OEM Manufacturer Epoxy Glass Cloth Laminated Sheets H Class G11 - 3240 Epoxy Phenolic Glass Cloth Base Rigid Laminated Sheet – D&F

OEM Manufacturer Epoxy Glass Cloth Laminated Sheets H Class G11 - 3240 Epoxy Phenolic Glass Cloth Base Rigid Laminated Sheet – D&F Detail:

Technical Requirements

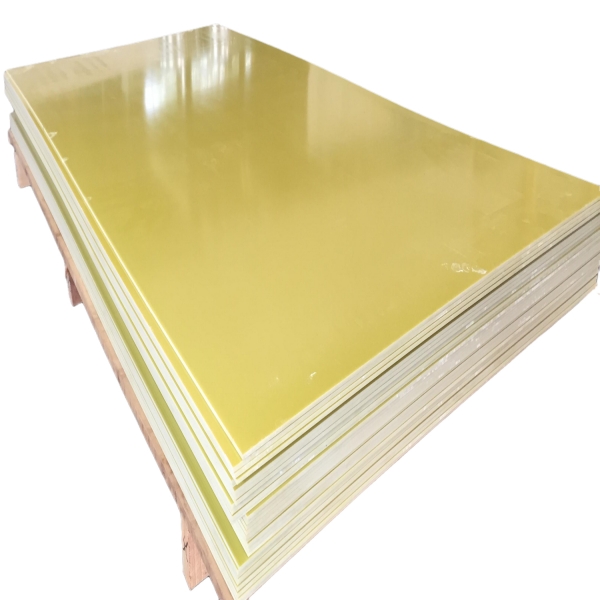

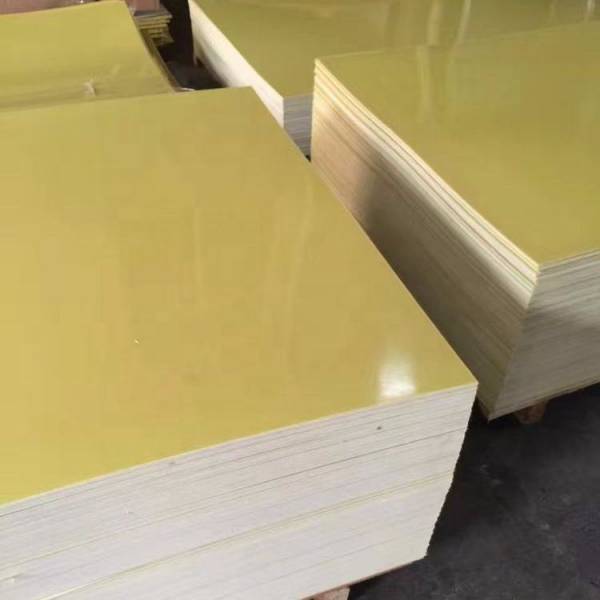

1.1 Appearance: the surface of sheet shall be flat and smooth, free of air bubbles, wrinkles or cracks and reasonably free of other small imperfections such as scratches, dents, etc. The edge of sheet shall be tidy and be free of delaminations and cracks. The color shall be substantially uniform, but a few stains are permissible.

1.2 Dimension and allowed tolerance

1.2.1 Width and Length of Sheets

|

Width & Length (mm) |

Tolerance (mm) |

|

>970~3000 |

+/-25 |

1.2.2 The nominal thickness & tolerance

|

Nominal thickness (mm) |

Tolerance (mm) |

Nominal thickness (mm) |

Tolerance (mm) |

|

0.5 0.6 0.8 1.0 1.2 1.6 2.0 2.5 3.0 4.0 5.0 6.0 8.0 |

+/-0.12 +/-0.13 +/-0.16 +/-0.18 +/-0.20 +/-0.24 +/-0.28 +/-0.33 +/-0.37 +/-0.45 +/-0.52 +/-0.60 +/-0.72 |

10 12 14 16 20 25 30 35 40 45 50 60 80 |

+/-0.82 +/-0.94 +/-1.02 +/-1.12 +/-1.30 +/-1.50 +/-1.70 +/-1.95 +/-2.10 +/-2.30 +/-2.45 +/-2.50 +/-2.80 |

| Remarks: For the non-nominal thickness not listed in this table, the deviation shall be the same as that of the next greater thickness. | |||

1.3 Bending Deflection

|

Thickness (mm) |

Bending Deflection |

|

| 1000mm(Ruler length) (mm) |

500mm(Ruler length)(mm) |

|

|

3.0~6.0 >6.0~8.0 >8.0 |

≤10 ≤8 ≤6 |

≤2.5 ≤2.0 ≤1.5 |

1.4 Mechanical processing: the sheets shall be free of cracks, delaminations and scraps when such machining as sawing, drilling, lathing and milling is applied

1.5 The physical, mechanical and electrcal properties

|

No. |

Properties |

Unit |

Standard value |

Typical value |

|

1 |

Density |

g/cm3 |

1.7~1.95 |

1.94 |

|

2 |

Water absoprtion (2mm sheet) |

mg |

≤20 |

5.7 |

|

3 |

Flexural strength, perpendicular to laminations |

MPa |

≥340 |

417 |

|

4 |

Impact strength (Charpy, notch) |

kJ/m2 |

≥30 |

50 |

|

5 |

Dielectric dissipation factor 50Hz |

— |

≤5.5 |

4.48 |

|

6 |

Dielectric constant 50Hz |

— |

≤0.04 |

0.02 |

|

7 |

Insulation resistance ( After 24h in water) |

Ω |

≥5.0 x108 |

4.9 x109 |

|

8 |

Dielectric strength, perpendicular to laminationsin transformer oil at 90℃+/-2℃, 1mm sheet |

kV/mm |

≥14.2 |

16.8 |

|

9 |

Breakdown Voltage, parallel to laminationsin transformer oil at 90℃+/-2℃ |

kV |

≥35 |

38 |

Packing, Transportation and Storage

The sheets shall be stored in a place where temperature is no higher than 40℃, and be placed horizontally on a bedplate with a height of 50mm or above. Keep away from fire, heat (heating apparatus) and direct sunshine. The storage life of sheets is 18 months from the date of leaving factory. If the storage duration is over 18 months, the product also could be used after being tested to be qualified.

Remarks and Precautions for Application

A high speed and small cutting depth g shall be applied when machining because of sheets’ weak thermal conductivity.

Machining and cutting this product will release much dust and smoke. Suitable measures should be taken to ensure dust levels are within acceptable limits during operations. Local exhaust ventilation and using the dust/particle masks are advised.

The sheets are subject to moisture after being machined, a coating of insulating vanish is recommended.

Production Equipment

The Package For Laminated Sheets

Product detail pictures:

Related Product Guide:

We are convinced that with joint endeavours, the small business between us will bring us mutual benefits. We could assure you products quality and competitive selling price for OEM Manufacturer Epoxy Glass Cloth Laminated Sheets H Class G11 - 3240 Epoxy Phenolic Glass Cloth Base Rigid Laminated Sheet – D&F , The product will supply to all over the world, such as: Guatemala, Korea, Armenia, If any item be of interest to you, please let us know. We will try our best to satisfy your requirements with high quality products, the best prices and prompt delivery. Please feel free to contact us at any time. We will reply you when we receive your inquiries. Please note that samples are available before we start our business.

The sales manager has a good English level and skilled professional knowledge, we have a good communication. He is a warm and cheerful man, we have a pleasant cooperation and we became very good friends in private.