Exploring Unique Custom Molding Part Alternatives for Global Buyers

Table of Contents

- Exploring the Trends in Custom Molding Solutions for Global Industries

- Key Statistics on the Growth of the Custom Molding Market in 2023

- Innovative Materials Shaping the Future of Custom Molding Parts

- Cost-Effective Custom Molding Alternatives for International Buyers

- The Role of Sustainability in Custom Molding Part Production

- Technological Advancements Revolutionizing Custom Molding Techniques

- Enhancing Energy Efficiency: Insights from Industry Reports on Custom Molded Insulation Structural Parts Performance and Impact

- FAQS

- Conclusion

- Related Posts

You know, in the always-changing world of manufacturing, there's never been a bigger demand for custom solutions. I recently came across a report by MarketsandMarkets that said the global market for custom molding is expected to hit over $18 billion by 2025. That really shows how much companies are looking for personalized parts to fit their specific needs across different industries. As businesses worldwide search for unique molding options to streamline their operations, Sichuan D&F Electric Co., Ltd. definitely stands out as a trusted partner. Founded back in 2005 and based in the Jinshan Industrial Park in Deyang, Sichuan, they focus on high-quality electrical connection components and insulation parts. In this guide, we'll take a look at some innovative alternatives to traditional custom molding parts—solutions that can boost productivity and efficiency while also meeting the specific needs of clients all around the globe.

Exploring the Trends in Custom Molding Solutions for Global Industries

The world of custom molding solutions is changing really fast these days, mostly thanks to new tech and shifting industry demands. More and more sectors are looking for innovative ways to boost production efficiency and improve product quality, which is why options like custom molding are really catching on. The plastic injection molding market, for example, is expected to hit about $235.7 billion by 2024—that’s a clear sign that companies are relying more than ever on customized manufacturing solutions. This all points to how important it is for manufacturers to stay adaptable and keep up with tech advancements to meet the wide range of needs out there.

Lately, industries are especially into custom molding methods that can handle complex designs and mix different materials—think thermoset injection molding. Not only does this process help create detailed, intricate parts, but it also makes it easier to add embedded features that modern products often require. As buyers worldwide look into these unique molding options, the focus on precision and dependability is only going to grow. That’s pushing manufacturers to invest in the latest tech innovations that match current market trends.

All in all, the rising demand for these specialized solutions reflects a bigger shift toward more sustainable and efficient manufacturing practices, which is opening up exciting possibilities across a bunch of industries.

Key Statistics on the Growth of the Custom Molding Market in 2023

Hey, did you know that the custom molding market is really booming in 2023? It’s kind of part of a bigger trend we’re seeing across a bunch of different industries. Recent numbers show that the global plastic injection molding market alone hit around $191 billion, and it's only expected to keep growing. That just shows how much demand there is for tailored, made-to-order solutions in manufacturing right now. A big part of this growth comes from tech advancements and a supply chain that's become more responsive to what various sectors—like automotive and electronics—actually need.

Now, when companies are on the hunt for reliable partners to make electrical connection parts or insulation pieces, Sichuan D&F Electric Co., Ltd. really stands out in this field. They've been around since 2005 and really focus on quality and customization. They’re all about crafting solutions that fit the ever-changing demands of buyers worldwide. With the custom molding market heading for some serious expansion, companies like D&F are pretty essential—they’re helping deliver products that boost performance and efficiency while keeping up with market trends.

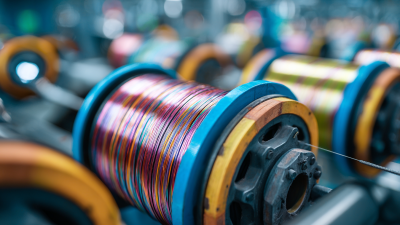

Innovative Materials Shaping the Future of Custom Molding Parts

You know, innovative materials are really shaking up the custom molding parts industry right now. They're giving buyers all around the world some pretty cool options that boost both functionality and sustainability. Stuff like advanced polymers, bio-based materials, and composites—these are just a few ways innovation is changing the game. Take thermoplastic elastomers, for example. Using them doesn’t just mean parts that are flexible and durable; they’re actually easier to recycle compared to the traditional options, which is a big plus. This move toward greener practices is becoming more and more important, especially as industries look to cut down their environmental impact while still hitting high-performance benchmarks.

And then there's the rise of 3D printing, which is totally changing the way we make molds. Now we can create really complex, customized designs that used to be impossible or way too costly. It’s a real game-changer—making the whole process faster, cutting down lead times, and saving some bucks for clients. By tapping into these new materials and tech, manufacturers can whip up lighter, stronger, and more efficient products that match what each customer specifically needs. As everyone’s pushing for more efficiency and sustainability, diving into these fresh options is pretty much essential if manufacturers want to stay ahead in the rapidly changing world of custom molding parts.

Exploring Unique Custom Molding Part Alternatives for Global Buyers - Innovative Materials Shaping the Future of Custom Molding Parts

| Material Type | Properties | Applications | Cost Efficiency | Sustainability |

|---|---|---|---|---|

| Biodegradable Polymers | Eco-friendly, compostable, moderate strength | Packaging, disposable cutlery | Moderate | High |

| Glass Filled Plastics | High strength, improved thermal stability | Automotive parts, industrial applications | High | Moderate |

| Thermoplastic Elastomers (TPE) | Flexible, durable, weather-resistant | Consumer goods, seals, gaskets | Moderate | Moderate |

| Carbon Fiber Composites | Lightweight, high tensile strength, stiffness | Aerospace, sports equipment | Low | Low |

| Silicone Rubber | High flexibility, temperature resistant, non-toxic | Medical devices, kitchenware | Moderate | High |

Cost-Effective Custom Molding Alternatives for International Buyers

In today’s global market, international buyers are always on the lookout for more affordable options when it comes to custom molding parts. Thanks to tech advancements—especially in 3D printing and manufacturing—companies now have a ton of choices at their fingertips. Online 3D printing services, for example, have really changed the game, letting manufacturers produce custom parts on demand. That means shorter lead times, less money tied up in inventory, and the ability to meet specific design needs more easily. It’s a win all around — not only does this boost operational efficiency, but it also opens doors for businesses to get creative with their products without breaking the bank.

Plus, there’s a big trend nowadays toward built-to-order models. This makes it easier for companies to respond quickly to what the market actually wants, while also cutting down on waste and avoiding piling up excess stock. And don’t forget, there are now more affordable services popping up that still deliver high-quality results. This means global buyers don’t have to settle for less or compromise on quality. As things keep evolving in the world of custom molding, taking advantage of these newer options helps businesses stay competitive and find smarter ways to produce what they need.

The Role of Sustainability in Custom Molding Part Production

These days, sustainability is a huge deal in the manufacturing world, especially when it comes to making custom molding parts. Companies are really leaning into new, greener practices—that's become pretty much essential if they want to keep up with the growing demand for eco-friendly solutions.

More and more folks are working on cutting down waste and boosting efficiency; for example, some businesses are now sending less than 1% of their waste to landfills, and they're also making big cuts in water use. This shift isn’t just about hitting global sustainability targets—it’s also a smart move to attract buyers who care deeply about the environment.

Lately, using alternative materials like recycled plastics in these processes is getting more popular. Some manufacturers are even mixing recycled with virgin plastics, which shows how creative the industry is becoming.

On top of that, the rise of reusable molds—like, molds you can use endlessly—opens up a whole new world of possibilities for cutting down waste and speeding up production. As companies look for smarter, more efficient ways to get things done, it’s clear that sustainable approaches will keep playing a bigger role in custom molding.

At the end of the day, it’s all about doing things better for the planet without sacrificing innovation.

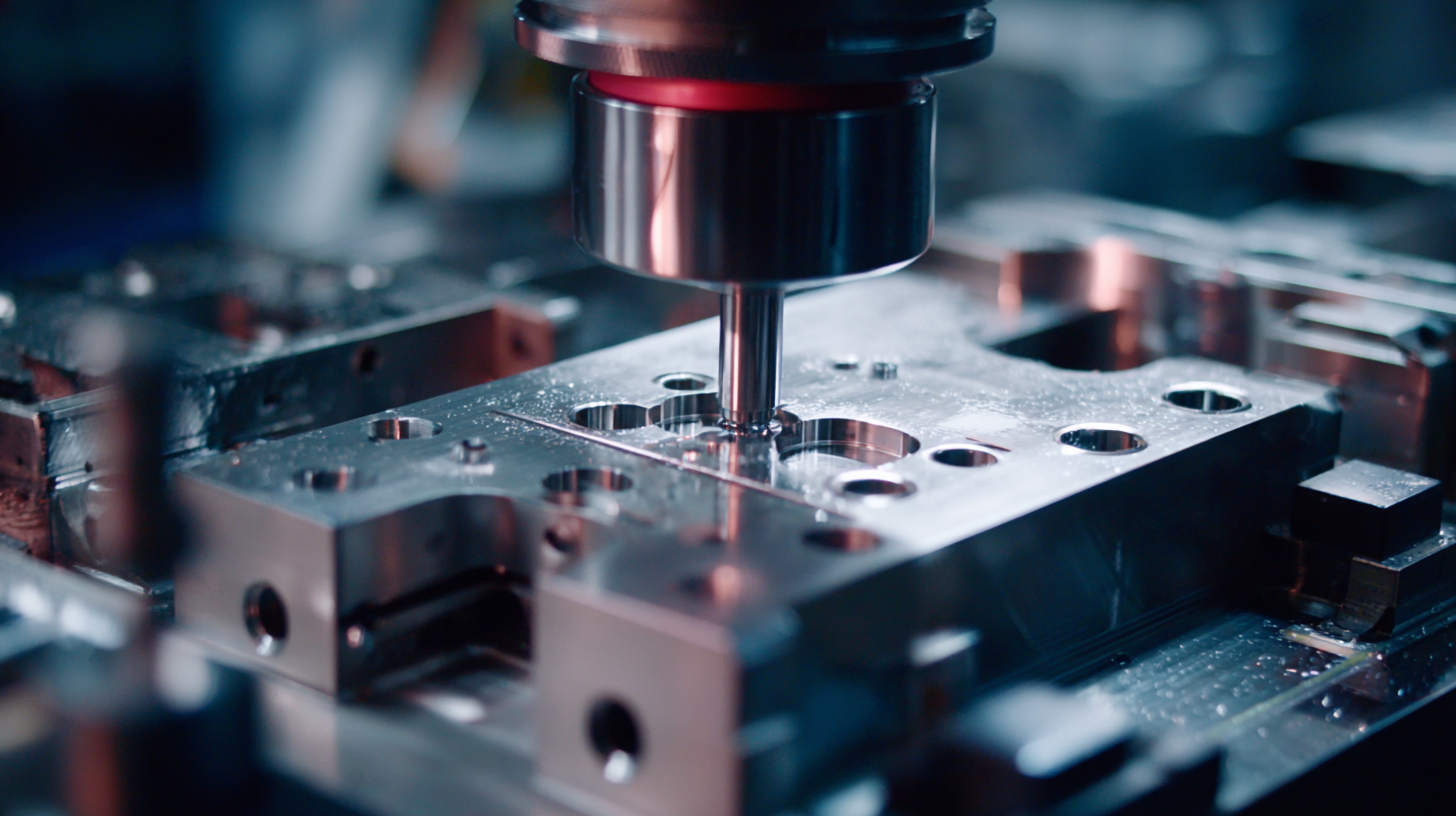

Technological Advancements Revolutionizing Custom Molding Techniques

Hey, have you noticed how the world of custom molding is really going through a major transformation lately? Thanks to all these crazy-fast tech advancements, things are changing pretty quickly. Techniques like 3D printing, automated molding, and CNC machines are making it possible for manufacturers to craft really intricate designs with a level of precision that, honestly, feels like science fiction. Not only does this mean they can produce parts faster and more efficiently, but it also cuts down the wait time quite a bit. So, global buyers can get their hands on custom solutions way quicker than before — it’s pretty exciting stuff.

If you're on the hunt for unique alternative parts in custom molding, there are some tips I’d definitely recommend. First off, get super clear about what you need — think about materials, sizes, and just how complex your design should be. Knowing all that upfront really helps when you're chatting with manufacturers, making sure everyone’s on the same page. Also, don’t overlook the power of modern software for prototyping. These tools let you quickly test out ideas, make tweaks, and perfect your design before going into full-blown production. It saves both time and money in the long run.

And here’s a bonus tip for those of us shopping from around the world — stay in the loop about the latest and greatest in custom molding tech. Sign up for industry newsletters, hit up trade shows when you can, and keep an eye out for new materials or methods. Keeping yourself informed can really give you an edge — maybe even help you spot some cool innovations that could make your products stand out in the market.

Exploring Unique Custom Molding Part Alternatives for Global Buyers

Enhancing Energy Efficiency: Insights from Industry Reports on Custom Molded Insulation Structural Parts Performance and Impact

In the pursuit of enhancing energy efficiency within various industries, custom molded insulation structural parts play a pivotal role. By leveraging advanced thermal pressing molding technology, manufacturers can create complex insulation components that not only improve production efficiency but also significantly reduce costs. This innovative approach allows for the fabrication of high-performance parts tailored to meet specific needs, paving the way for better energy management in a broad range of applications.

Custom molded products, particularly those made from Sheet Molding Compound (SMC) or Dough Molding Compound (DMC), exhibit remarkable characteristics that contribute to their effectiveness. Under high temperature and pressure conditions, these materials achieve superior mechanical and dielectric strength, along with exceptional flame resistance. Moreover, they demonstrate low water absorption and stable dimensional tolerance, making them ideal for environments that require reliability and durability. The significant benefits—including increased arc resistance and high withstand voltage—make these custom insulation parts crucial to enhancing overall energy efficiency while maintaining safety and performance standards in various sectors.

FAQS

: Innovative materials include advanced polymers, bio-based materials, thermoplastic elastomers, and composites, which enhance functionality and sustainability.

Thermoplastic elastomers not only create flexible and durable parts but also offer better recycling opportunities compared to traditional materials.

3D printing enables the creation of highly customized molds with intricate designs, streamlining production processes and significantly reducing lead times and costs.

Sustainability is crucial as it helps reduce environmental impact, aligns with global sustainability goals, and meets the rising demand for environmentally friendly solutions.

Companies are reducing waste by implementing practices that lead to less than 1% of waste sent to landfills and significantly diminishing water usage.

Recycled plastics are becoming increasingly popular, with techniques that combine virgin and recycled materials being used to enhance sustainability.

Infinitely reusable molds help reduce material waste while simultaneously enhancing production speeds.

As the demand for efficiency and sustainability increases, exploring innovative materials and techniques becomes essential for manufacturers to remain competitive.

Advanced materials allow for the production of lighter, stronger, and more efficient products that can be tailored to specific customer needs.

Businesses are prioritizing ecological responsibility by integrating sustainable practices and exploring alternative materials to create a more environmentally friendly production process.

Conclusion

You know, with how quickly everything's changing in the world of manufacturing, custom molding parts are really stepping into the spotlight for a lot of industries that need personalized components. I thought I’d share some of the latest trends—2023 was a big year, with some impressive growth stats that clearly show how demand is skyrocketing. What’s interesting is how new, innovative materials are pushing things forward—they’re not just making the parts better in performance but are also more eco-friendly, which is pretty cool.

For international buyers, finding cost-effective options is often a must, especially since competition is tough out there. Companies like Sichuan D&F Electric Co., Ltd., are doing some pretty exciting work—they’re reliable sources for electrical connections and insulation parts. Oh, and tech improvements are really changing the game too—making manufacturing faster, more efficient, and greener. As this industry keeps evolving, I think the spotlight on sustainability will just keep growing, making it an important thing for buyers around the world to keep an eye on.

Related Posts

-

5 Key Insights on Winding Insulation Class for Optimal Motor Performance

-

Global Market Insights: Projecting the Future of Best Epoxy Fiberglass Tubes by 2025

-

The Ultimate Checklist to Choosing the Best Copper Bus Bar for Global Procurement

-

The Ultimate Guide to Laminated Bus Bars for the EV Market: Optimizing Performance and Efficiency

-

How to Choose the Best Tin Plated Copper Bus Bar for Your Electrical Needs

-

Exploring Alternative Options to Best Gpo3 Sheets for Savvy Global Buyers