The Ultimate Guide to Understanding Glass Polyester Laminate for Your Projects

Table of Contents

- Understanding the Composition and Strength of Glass Polyester Laminate Materials

- Key Applications of Glass Polyester Laminate in Various Industries

- Analyzing the Durability and Longevity of Glass Polyester Laminates

- Comparative Cost-Effectiveness of Glass Polyester Laminate vs Other Materials

- Sustainability Considerations for Glass Polyester Laminate in Project Planning

- Best Practices for Working with Glass Polyester Laminate in Construction

- Transforming Composite Applications: Insights from Industry Reports on GPO-3 (UPGM203) Unsaturated Polyester Glass Mat Laminated Sheets

- FAQS

- Conclusion

- Related Posts

Lately, there's been a real uptick in demand for advanced materials across different industries. One standout lately is Glass Polyester Laminate, which is gaining popularity not just for electrical uses but also for structural ones. If you look at market trends, the global market for fiberglass-reinforced plastics—including this very material—is expected to jump from around $14.5 billion in 2021 to roughly $27.8 billion by 2026. That's a solid growth rate of about 13.8% annually. So, it’s no surprise—people are really craving lightweight yet tough materials that insulate well and can handle mechanical stress. Sichuan D&F Electric Co., Ltd., which has been around since 2005, definitely gets this vibe. They're all about providing top-notch electrical connection components and insulating parts, tailored to meet the changing needs of industries relying on Glass Polyester Laminate. Getting a good grasp of this material’s properties and benefits is pretty crucial if you're looking to upgrade your projects with the latest and greatest solutions.

Understanding the Composition and Strength of Glass Polyester Laminate Materials

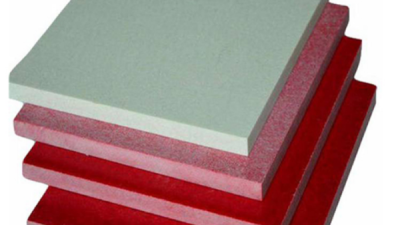

Glass polyester laminate is basically a mix of glass fibers and polyester resin, making it a pretty tough and lightweight material. Think of it like layers of glass fabric that give it strength, while the resin holds everything together and boosts its durability—plus, it resists moisture quite well. This combo not only makes the material stronger in tension but also tough enough to handle different environmental conditions. That’s why you see it used all over, from building sites to boats out in the water.

Getting a good handle on how strong glass polyester laminate is can really help you pick the right material for your project. It’s got some pretty impressive mechanical qualities, like high flexibility without breaking and low shrinkage, which are super important when things get stressful or under pressure. Plus, it’s resistant to chemicals and UV rays, so it’s a no-brainer for outdoor use. Knowing these little details helps planners and designers make smarter choices, ensuring the materials they choose will not only look good and perform well but also last a long time without surprises.

Key Applications of Glass Polyester Laminate in Various Industries

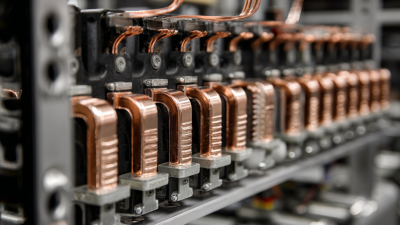

Glass polyester laminate is pretty well-known for its durability and versatility. You’ll find it being used across a bunch of different industries that need materials they can count on to be tough and reliable. Basically, this composite stuff—made from glass fibers and polyester resin—provides fantastic electrical insulation, which makes it perfect for electrical and electronic parts. Whether you're talking about cars, planes, or renewable energy setups, glass polyester laminate is favored because it’s lightweight and stands up well to environmental challenges, ensuring it keeps working in tough conditions.

At Sichuan D&F Electric Co., Ltd., we really take pride in using glass polyester laminate in our products, especially when it comes to electrical connectors and insulation parts. We’ve been around since 2005, based in the Jinshan Industrial Park in Deyang, and we’re all about delivering quality solutions that meet our clients’ needs. Our know-how with advanced materials like this laminate helps us make products that are not just reliable but also safe and durable across different applications. That’s why, over the years, we’ve built a solid reputation as a trusted name in the electrical industry.

Analyzing the Durability and Longevity of Glass Polyester Laminates

If you're working on a project that needs to be tough and last a long time—especially in challenging environments like near the water—glass polyester laminate is a pretty solid choice. These materials are great when your components face the constant battering of wind, waves, and tides. They really hold up well, showing excellent resilience under such tough conditions. In fact, studies suggest that these laminates have pretty high impact strength—way better than natural fiber options—so they stand the test of time even when things get rough out there.

When you're picking out materials for your project, here are a couple of tips: First off, aim for a glass content between 25-35%. That range tends to give you the best mechanical performance. Also, it’s a smart idea to do some thorough fatigue testing—basically, see how the material holds up over lots of use—to avoid surprises and prevent early failures. Taking these steps can really boost the durability and reliability of your marine structures.

And don’t forget about thermal stuff, like the glass transition temperature (Tg) and melting point. Knowing these details helps you figure out how the material will perform under different temperature conditions. Using high-quality glass polyester laminates isn’t just about making your stuff last longer; it’s also about ensuring that your setup can handle whatever nature throws at it over time.

Comparative Cost-Effectiveness of Glass Polyester Laminate vs Other Materials

When choosing materials for construction or manufacturing projects, cost is often a big deal for professionals—and rightfully so. Lately, glass polyester laminate has been catching more attention as a pretty solid option. It comes with quite a few advantages that you might find similar to traditional materials like wood, metal, or fiberglass. One of the biggest perks? Its awesome strength-to-weight ratio. This means it’s lighter but still strong, which can help cut down on shipping and handling costs—and let’s be honest, that’s a big plus for the bottom line.

On top of that, durability really works in its favor. Unlike wood, which can rot or fall victim to pests, or metal, which might rust and require constant upkeep, glass polyester laminate holds up pretty well against the elements. That kind of resilience means you won’t need to replace it as often, saving money in the long run. Plus, it’s super versatile—can be shaped and adapted for different uses, which means less waste and more efficient projects. When you compare these perks to the ongoing costs of other materials, it’s pretty clear that glass polyester laminate is a smart, cost-effective choice for modern-building projects.

Sustainability Considerations for Glass Polyester Laminate in Project Planning

When you're thinking about projects that involve glass polyester laminate, it's really important to keep sustainability in mind. This material isn’t just durable and good-looking; it also opens up some pretty cool opportunities to go green. For example, sourcing laminate from manufacturers who focus on eco-friendly production methods can make a big difference in cutting down your project's environmental footprint. And don’t forget about using recycled materials for your laminate—saving waste and conserving resources is always a win.

Here's a handy tip: always ask about the lifecycle of the glass polyester laminate you're eyeing. Knowing how it’s made, how much energy goes into producing it, and whether it can be recycled once you’re done with it can really help you pick the most sustainable option.

Also, think about how your project will be used. See if there's a chance to combine your laminate with other eco-friendly materials—sometimes mixing things up can boost the environmental benefits. And, opting for a modular design can make things easier when it's time to disassemble or recycle components, which is a great step toward a circular approach.

Another tip—work closely with architects and designers who are seasoned in sustainable building practices. They can help you integrate glass polyester laminate smoothly into your project while meeting green building standards. It’s all about making smart choices that are good for the planet, but still look great and function well.

Best Practices for Working with Glass Polyester Laminate in Construction

Whenever you’re working with glass polyester laminate in construction, it’s super important to follow some best practices to make sure everything holds up well and looks great in the long run. First off, don’t skip on proper surface prep — cleaning and sanding the surface is a must so the laminate can really stick. Throwing on a primer can help it stick even better and also boost its lifespan, plus it stops moisture from sneaking in and messing things up later on. Oh, and keep an eye on the weather while you're working — humidity and temperature can really throw off the curing process and affect how the finish turns out.

On top of that, using the right fabrication techniques makes all the difference. For example, cutting the laminate carefully with the right tools prevents chipping and gives you those nice, clean edges. When you’re joining pieces together, make sure to choose the right adhesives — it’s all about keeping everything sturdy and reliable. Also, think about the load your project needs to handle; glass polyester laminate is a pretty solid choice because it’s lightweight but strong as heck. And don’t forget, doing regular maintenance checks will help keep your laminate looking good and lasting longer. If you catch issues early, repairs or replacements are much easier. Stick to these tips, and your project will not only perform better but will look fantastic too!

Transforming Composite Applications: Insights from Industry Reports on GPO-3 (UPGM203) Unsaturated Polyester Glass Mat Laminated Sheets

In the evolution of composite applications, the UPGM203 unsaturated polyester glass mat laminated sheets stand out, particularly the notable GPO-3 Molded Sheet. This advanced material is not only recognized for its superior machinability but also boasts impressive mechanical strength, making it a preferred choice among industries requiring reliable and durable components. The unique composition of alkali-free glass mat combined with unsaturated polyester resin, molded under high temperature and high pressure, results in a product that is both robust and efficient.

The dielectric properties of GPO-3 render it exceptionally suitable for electrical insulation applications. Furthermore, its excellent proof tracking resistance and arc resistance make it an ideal candidate for use in demanding environments where safety and reliability are paramount. Being UL certified and compliant with REACH and RoHS regulations, GPO-3 ensures peace of mind for manufacturers and end-users alike, emphasizing the combination of performance and environmental responsibility.

As industries continue to transform and innovate, materials like GPO-3 will play a pivotal role in shaping future applications. The insights drawn from industry reports reveal a growing trend towards utilizing high-performance composites that not only meet but exceed traditional standards. Embracing materials like GPO-3 can significantly enhance product development, offering a blend of strength, safety, and sustainability crucial for modern manufacturing.

FAQS

: Glass polyester laminate is composed of glass fibers and polyester resin, which combine to create a lightweight and robust material.

Key benefits include high tensile strength, moisture resistance, chemical resistance, UV protection, and impressive mechanical properties like high flexural strength and low shrinkage.

It showcases excellent durability and impact strength, allowing it to withstand the stresses of wind, waves, and tides, making it ideal for marine applications.

Ensure the glass content is between 25-35%, conduct a fatigue life analysis to predict performance, and assess thermal properties like glass transition temperature.

Focus on sourcing from manufacturers with sustainable practices, consider using recycled materials, and inquire about the material's lifecycle and potential for recycling.

Investigate combining the laminate with other sustainable materials, adhere to modular design principles for easier disassembly, and collaborate with knowledgeable architects and designers.

Conclusion

Hey there! If you're curious about Glass Polyester Laminate and how it can fit into your projects, our guide — 'The Ultimate Guide to Understanding Glass Polyester Laminate for Your Projects' — is a great starting point. We dive into what this material is made of and why it’s so tough and reliable. You’ll see how it’s used in all sorts of industries, from insulating electrical parts to structural stuff. Plus, we talk about how it stacks up cost-wise against other materials, which makes it pretty appealing for folks planning their projects.

On top of that, we touch on how companies are leaning more towards eco-friendly practices, and how Glass Polyester Laminate is evolving with sustainability in mind. Lastly, we share some handy tips for working with it in construction, so you can get the most out of this material while sticking to industry standards. For companies like Sichuan D&F Electric Co., Ltd., understanding these basics can really make a difference in delivering solid electrical parts and insulation solutions that customers can trust.

Related Posts

-

Solutions for Enhancing Electrical Efficiency with Silver Plated Copper Bus Bars

-

Global Market Insights: Projecting the Future of Best Epoxy Fiberglass Tubes by 2025

-

Essential Checklist for Global Buyers: Navigating Gpo3 Machining Procurement

-

The Ultimate Checklist to Choosing the Best Copper Bus Bar for Global Procurement

-

Exploring the Unique Properties and Applications of Best Nomex T410 Film: A Comprehensive Guide for Buyers

-

Unlocking the Advantages of Bare Copper Strip in Electrical Applications for Energy Efficiency