The Ultimate Guide to Understanding Smc Sheets and Their Applications in Modern Industries

Table of Contents

- Understanding the Basics of SMC Sheets and Their Composition

- The Versatility of SMC Sheets in Various Industrial Applications

- Comparative Advantages of Using SMC Sheets Over Traditional Materials

- Innovative Technologies Driving the Use of SMC Sheets

- Future Trends in SMC Sheet Applications Across Industries

- Exploring the Versatility and Applications of PIGC301 Polyimide Glass Cloth Rigid Laminated Sheets in Modern Industries

- FAQS

- Conclusion

- Related Posts

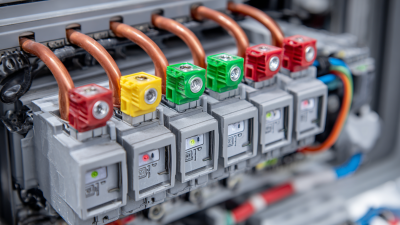

Nowadays, with how fast the industrial world is changing, it’s more important than ever to really get a handle on the materials fueling all this innovation. One material that's been catching a lot of attention lately is Smc Sheets—they're pretty much becoming a go-to because of how versatile they are across different industries. In this guide, I’ll walk you through what makes Smc Sheets special, their advantages, and how they're being used in a bunch of different ways. It’s pretty amazing how they’re helping modern industries keep up with demands for durability and efficiency. By the way, Sichuan D&F Electric Co., Ltd., a company that’s been around since 2005 and based in Deyang’s Jinshan industrial park, is really pushing the envelope with these sheets. They’ve been using them to make all sorts of electrical connection parts and insulation components. It’s exciting to see how Smc Sheets are changing the game in manufacturing and what they could mean for the industries of the future. Trust me, it’s worth taking a closer look at how they’re shaping up the industry scene right now.

Understanding the Basics of SMC Sheets and Their Composition

You know, SMC sheets—also called Sheet Molding Compounds—are pretty versatile materials that you often see in all sorts of modern industries. Basically, they’re made from a mix of unsaturated polyester resin, fiberglass, and a few other additives. These ingredients are blended together to give the sheets better strength and heat resistance. The resin acts like a glue holding everything together, while the fiberglass provides reinforcement, which keeps the sheet lightweight but super tough. Thanks to this combo, SMC sheets can handle really high temperatures and pressure, making them perfect for a bunch of different uses.

On top of their strong mechanical properties, SMC sheets are also great because they resist corrosion like a champ and are pretty easy to shape into complex forms. That makes them super valuable in sectors like automotive, electrical, and construction—areas where parts need to perform well and last a long time. Plus, being able to create detailed designs while still keeping their structure intact gives SMC an edge over traditional materials like metal or thermoplastics. As industries keep evolving, I think we’ll see even more applications for SMC sheets, highlighting just how important they are becoming in modern manufacturing—no doubt about it.

The Ultimate Guide to Understanding Smc Sheets and Their Applications in Modern Industries

| Property | Value | Applications |

|---|---|---|

| Density | 1.6-2.0 g/cm³ | Automotive parts, electrical components |

| Thermal Conductivity | 0.1-0.3 W/m·K | Heat sinks, electrical insulators |

| Flexural Strength | 100-200 MPa | Structural components, enclosures |

| Impact Resistance | High | Protective casings, housings |

| Chemical Resistance | Excellent | Corrosion-resistant applications |

| Manufacturing Process | Compression Molding | Complex shapes, mass production |

The Versatility of SMC Sheets in Various Industrial Applications

You know, SMC sheets—also called Sheet Molding Compounds—have really made a name for themselves across a bunch of modern industries because of how versatile they are. These composite materials, usually made from unsaturated polyester resin, fiber reinforcements, and fillers, can be shaped into pretty complex forms, which opens up tons of possibilities for different uses. Take the automotive world, for example—SMC sheets are often used to make lightweight body panels. That means cars can be more fuel-efficient without sacrificing safety. Plus, their resistance to heat, chemicals, and their insulating properties give manufacturers a real edge when it comes to making cars that last longer and perform better.

But it’s not just cars—construction folks are into SMC sheets too. They’re used to build things like panels and roofing materials because they’re tough and easy to work with. And the electrical and aerospace industries? They love them as well. The fact that SMC sheets are lightweight and insulating makes it easier to produce high-quality components that need to meet strict safety and performance standards. The growing push for more sustainable and efficient materials just highlights how important SMC sheets are becoming across these fields. All in all, they’re a pretty big deal when it comes to modern, innovative manufacturing.

Comparative Advantages of Using SMC Sheets Over Traditional Materials

Have you noticed how SMC (Sheet Molding Compound) sheets are really starting to gain popularity across different modern industries? Honestly, it’s pretty exciting because they have some pretty neat properties that give them a big edge over traditional stuff like metal, wood, or plastics. One of the biggest perks? Their incredible strength for such a lightweight material. I came across the 2023 Global Composites Market Report, and it mentioned that using SMC in cars can cut down weight by up to 30%. That’s a game-changer because it means better fuel economy and less pollution—definitely a big win for making transportation more eco-friendly.

Besides being light, SMC sheets are also super resistant to rust and last way longer in harsh conditions, which means less maintenance and more bang for your buck. There’s even a study from the Composite Materials Handbook that says SMC can last up to 50% longer than metal in environments where rust and corrosion are a nightmare. It’s really changing the game in industries like aerospace, automotive, and electrical, especially since designers love how easily they can mold SMC into all kinds of complex shapes—something that’s pretty tough with regular materials. All in all, SMC is really pushing the boundaries of what's possible in manufacturing these days, blending performance with style in a way that’s pretty hard to ignore.

Innovative Technologies Driving the Use of SMC Sheets

These days, using Sheet Molding Compound (SMC) sheets in industries like automotive, aerospace, and construction is really taking off, thanks to some pretty exciting tech breakthroughs. If you look at the numbers, the global SMC market is expected to jump from about $2.8 billion in 2020 to roughly $4.3 billion in 2025—that's a solid annual growth rate of around 9.1%. Most of this growth seems to come from smarter manufacturing methods and the growing demand for lightweight, tough materials that can stand up to the rigors of modern use.

Lately, we've seen some cool innovations, like better resin mixes and more automation in production lines. These changes have seriously boosted how SMC sheets perform — think stronger, more heat-resistant materials thanks to high-tech fiber composites. This is especially a game-changer for the auto industry, which is now using more SMC for bumpers and body panels. Why? Because it helps lighten vehicles and makes them more fuel-efficient, which folks definitely care about.

Plus, with automation making its way into SMC manufacturing, things are getting faster and more precise. That means less waste and lower costs. I read somewhere that automating these processes can cut down production times by up to 30%—pretty impressive, right? As companies keep pushing forward with new tech, it seems like SMC sheets are going to be even more important in shaping the future of all kinds of industries, especially with sustainability and top-notch performance in mind.

Future Trends in SMC Sheet Applications Across Industries

Looking ahead, the future of SMC (Sheet Molding Compound) sheets in today’s industries definitely seems pretty bright. With lightweight materials becoming all the rage and a big push for sustainable solutions, things are moving quickly. A recent report from MarketsandMarkets suggests that the global SMC market could grow from around 1.4 billion USD in 2022 to about 2 billion USD by 2027. That’s a healthy annual growth rate of roughly 7.5%. Most of this growth is happening in the automotive and aerospace worlds — where SMC sheets are popular because they offer a strong strength-to-weight ratio and can resist various environmental factors.

But it’s not just cars and planes. We're also seeing more use of SMC in renewable energy fields like wind and solar power. For example, the installation of composite parts in wind turbine blades is expected to see a big jump — industry forecasts say nearly a 30% increase by 2025. And, with the rise of electric vehicles, there’s an even bigger push for high-performance SMC sheets that can keep vehicles lightweight without sacrificing durability. As industries keep pushing boundaries and coming up with new innovations, SMC sheets are definitely set to be a key component in the next generation of products across many sectors.

Exploring the Versatility and Applications of PIGC301 Polyimide Glass Cloth Rigid Laminated Sheets in Modern Industries

The PIGC301 Polyimide Glass Cloth Laminated Sheets, developed by Myway, represent a remarkable advancement in material science, tailored for various modern industrial applications. Constructed from a high-quality woven glass cloth that has undergone treatment with KH560, this product optimally combines strength and thermal stability. The unique polyimide thermosetting resin used in the lamination process is vital in ensuring the sheets can withstand extreme temperatures and harsh environments, making them ideal for sectors such as aerospace, electronics, and automotive industries.

One of the standout features of PIGC301 sheets is their versatility. These laminated sheets provide excellent electrical insulation properties and mechanical strength, making them an essential component in manufacturing insulating substrates, printed circuit boards, and protective barriers. Furthermore, the high-temperature resistance of the polyimide resin allows these sheets to maintain performance in applications that require durability under heat, thus enhancing the reliability and longevity of the end products. With this innovative material, industries can achieve heightened efficiency and safety in their operations, showcasing the unmatched potential of PIGC301 Polyimide Glass Cloth Laminated Sheets in contemporary manufacturing.

FAQS

: SMC sheets, or Sheet Molding Compounds, are primarily made from unsaturated polyester resin, fiberglass, and various additives that enhance their mechanical strength and thermal resistance.

SMC sheets are lightweight, durable, corrosion-resistant, and easy to mold into complex shapes, making them a preferred choice over metals and thermoplastics for many applications.

SMC sheets are commonly used in the automotive, electrical, and construction industries, where high performance and longevity of components are required.

The global SMC market is expected to grow from USD 1.4 billion in 2022 to USD 2.0 billion by 2027, with a compound annual growth rate of 7.5%, largely driven by the automotive and aerospace sectors.

SMC sheets are emerging in the renewable energy sector, particularly in wind and solar energy, with a projected increase in their use for composite components in wind turbine blades by nearly 30% by 2025.

The trend towards electric vehicles (EVs) is expected to boost the demand for high-performance SMC sheets which provide durability while maintaining the lightness essential for EVs.

The superior strength-to-weight ratio of SMC sheets makes them ideal for applications in automotive and aerospace sectors, where reducing weight while maintaining strength is critical.

Yes, one of the key advantages of SMC sheets is their ease of molding into complex shapes, allowing for intricate designs while maintaining structural integrity.

The expansion is driven by the increasing demand for lightweight materials and sustainable solutions, along with innovations in various sectors, including automotive and renewable energy.

Conclusion

You know, SMC sheets—also called Sheet Molding Compounds—are these composite materials that have really proven their worth, especially when it comes to solid mechanical strength and versatility. No wonder they’re becoming pretty popular in all sorts of industries. In this guide, I’ll break down what makes SMC sheets so special, especially their awesome weight-to-strength ratio—way better than the usual materials you might be used to. Companies like Sichuan D&F Electric Co., Ltd. are actually leveraging these sheets for electrical connection parts and insulation components, which really shows how effective they are in making products more durable and performing better overall.

As innovation kicks into gear, more industries are starting to push the boundaries—testing out new tech and applications for SMC sheets that could totally shake up how things are made. Looking ahead, with a strong focus on sustainability and efficiency, the future for SMC sheets looks pretty bright. This guide will walk you through the latest trends and how these sheets are transforming various sectors, proving they're destined to be a key material in today’s modern manufacturing world.

Related Posts

-

The Future of China Epoxy Glass Fiber Sheet in Global Markets

-

Ultimate Guide to Choosing the Right Flexible Busbar Connectors for Your Systems

-

The Future of Innovation in the Copper Aluminum Busbar Market

-

Exploring Unique Custom Molding Part Alternatives for Global Buyers

-

How to Choose the Right Flexible Copper Strip for Optimal Electrical Performance

-

Understanding the Importance of Dc-Link Busbar in Modern Power Systems