The Ultimate Checklist to Choosing the Best Copper Bus Bar for Global Procurement

Table of Contents

- Key Advantages of Using Copper Bus Bars in Electrical Systems

- Comparative Analysis: Copper vs. Other Bus Bar Materials

- Impact of Conductivity on Efficiency and Performance

- Longevity and Durability Benefits of Copper Bus Bars

- Cost-Effectiveness: Investment and Return on Copper Bus Bars

- Sustainability and Environmental Benefits of Copper Usage in Procurement

- Unlocking the Benefits of Custom Copper Foil and Braid Flexible Bus Bars for Enhanced Electrical Performance

- FAQS

- Related Posts

You know, in the fast-changing world of electrical stuff, picking the right copper bus bar isn’t just a small detail — it’s actually super important for keeping power systems running smoothly and reliably. If you look at the global market, it’s expected to hit around 24.6 billion USD by 2025. That growth is mostly because everyone’s really into energy-efficient systems and sustainable tech these days. So, manufacturers really need to focus on quality and performance when they’re choosing what to buy.

Sichuan D&F Electric Co., Ltd., which’s been around since 2005, has earned a solid reputation when it comes to electrical connection parts. They’ve got a wide range of Copper Bus Bars for sale that meet tough industry standards. As electrical setups get a bit more complicated, knowing the ins and outs — like technical specs and current trends — about copper bus bars can actually help businesses make smarter decisions. That way, they can boost efficiency and reliability, and really take advantage of all the new opportunities popping up in this growing market.

Key Advantages of Using Copper Bus Bars in Electrical Systems

Copper bus bars play a pretty crucial role in electrical systems—they're the backbone that keeps things connected smoothly and helps distribute current effectively. Their high electrical conductivity, around 59.6 S/m, generally beats out materials like aluminum, which means less energy lost and better performance across many industrial setups. Especially in power distribution, copper bus bars can handle higher current loads without heating up too much, making them a smart pick for keeping everything running efficiently and safely.

When you're picking out the right copper bus bars for your project, here are a few things to keep in mind: First off, think about where you'll be using them—if it's a tough, corrosive environment, go for ones with protective coatings to help them last longer. Next, consider how good their thermal conductivity needs to be—proper heat management is key to stopping them from overheating. And last but not least, it pays to go with trusted suppliers like Sichuan D&F Electric Co., Ltd. They've been around since 2005 and specialize in top-notch electrical connection parts and structural components. Plus, they’re known for delivering products that meet all the industry standards, so you can count on quality.

Splurging a bit on quality copper bus bars is a smart move. It not only keeps your systems safe and compliant, but it also boosts reliability and efficiency in the long run—saving you money down the line, no doubt.

The Advantages of Using Copper Bus Bars in Electrical Systems

Comparative Analysis: Copper vs. Other Bus Bar Materials

When you're trying to pick the best copper bus bar for global procurement, it's really important to do a side-by-side comparison between copper and other materials. Honestly, copper tends to stand out because of its incredible conductivity—around 59.6 million Siemens per meter, to be precise. That’s a big jump compared to aluminum, which usually clocks in at about 37.7 million S/m. Basically, this means copper bus bars can carry higher currents and just perform better overall in electrical systems. Plus, copper's resistance to corrosion makes it a real long-term winner, especially for applications where durability counts.

Oh, and here’s a quick tip: When you’re evaluating different materials for bus bars, don’t just think about the upfront cost. It’s also worth considering long-term reliability and efficiency. Sure, copper might be pricier at the start, but it can save you money down the line thanks to its toughness and lower energy losses.

Oh, and here’s a quick tip: When you’re evaluating different materials for bus bars, don’t just think about the upfront cost. It’s also worth considering long-term reliability and efficiency. Sure, copper might be pricier at the start, but it can save you money down the line thanks to its toughness and lower energy losses.

Another thing to keep in mind is understanding ampacity—that’s basically how much current a bus bar can handle without overheating. The maximum current depends a lot on the bar's cross-sectional area. So, if you've got a, say, rectangular copper bus bar rated for higher currents, that can be a total game-changer, especially in heavy-duty power setups. Just make sure to stick to industry standards like the National Electric Code (NEC) to stay compliant and keep everything safe.

And one more tip: consider using detailed analytical methods—like those based on partial inductance theory—to calculate the impedance of bus ducts. It might sound technical, but it’s worth it for really optimizing your system’s performance and reliability.

Impact of Conductivity on Efficiency and Performance

When you're out there choosing a copper bus bar for global sourcing, one thing you really can't overlook is its conductivity. Copper’s kinda famous for being an excellent electrical conductor, and that’s a big deal because it directly affects how well your electrical systems perform overall. If the bus bar has high conductivity, it means less resistance — which translates to less energy wasted and a more reliable system. That’s especially important in heavy-duty setups where even tiny differences in conductivity can lead to significant energy losses and higher operational costs.

When you're out there choosing a copper bus bar for global sourcing, one thing you really can't overlook is its conductivity. Copper’s kinda famous for being an excellent electrical conductor, and that’s a big deal because it directly affects how well your electrical systems perform overall. If the bus bar has high conductivity, it means less resistance — which translates to less energy wasted and a more reliable system. That’s especially important in heavy-duty setups where even tiny differences in conductivity can lead to significant energy losses and higher operational costs.

But here’s the thing — conductivity isn’t just about saving energy. A bus bar with better conductivity can handle larger currents without breaking a sweat, which is a must in industrial or commercial environments. Not only does that extend the lifespan of your electrical setup, but it also helps keep things safe by reducing the risk of overheating or sudden failures. So, when you’re comparing different copper bus bars, make sure to look at the copper’s purity, how they’re made, and all those little details that influence how well it conducts. The goal is to pick something that’s really suited to your specific needs and setup.

Longevity and Durability Benefits of Copper Bus Bars

When you're choosing a copper bus bar for global procurement, one of the most important things to consider is how long it’ll last and how tough it is.

Copper’s a pretty awesome material—it’s highly conductive and resistant to corrosion, which means you won’t have to worry too much about maintenance,

and it helps keep your system running smoothly. Industry reports actually show that, if everything’s perfect, copper bus bars can last over 50 years!

That's a solid investment really pays off in the long run.

Tip: When you're shopping around, make sure the copper used is of high purity—at least 99.9%.

That way, you get the best conductivity and fewer energy losses. It might seem like a small detail, but it really helps lower operational costs and boosts overall efficiency.

Plus, copper is super strong and able to handle tough environmental conditions. According to the International Copper Association,

the tensile strength of copper lets it take on heavier loads without bending or deforming—something aluminum just can't quite do.

This durability means fewer failures, especially in harsh industrial environments.

Tip: Don’t forget to verify that the bus bars meet standards like IEEE, IEC, or UL.

Trust me, making sure they’re certified for performance and safety is key to keeping your electrical setup reliable and safe over time.

Cost-Effectiveness: Investment and Return on Copper Bus Bars

When you're choosing copper bus bars for global procurement, one thing you really can't ignore is the cost. Copper bus bars are key for efficient energy distribution — no doubt about that — but getting a handle on the investment and what kind of payoff you'll get in the long run is super important if you want to make smart decisions. Sure, those high upfront costs might make some people hesitate, but often, the benefits down the road—like needing less maintenance and better conductivity—make it worth it. So, it’s really about finding that sweet spot: matching your business’s energy needs with what you’re willing to spend.

A good tip is to shop around and compare multiple suppliers. Look at both the quality of the material and how they make their bus bars. Going with certified suppliers usually means you’re getting a better product, which can save you money on replacements later. Also, don’t forget about the entire product life cycle—spending a little more on something durable can save you a lot in the long run.

And here’s another thing: copper is pretty valuable when it comes to recycling. When your company eventually swaps out the bus bars, you can sell the recycled copper and recoup some of your costs. Knowing the whole life cycle—from purchase to resale—can really boost the overall value of your investment. At the end of the day, balancing upfront costs with potential savings down the road is key to making a smart, strategic call on procurement.

The Ultimate Checklist to Choosing the Best Copper Bus Bar for Global Procurement - Cost-Effectiveness: Investment and Return on Copper Bus Bars

| Criteria | Selection Factor | Cost Effectiveness | Return on Investment (ROI) |

|---|---|---|---|

| Material Quality | High conductivity, low impurity | Higher initial cost but reduces energy loss | Medium to high ROI due to energy savings |

| Thickness | Standard sizes available | Custom thickness may raise costs | Higher thickness may increase ROI through durability |

| Finish Type | Bare, tin-plated, or brass | Tin plating increases cost, reducing corrosion | Longer lifespan enhances ROI |

| Weight | Measured in kg | Heavier bars cost more in shipping | Lower shipping expenses can improve ROI |

| Application Type | Industrial, Commercial | Specialization may affect cost | Application-specific bars may lead to higher efficiency, improving ROI |

Sustainability and Environmental Benefits of Copper Usage in Procurement

When you look at global sourcing these days, it’s pretty clear that understanding the sustainability and environmental perks of using copper really matters. I mean, copper’s got some pretty awesome qualities—like its high conductivity and long-lasting durability—that make it a must-have across different industries. These days, companies are making an effort to be more eco-conscious in how they source materials. Not only does this help them save energy, but it also cuts down on waste, which is such a big deal, especially with the rise of electronic waste and all the buzz around AI hardware. If organizations adopt smarter, more sustainable sourcing strategies, they can actually shrink their environmental impact while making their supply chains more resilient and reliable.

Plus, things like recycling chips and managing raw materials responsibly really push the sustainability agenda forward. As more industries look into greener options, a lot of effort is going into responsible mining and embracing circular economy principles. You see this in partnerships aimed at making mining more environmentally friendly and in sectors pushing to use more sustainable materials. With the right procurement approaches, businesses can do their part for a greener future—tapping into copper's benefits while also being good stewards of the environment. It’s about balancing business needs with caring for the planet, you know?

Unlocking the Benefits of Custom Copper Foil and Braid Flexible Bus Bars for Enhanced Electrical Performance

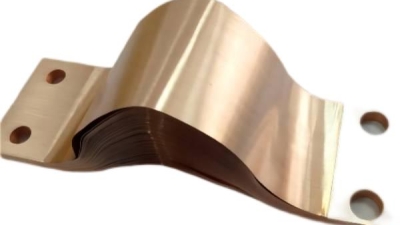

In today’s rapidly evolving electrical landscape, the demand for enhanced performance and reliability has led to significant innovations in bus bar technology. The use of custom copper foil and braid flexible bus bars has emerged as a game-changer, offering substantial benefits that address common electrical challenges. According to industry reports, these flexible bus bars not only allow for effective compensation of thermal expansion and mechanical vibration but also contribute to improved efficiency in electrical connections.

Flexible bus bars, which include copper foil, copper strip, copper braid, and copper stranded wire variants, are designed to accommodate the deformation that bus bars experience due to temperature fluctuations. This feature is particularly crucial in applications such as battery packs, where maintaining optimal performance is paramount. A study by the International Electrotechnical Commission highlights that utilizing flexible connectors can reduce energy losses by up to 5% compared to rigid connections, emphasizing their value in maximizing electrical efficiency.

Furthermore, the versatility of these bus bars in diverse environments enhances safety and operational longevity. As noted in a recent report by the Electric Power Research Institute, custom flexible bus bars can significantly mitigate the risks associated with electrical fluctuations, leading to fewer system failures and lower maintenance costs. In the quest for superior electrical performance, the integration of custom copper foil and braid flexible bus bars represents a key advancement in ensuring reliable and efficient power distribution.

FAQS

: Copper bus bars offer longevity and durability due to their high conductivity and resistance to corrosion, which reduces maintenance costs and enhances system reliability. They have a lifespan of over 50 years under optimal conditions.

To maximize conductivity and minimize energy losses, it's essential to select bus bars made from high purity copper (at least 99.9% purity).

Copper bus bars exhibit superior mechanical strength and tensile strength, allowing them to endure higher loads without deformation, making them ideal for harsh industrial environments.

Copper bus bars should comply with performance and safety standards such as IEEE, IEC, or UL to ensure long-term reliability and safety in electrical installations.

Yes, while copper bus bars may have a higher initial cost, their long-term benefits like reduced maintenance costs and superior conductivity often justify the investment.

Companies should compare multiple suppliers, consider material quality and manufacturing processes, and evaluate life cycle costs to determine the best balance between price and performance.

Yes, copper has a high resale value, allowing companies to recover part of their investment when they eventually replace the bus bars.

Businesses should analyze their specific energy needs, potential savings, the initial and long-term costs, and any recycling options to enhance the overall economic value of their investment.