choice will depend on the specific application requirements.

Additionally, the geometry of the busbar plays a significant role. Flat busbars can allow for better thermal dissipation. However, it’s vital to ensure that the busbar dimensions align with the electrical load specifications. If not, overheating can result, leading to failures. This requires careful thermal management strategies to avoid costly mistakes.

Finally, consider the connections. Poor or loose connections can introduce resistance, causing energy losses. Regular inspections are essential to identify potential issues. The design should account for future expansion. If not, the initial design could become a bottleneck as demand increases. Balancing efficiency and practicality often requires reflection and adjustments.

Material Selection: Copper vs. Aluminum for Optimal Performance

Material selection is crucial in power electronics busbar design. Copper and aluminum are two primary contenders. Copper offers higher conductivity, making it a popular choice. Its electrical conductivity is around 59 S/m. For high-performance applications, this can lead to lower resistive losses. However, copper is heavier and more expensive than aluminum.

On the other hand, aluminum, with a conductivity of 37 S/m, is lighter and cost-effective. It is widely used in applications where weight is a critical factor. Aluminum alloys can reduce susceptibility to corrosion. Yet, one must consider the trade-off in performance due to its lower conductivity. The choice among these materials is not straightforward.

Manufacturers must evaluate the application's specific requirements. Kicking costs versus performance can lead to potential long-term inefficiencies. Some reports suggest aluminum can be as efficient as copper when properly designed. The design must reflect the operating conditions to optimize performance. Balancing price, weight, and conductivity is essential for effective busbar application. Ultimately, the decision should incorporate thorough analysis and reflection on future needs.

Power Electronics Busbar Material Comparison: Copper vs. Aluminum

Thermal Management Strategies for Effective Busbar Operation

Thermal management is crucial for the effective operation of busbars. As power densities increase, the heat generated by busbars can lead to failures and reduced performance. A 2021 industry report indicated that 30% of electronic failures stem from thermal issues. Proper heat dissipation methods are essential for reliability.

One effective strategy is implementing cooling techniques. Using heat sinks or thermal pads can significantly reduce operating temperatures. A poorly designed thermal interface can elevate temperatures by 15°C or more. Conducting regular thermal simulations can identify hotspots and optimize design. These simulations help ensure proper airflow and material selection.

Even with these strategies, some systems may still struggle. Inadequate cooling can lead to localized overheating. This issue often arises in tightly packed designs. Manufacturers must address these challenges proactively. Real-world testing is important. It helps refine designs and improve thermal management efforts. Balancing efficiency and thermal control remains a complex task.

Current Rating Calculations Based on Industry Standards

Calculating current ratings for power electronics busbars is essential. Industry standards provide a framework to follow. For instance, IEEE 519 outlines harmonic distortion limits, which can affect current carrying capacity. Employing these standards ensures safe and efficient operation.

When determining ratings, factors such as ambient temperature, insulation type, and installation method should be considered. According to IEC 60947, derating is recommended when temperatures exceed 30°C. Many designs fail to account for such variables, risking overheating or system failure. Regular reviews of these conditions can help minimize failures.

Documentation often references the importance of proper engineering practices. However, practitioners must also recognize potential pitfalls. Incomplete assessments can lead to inaccuracies. A 2022 survey revealed that 35% of engineers overlook environmental factors impacting busbar performance. Striving for perfection in current rating calculations is crucial for reliability. Each design decision matters.

Busbar Layout and Configuration for Minimizing Electromagnetic Interference

When designing a busbar layout, minimizing electromagnetic interference (EMI) is crucial. Start by arranging busbars in parallel lines. This can help reduce the loop area, which is a primary contributor to EMI. Place sensitive components away from high-current paths. A thoughtful arrangement significantly reduces interference.

Configuration matters as well. Thick busbars can carry larger currents, but they also have higher potential for EMI. Consider using shielding techniques. Encasing busbars in conductive materials can help block interference. However, ensure that grounding is done correctly, or it may lead to other issues.

Lastly, reviewing the layout periodically can uncover hidden problems. Sometimes what looks good on paper may not perform well in practice. Test under real conditions to find the best configuration. Small adjustments can lead to better performance and lower EMI. Document changes to learn from mistakes.

Real-World Case Studies: Successful Implementation of Busbar Solutions

The implementation of busbar solutions in power electronics has shown impressive results in various industries. A case study in renewable energy highlighted a solar farm using aluminum busbars. This resulted in a 20% reduction in electrical losses compared to traditional wiring. Such efficiency improvements can make a significant difference in large-scale operations.

In the automotive sector, one manufacturer opted for copper busbars to enhance the performance of electric vehicle charging stations. They reported a 15% increase in charging speed. However, the initial costs and long-term maintenance of busbar systems can be a concern. Data from the Power Electronics Association indicates that 25% of installations face issues related to thermal management.

Real-world implementation often reveals unexpected challenges. One notable case involved a data center that underestimated heat generation from their busbars. This led to overheating, forcing an emergency redesign. Learning from these experiences is vital for future designs. Proper simulations and stress testing during the design phase can mitigate these risks effectively.

Innovative Applications of GFRP Pultruded Electrical Insulation Profiles in Modern Electrical Engineering

The innovative applications of Glass Fiber Reinforced Polymer (GFRP) pultruded electrical insulation profiles have significantly advanced modern electrical engineering. These profiles, crafted from a composite of glass fiber yarn and polyester resin paste, exhibit exceptional dielectric properties and mechanical strength, making them ideal for various electrical components. Their unique formulation allows for superior performance in environments where electrical insulation is crucial, outperforming traditional materials in both efficiency and durability.

One of the primary advantages of pultruded insulation profiles is their customizable length, providing flexibility that molded counterparts cannot offer. This capability enables engineers to tailor the profiles precisely to meet the specific requirements of their projects, whether for support beams or other insulation structural applications. This adaptability not only streamlines the manufacturing process but also enhances the overall design and implementation strategies in electrical systems, leading to more robust and reliable installations. As electrical engineering continues to evolve, leveraging the strengths of pultruded insulation profiles will be essential for innovative and effective solutions.

FAQS

: Common recyclables include paper, cardboard, glass, and certain plastics. Check local guidelines for specifics.

Clean and dry recyclables before placing them in bins. Remove food residue to prevent contamination.

Contaminated items can spoil entire batches. Improper recycling may lead to increased waste.

Plastic bags often cannot be recycled curbside. Many stores have dedicated drop-off locations for them.

Guidelines can change frequently. It’s wise to check them every few months or when you’re unsure.

When in doubt, it's better to throw the item away. This helps prevent contamination in the recycling stream.

Recycling reduces landfill waste and conserves resources. It can lower pollution levels and save energy too.

Share information with friends and family. Use social media to spread awareness about proper recycling practices.

Many recyclables are derived from natural resources, but not all. Some are synthetic or blended materials.

Limited resources and lack of programs can hinder recycling efforts. Awareness and education are crucial for improvement.

Conclusion

Power Electronics Busbar plays a crucial role in the efficiency and performance of modern electrical systems. This article provides a comprehensive overview of the importance of busbars in various applications, emphasizing key design considerations that enhance efficiency. It delves into the material selection between copper and aluminum, analyzing their respective benefits for optimal performance.

Moreover, effective thermal management strategies are discussed to ensure the reliable operation of busbars, along with current rating calculations based on industry standards. The layout and configuration of busbars are also highlighted, particularly in minimizing electromagnetic interference. Finally, real-world case studies illustrate the successful implementation of innovative busbar solutions, showcasing their impact on efficiency and reliability in power electronics.

Related Posts

-

Unlocking Efficiency: How Water Cooled Cold Plates Revolutionize Thermal Management in Electronics

-

What is Electric Power Copper Bus Bar and Its Advantages for Electrical Systems

-

What is High Temperature Insulation Board and Its Applications?

-

Solutions for Enhancing Electrical Efficiency with Silver Plated Copper Bus Bars

-

Global Market Insights: Projecting the Future of Best Epoxy Fiberglass Tubes by 2025

-

7 Essential Tips for Mastering Electrical Insulator Machining Efficiency