Understanding the Advantages of Rigid Copper Busbars in Modern Electrical Systems

Table of Contents

- Benefits of Rigid Copper Busbars in Electrical Systems

- Key Properties of Rigid Copper Busbars that Enhance Performance

- Comparison of Rigid Copper Busbars with Alternative Conductors

- Applications of Rigid Copper Busbars in Modern Electrical Infrastructure

- Cost-Effectiveness and Longevity of Rigid Copper Busbars

- Challenges and Solutions in Implementing Rigid Copper Busbars

- Optimizing Electrical Efficiency: Trends and Innovations in Custom Rigid Copper or Aluminum Bus Bars Based on Industry Data Insights

- FAQS

- Conclusion

- Related Posts

Rigid copper busbars have really become a key player in today’s electrical systems. They come with a bunch of perks that boost both efficiency and reliability—something pretty important no matter what kind of application you're dealing with. The International Electrotechnical Commission (IEC) actually predicts that worldwide demand for these busbars will shoot up, mainly because industries and commercial sectors are craving more effective ways to distribute power. Rigid copper busbars are especially appreciated for their excellent conductivity, ability to handle heat well, and tough mechanical strength. That makes them perfect for high-load scenarios.

Rigid copper busbars have really become a key player in today’s electrical systems. They come with a bunch of perks that boost both efficiency and reliability—something pretty important no matter what kind of application you're dealing with. The International Electrotechnical Commission (IEC) actually predicts that worldwide demand for these busbars will shoot up, mainly because industries and commercial sectors are craving more effective ways to distribute power. Rigid copper busbars are especially appreciated for their excellent conductivity, ability to handle heat well, and tough mechanical strength. That makes them perfect for high-load scenarios.

On the manufacturing side, Sichuan D&F Electric Co., Ltd.—a company that’s been around since 2005—really knows their stuff. They focus on making top-quality electrical connectors and structural insulation parts. Their expertise in producing durable, efficient copper busbars lines up perfectly with the industry’s move toward more reliable and sustainable electrical systems. All in all, they’ve grown into a trusted name in this growing market.

Benefits of Rigid Copper Busbars in Electrical Systems

Rigid copper busbars are really important in today’s electrical setups, and they come with quite a few benefits that boost both efficiency and reliability. One big plus of using solid copper is its awesome electrical conductivity, which basically means less energy gets lost during power transmission. That helps the system run smoothly at high currents without overheating. Plus, copper naturally resists corrosion, so it stays durable and lasts a long time—kind of a win for your wallet over time.

Another thing I like about rigid copper busbars is how easy they are to install and keep up with. Their sturdy build ensures a reliable connection, which cuts down on chances of loose wires and electrical issues. That’s not only safer but also means less downtime when doing maintenance—definitely a plus for keeping things running seamlessly. Oh, and the compact design helps save space in electrical panels, giving you more flexibility to set things up just how you want them in different projects.

Understanding the Advantages of Rigid Copper Busbars in Modern Electrical Systems

| Advantage | Description | Application Areas |

|---|---|---|

| High Conductivity | Superior electrical conductivity ensures minimal energy loss. | Power distribution systems, renewable energy installations. |

| Durability | Robust construction withstands harsh environmental conditions. | Industrial environments, outdoor substations. |

| Design Flexibility | Customizable sizes and shapes for specific system requirements. | Data centers, custom electrical installations. |

| Thermal Performance | Efficient heat dissipation reduces overheating risks. | Electrical panels, high-load areas. |

| Low Maintenance | Requires minimal upkeep, resulting in lower long-term costs. | Commercial buildings, manufacturing plants. |

Key Properties of Rigid Copper Busbars that Enhance Performance

Rigid copper busbars are pretty much essential in today's electrical setups, mainly because they have great conductivity and are pretty strong physically. One thing I should point out is how copper's excellent electrical conductivity really helps keep energy losses to a minimum — it's a big deal, especially for stuff like power grids or renewable energy projects where every bit of efficiency counts.

Another thing I like about these busbars is how tough they are. They’re built to handle tough conditions — high temperatures, exposure to things that might cause corrosion, you name it. This sturdy design doesn’t just make them last longer; it also means you don’t have to worry about replacing them all the time, which definitely saves some cash in the long run. Plus, because they're rigid, they’re generally pretty easy to install and fit right into existing electrical setups, which is a big plus for a lot of projects.

Comparison of Rigid Copper Busbars with Alternative Conductors

You know, rigid copper busbars are pretty much a staple in today’s electrical setups — especially when you compare them to things like aluminum or more flexible busbars. According to a report from the International Copper Association, copper’s conductivity is about 61% better than aluminum’s, which really makes a difference. It means less energy lost as heat and better overall efficiency. Because of this, engineers can often make the busbars thinner without sacrificing performance, making copper a really popular choice for tight, high-density installations.

On top of that, the mechanical side of things is pretty impressive too. Copper is strong, so it can handle higher currents and thermal changes without breaking a sweat. That’s a huge plus in critical systems where reliability really matters. Industry standards—like those from IEEE—say that copper helps dissipate heat about 25% more efficiently, which helps extend how long the electrical components last. All of this adds up to copper being especially useful in demanding environments, like data centers and industrial power setups, where durability and top performance are non-negotiable.

Applications of Rigid Copper Busbars in Modern Electrical Infrastructure

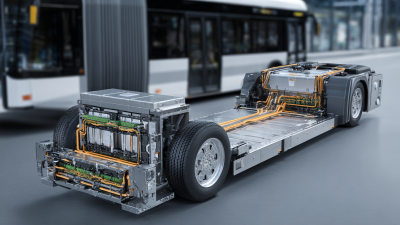

Rigid copper busbars are becoming pretty essential in today's electrical setups, mainly because they’re such high performers in terms of conductivity, toughness, and versatility. You’ll find these busbars everywhere, from power distribution grids to large industrial plants—really, they’re a key part of making sure energy gets where it needs to go efficiently. And with the growing demand for more energy-efficient systems, the global busbar market is really on the rise. Interestingly, reports show that the Asia Pacific region is expected to see some big growth, driven by the push for safer, more reliable power distribution solutions.

Specifically, these rigid copper busbars are super important in big-scale electrical systems—think substations or huge industrial power setups. They’re great at handling high currents and providing solid, secure connections, which is exactly what’s needed in those kinds of demanding environments. As electrical systems continue to modernize, it looks like more folks will prefer these copper busbars over others, like aluminum ones, mainly because they tend to offer better stability and less resistance. That’s especially crucial when we’re talking about saving energy and cutting down on power losses—things that matter a lot in today’s world of greener, more efficient power!

Cost-Effectiveness and Longevity of Rigid Copper Busbars

Rigid copper busbars are pretty much a key part of modern electrical setups. They offer some serious benefits, especially when it comes to saving money and lasting a long time. Unlike the usual wiring, these busbars give a lower-resistance path for electricity, which means better energy efficiency and lower operating costs. Plus, they’re built tough, so you don’t have to worry about replacing or fixing them all the time. Over the long run, that saves a lot on maintenance too.

Here at Sichuan D&F Electric Co., Ltd., we’ve been around since 2005, making us a trusted name when it comes to electrical connection parts and insulation components. We specialize in high-quality rigid copper busbars that meet the rising demand for reliable, cost-effective electrical solutions. By using advanced manufacturing methods and sticking to strict quality standards, we ensure our busbars not only distribute energy efficiently but also stand the test of time in all kinds of industrial settings.

Challenges and Solutions in Implementing Rigid Copper Busbars

Using solid copper busbars in modern electrical setups definitely has its perks—think better conductivity, durability, and a more compact design. But, of course, it’s not all smooth sailing. There are some real challenges that engineers and designers need to keep in mind when they’re trying to incorporate these components. For starters, copper is pretty heavy, which can make the installation process a bit more complicated and might require stronger support structures. On top of that, making sure the busbars are properly insulated and dealing with thermal expansion issues is super important—if you don’t, you risk system failures down the line, especially when conditions change a lot.

**Tip:** When you’re planning to install rigid copper busbars, it’s a good idea to look into lightweight support materials. It helps cut down on the overall weight and makes the whole setup a lot easier to handle.

Another thing to keep in mind is the cost. Rigid copper busbars tend to be more expensive upfront compared to other materials. While they usually pay off in the long run thanks to their benefits, the initial price can definitely be a barrier for some projects. And don’t forget about making sure they’re compatible with your existing infrastructure—retrofits might mean extra modifications and added hassles.

**Tip:** Do a solid cost-benefit analysis early on to show how the long-term gains outweigh the initial expenses. Also, exploring options like financing or phased installation can really help manage cash flow concerns and make things more manageable overall.

Optimizing Electrical Efficiency: Trends and Innovations in Custom Rigid Copper or Aluminum Bus Bars Based on Industry Data Insights

In the quest for optimizing electrical efficiency, the importance of custom rigid copper or aluminum bus bars cannot be overstated. These critical components serve as the backbone of electrical systems, facilitating the safe and efficient distribution of current. According to industry data insights, the trend towards higher efficiency is driving innovations in the design and production of these bus bars. Sichuan Myway Technology Co., Ltd., with over 17 years of CNC machining experience, stands at the forefront of this trend by offering high-quality copper bus bars tailored to meet specific user requirements.

CNC machining plays a pivotal role in the fabrication of rigid bus bars from both copper and aluminum sheets. This process ensures precision and consistency, leading to superior products that can withstand the demands of modern electrical systems. The design of these bus bars, often in long rectangular shapes with rounded edges, is specifically engineered to minimize risks such as point discharge. By selecting rounded copper bars, users enhance the safety and reliability of their electrical connections, making them ideally suited for various applications in commercial and industrial settings. As industries continue to evolve, the focus on optimizing electrical efficiency will drive further innovations in bus bar technology, paving the way for more sustainable electrical solutions.

FAQS

: Rigid copper busbars are used for power distribution systems, renewable energy applications, and large-scale electrical installations like substations and industrial power setups due to their high conductivity and durability.

Copper provides excellent electrical conductivity, ensuring minimal energy loss during transmission, which is crucial for efficient operation in electrical systems.

They provide a lower resistance pathway for electrical currents, leading to improved energy efficiency and reduced operational costs, along with minimizing maintenance and replacement needs.

Yes, rigid copper busbars are designed to withstand high temperatures and corrosive elements, making them durable and suitable for various industrial applications.

The rigid structure of copper busbars allows for easy installation and integration into existing electrical frameworks.

The demand stems from the need for efficient power distribution solutions that prioritize safety and reliability, which is leading to substantial growth in the busbar market.

Rigid copper busbars provide greater stability and lower resistance, making them particularly suitable for applications where energy efficiency and power loss reduction are critical.

Sichuan D&F Electric Co., Ltd. specializes in the manufacturing of high-quality electrical connection components and rigid copper busbars, meeting the growing demand for durable and economical electrical solutions.

Conclusion

Rigid copper busbars are pretty essential in today’s electrical setups. They offer a bunch of benefits, especially when it comes to improving performance and efficiency. These busbars are known for their excellent conductivity, durability, and strength, which often makes them a better pick compared to other types of conductors. You’ll find them everywhere—from different sectors of modern electrical infrastructure—because they provide reliable connections and can handle high currents with ease.

Plus, they’re quite cost-effective and tend to last a really long time. That means they’re a solid, long-term solution for electrical connections. Of course, setting them up isn’t always without challenges, but don’t worry—there are plenty of effective ways to sort out any issues that pop up. As a manufacturer and supplier, Sichuan D&F Electric Co., Ltd. is dedicated to delivering top-quality rigid copper busbars, supporting the creation of sturdy and reliable electrical systems for all kinds of applications.

Related Posts

-

The Future of Innovation in the Copper Aluminum Busbar Market

-

7 Tips for Choosing the Right Copper Bus Bar Manufacturer in Spain

-

7 Essential Tips for Mastering Electrical Insulator Machining Efficiency

-

The Importance of Transformer Insulation Sheets in Modern Electrical Engineering

-

Exploring Innovations in Laminates For Class F at the 138th China Import and Export Fair 2025

-

Identifying Challenges with Electric Vehicle Busbar Innovations