Top Suppliers Cooling Techniques - Custom rigid copper or aluminum bus bar – D&F

Top Suppliers Cooling Techniques - Custom rigid copper or aluminum bus bar – D&F Detail:

D&F has over 17 years of CNC machining experience. D&F can produce and supply all kinds of high-quality copper bus bars as per users’ drawings or technical requirements.

Rigid copper bus bar, It is CNC machined from copper sheets or copper bars. For the the long rectangles conductors with has cross section of rectangular or chamfering (rounded), generally the user will use the rounded copper bars to avoid point discharge. It plays the role of conveying current and connecting electrical equipment in the circuit.

Our rigid copper bus bar bar is processed in our automatic bus bar production line. According to customer’s technical drawings, we can produce a variety of high conductivity connection copper bar with various specifications & complex shape.

Our rigid copper bars are processed from T2Y2 copper material (C11000), the copper content is over more than 99.9%. All raw materials and finished parts have a 100% full inspection before production, quality can be assured.

According user’s requirement, the copper bar can be tin plated, nickel plated or silver plated or coated with heat shrink insulating tubes with different voltage requirement.

Products Features

Rigid copper /aluminum bus bars have the advantages of low resistivity, high current-carrying capacity, high conductivity and larger bending degree.

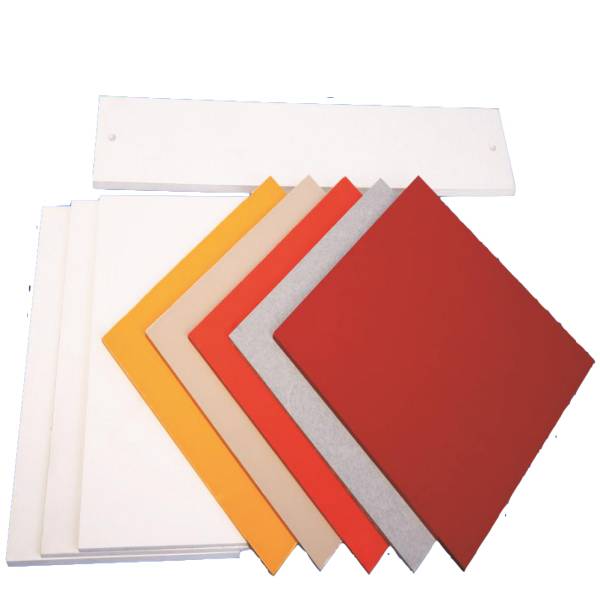

Surface Treatment

Tin, nickel, silver, gold plating. Coating epoxy insulation layer and heat shrink tubes.

Applications

Rigid copper bar is a kind of high current conductive product, which is suitable for high and low voltage electrical equipment, especially in complete sets of distribution devices, switch contacts, electric power distribution equipment, bus bar duct and other electrical engineering, but also widely used in metal smelting, electrochemical electroplating, chemical caustic soda and other super current electrolytic smelting engineering.

Production Equipment For Rigid Copper or Aluminum Bus Bar.

Product detail pictures:

Related Product Guide:

We stay with the basic principle of "quality initially, services first, steady improvement and innovation to fulfill the customers" for your management and "zero defect, zero complaints" as the quality objective. To perfect our company, we give the goods while using the good high-quality at the reasonable selling price for Top Suppliers Cooling Techniques - Custom rigid copper or aluminum bus bar – D&F , The product will supply to all over the world, such as: Liberia, Azerbaijan, Czech republic, So that you can utilize the resource from the expanding info in international trade, we welcome shoppers from everywhere on-line and offline. In spite of the good quality solutions we provide, effective and satisfying consultation service is supplied by our professional after-sale service team. Product lists and detailed parameters and any other info weil be sent to you timely for your inquiries. So you should make contact with us by sending us emails or call us if you have any questions about our corporation. ou may also get our address info from our web page and come to our company to get a field survey of our merchandise. We've been confident that we have been going to share mutual achievement and create strong co-operation relations with our companions in this marketplace. We're searching forward for your inquiries.

We have been appreciated the Chinese manufacturing, this time also did not let us disappoint,good job!