How to Choose the Right Flexible Busbar Solutions for Your Industrial Needs

Table of Contents

- Understanding Flexible Busbar: Definition and Applications

- Key Factors in Selecting Flexible Busbar Solutions

- Comparing Materials: Copper vs. Aluminum Busbars

- Evaluating Electrical Specifications for Your Needs

- Installation and Maintenance Considerations for Busbar Systems

- Case Studies: Successful Implementations of Flexible Busbars in Industry

- Exploring the Benefits of 6641 F-class DMD Flexible Composite Insulation Paper in Electrical Applications

- FAQS

- Conclusion

- Related Posts

In today’s fast-changing industrial world, picking the right flexible busbar solutions has really become a big deal for making sure electrical connections are reliable and well-insulated. The flexible busbar market is growing pretty quickly, mainly because more industries are really pushing for dependable power distribution systems. But here's where it gets tricky — finding the perfect busbar setup that fits your specific needs isn’t always straightforward. That's where companies like Sichuan D&F Electric Co., Ltd. come in. They've been around since 2005, specializing in top-notch electrical connection parts and insulation components, and they’re really leading the charge in this space. In this blog, I’ll walk you through some key points to consider when choosing the best flexible busbar options for your industrial projects. Plus, I’ll stress how important it is to team up with trustworthy suppliers like D&F to make sure your electrical infrastructure is solid and reliable.

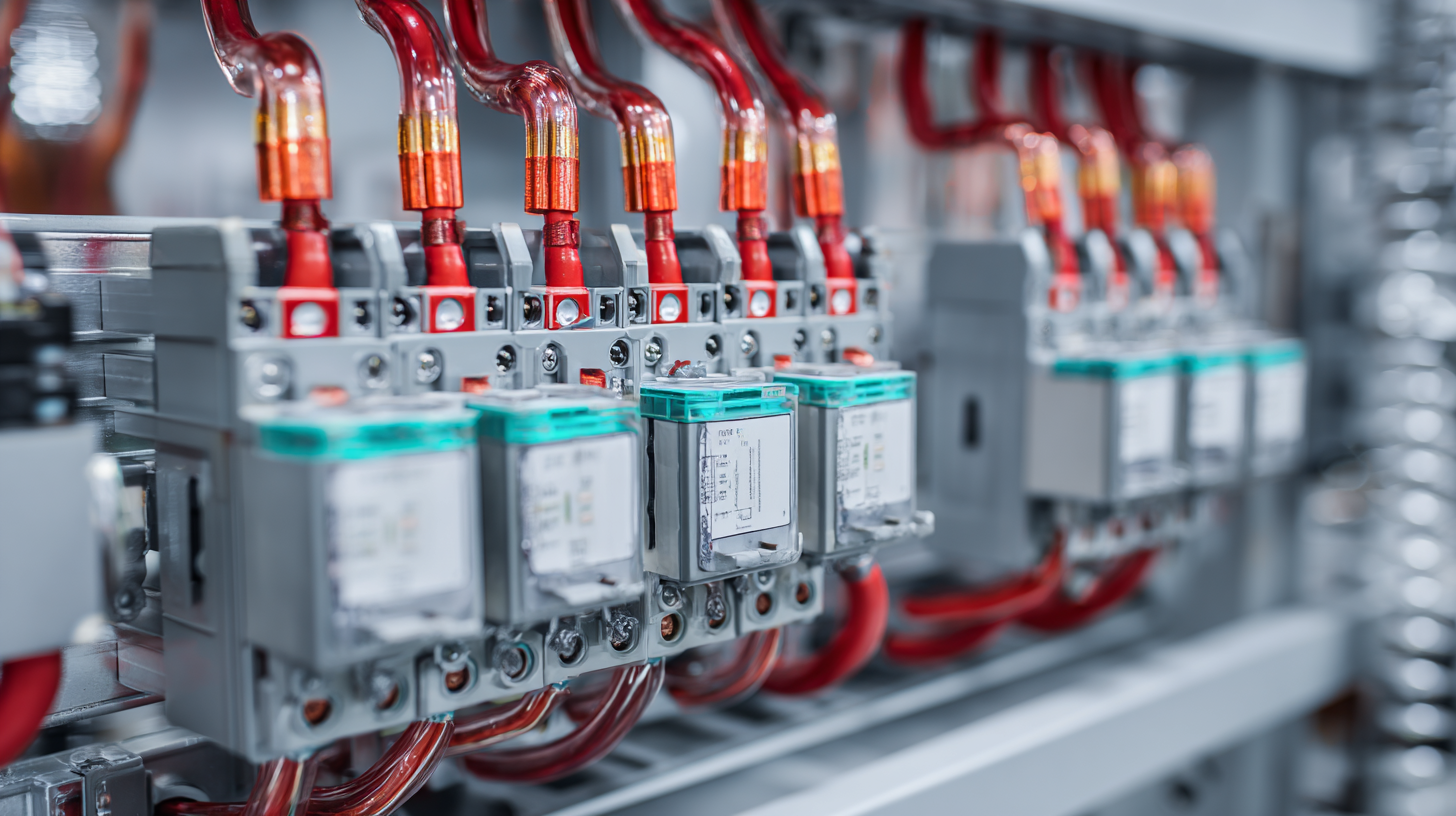

Understanding Flexible Busbar: Definition and Applications

Flexible busbars are pretty much essential in a lot of industrial setups these days. They do a great job of providing reliable electrical connections, even when things are moving around or vibrating — you know, typical in busy environments. Basically, they're conductive pathways that can be bent or twisted to fit just about any space you need. You see them all over, from power distribution systems and renewable energy projects to electric vehicles. And if you check out reports from MarketsandMarkets, they say the global busbar market might hit around USD 18.5 billion by 2026. That’s mainly because there’s more demand for efficient energy delivery and a surge in renewable energy initiatives.

For companies like Sichuan D&F Electric Co., Ltd., which makes electrical connection parts and insulation components, understanding how flexible busbars are used is pretty important. These flexible solutions come with some big perks — like cutting down installation time and reducing maintenance costs. No wonder they’re a popular choice in modern electrical systems.

As the industry keeps shifting and evolving, incorporating flexible busbars into new designs can really boost efficiency — especially in sectors where mobility and flexibility are key. And with advancements in materials and tech, D&F Electric is working hard to offer innovative, tailored flexible busbar solutions that meet the diverse needs of their customers across this rapidly expanding electrical market.

Key Factors in Selecting Flexible Busbar Solutions

When you're picking out flexible busbar solutions for your industrial setup, there are a few important things to keep in mind to make sure everything runs smoothly and stays reliable. First off, you'll want to really think about the electrical load you're dealing with. It’s super important to check the current capacity and voltage levels your system needs. Overloading a busbar isn't just a bad idea — it can cause it to overheat or even fail. So, it's wise to go for a solution that not only meets your current needs but also has a bit of extra capacity just in case.

Next, don't forget about the environment where the busbar will be installed. Is it gonna be exposed to extreme temps, high humidity, or maybe corrosive stuff? Picking the right materials that can handle these conditions is key for making sure your setup lasts and stays safe. Also, think about how much bending the busbar will need — the number of bends and the bending radius matter a lot. If that's not done right, it might cause stress points that could weaken the whole system.

**Some quick tips:**

- Always double-check the manufacturer’s specs to make sure the busbar works well with your electrical setup.

- Don’t hesitate to chat with industry pros — they can give you all sorts of tips on the best materials and designs for your specific needs.

- Keep an eye on your busbar installations over time. Regular checks can help you figure out when maintenance or upgrades are needed, so you stay ahead of any issues.

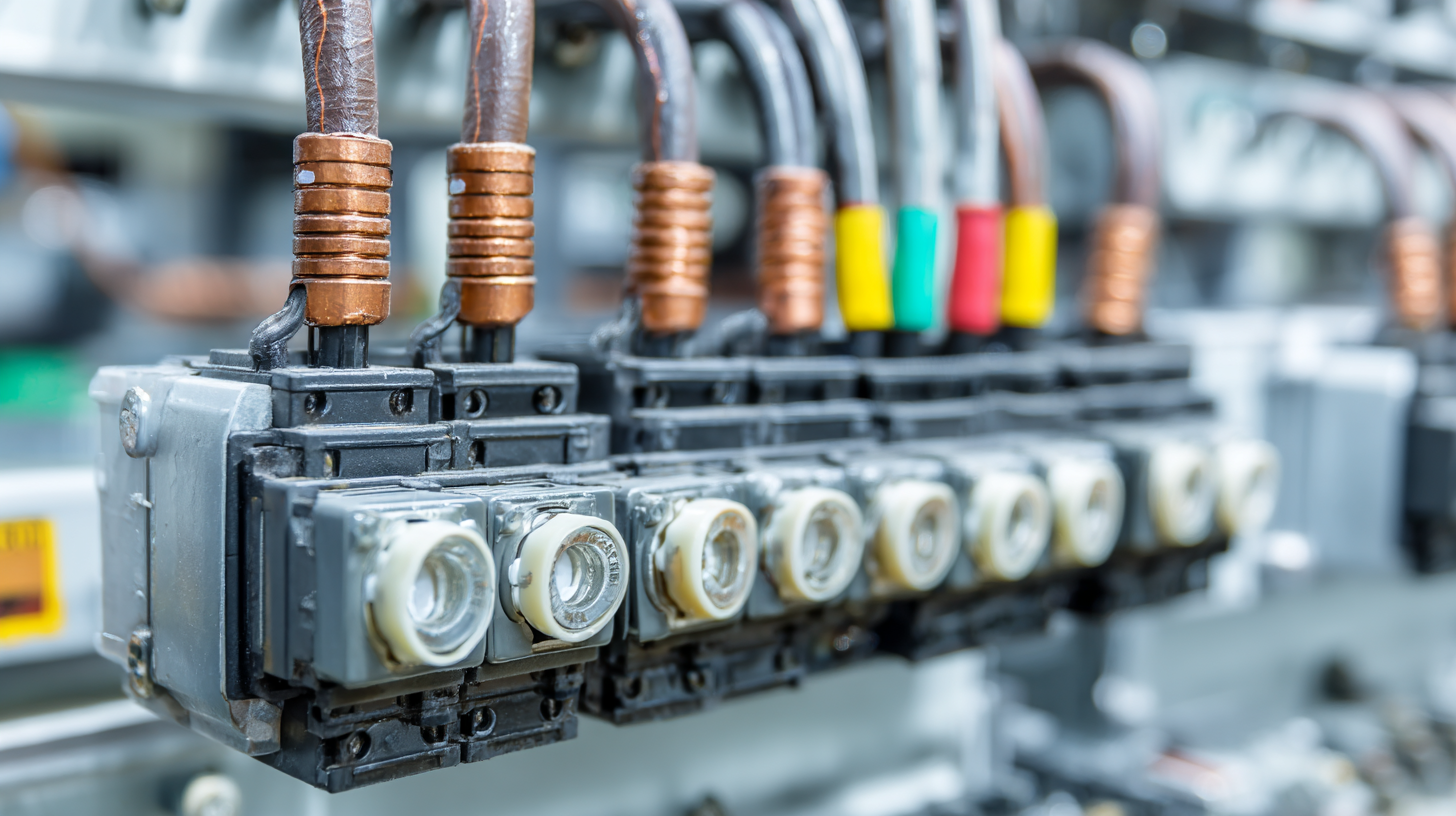

Comparing Materials: Copper vs. Aluminum Busbars

When you're trying to decide between copper and aluminum for busbar solutions, it’s really important to think about their unique material properties and how they perform. Copper, for instance, is known for being tougher—its higher tensile strength often makes it the better choice in more demanding situations. Plus, those intermetallic phases can give copper a real edge, which is why it’s usually preferred when you need long-term reliability and durability in energy systems. Of course, as industrial needs change, your choice of material can also impact costs and how easy or tricky installation might be.

Here are a few pointers to keep in mind: First off, look at what kind of electrical conductivity you need. Copper generally conducts better, but it’s also more expensive, so you’ve got to find a good balance. Next, consider environmental factors and weight restrictions—this is especially important in industries where cutting down weight can really make a difference. And don’t forget to keep an eye on market prices for both copper and aluminum because fluctuations can seriously impact your overall budget. When you weigh these factors carefully, you’ll be better equipped to pick a busbar solution that hits both your performance needs and budget constraints.

Evaluating Electrical Specifications for Your Needs

When you're choosing flexible busbar solutions for industrial setups, it's super important to look at the electrical specs to make sure everything runs smoothly and safely. I came across this report from 2022 by the IEEE, and it says that the demand for these flexible busbar systems is actually expected to grow around 6.5% each year. That's mainly because they're really efficient when it comes to transmitting and distributing power. So, whether it’s the current-carrying capacity, voltage ratings, or how they handle heat — all these specs need to match what your facility needs.

Another thing to think about is what materials are used to make the busbars. Copper’s pretty much the superstar here because it usually conducts electricity way better than aluminum. That’s why it’s often the go-to for high-load stuff. The International Electrotechnical Commission (IEC) even has standards showing that copper busbars can typically handle about 1.5 times the current that aluminum can, given the same cross-section. But, of course, the environment matters too — if your facility's highly humid or filled with corrosive substances, you'll want to pay extra attention to insulation types and durability. By taking all these electrical details into account carefully, businesses can pick the right flexible busbar options that really fit their industrial needs and keep everything running smoothly.

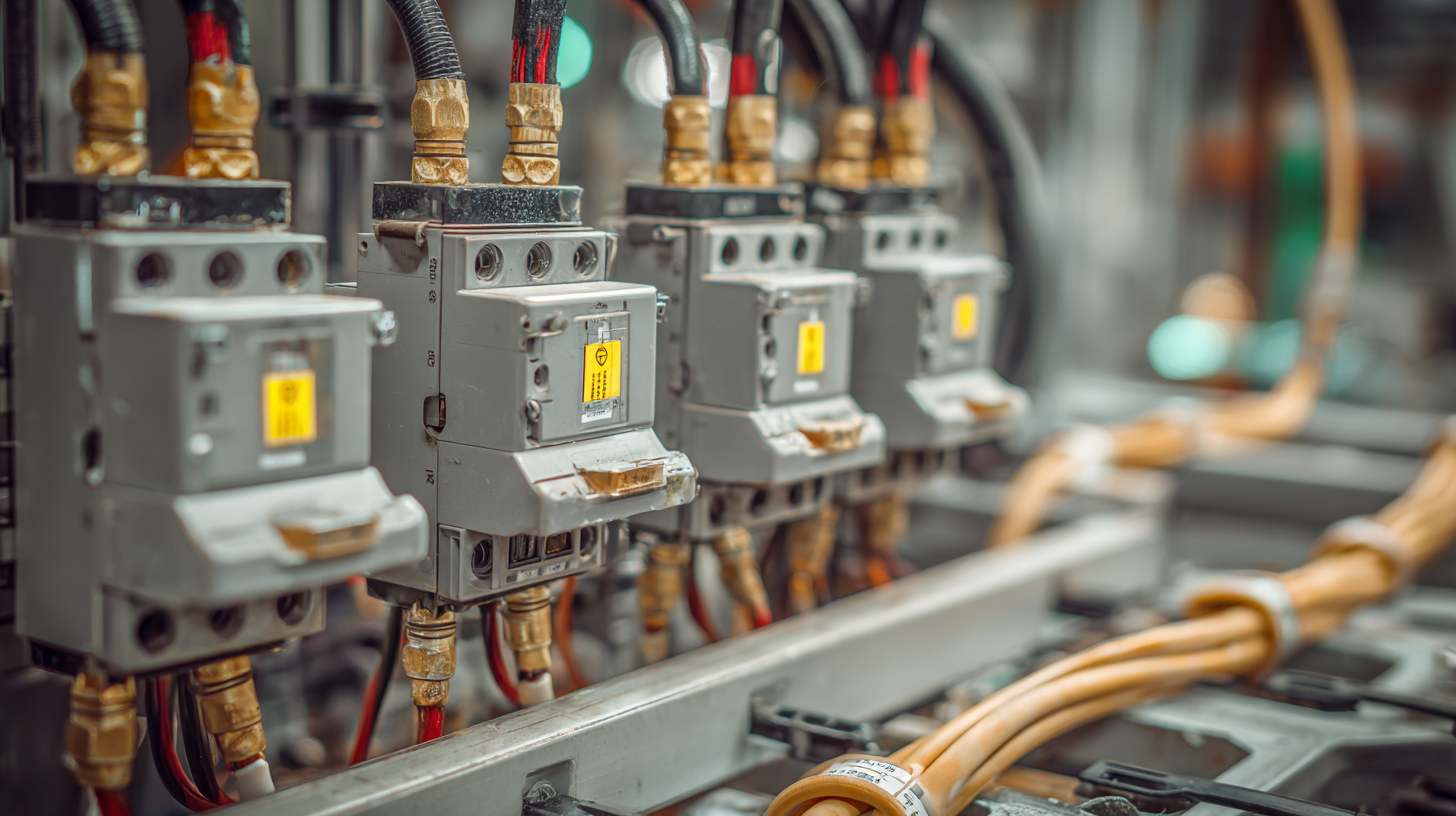

Installation and Maintenance Considerations for Busbar Systems

When you're dealing with installing and maintaining busbar systems, it’s really important to follow good practices to keep everything running smoothly and lasting longer. A top tip? Always stick to the manufacturer’s instructions for installation. That means making sure everything’s aligned properly and connections are tight—this helps dodge electrical issues down the line. And don’t forget, using the right tools during setup can save you from accidentally damaging the busbars or nearby parts.

Keeping up with routine maintenance is just as crucial for your system’s lifespan. I’d recommend checking it out at least twice a year—look for signs of wear, loose connections, or any areas that seem to be overheating. Plus, giving the busbars a good clean, free of dust and dirt, can really boost their efficiency and reliability. A handy tip I’ve come across is using infrared thermography to spot hotspots—those little areas that might be about to cause trouble before things get expensive or dangerous.

And don’t forget, environmental stuff like humidity and temperature swings can impact how well your busbars work. Putting them in ventilated spots and adding protective coatings can make a difference. Keep these tips in mind, and you’ll set yourself up for a reliable, long-lasting setup that really meets your industrial needs.

How to Choose the Right Flexible Busbar Solutions for Your Industrial Needs

| Dimension | Material | Current Rating (A) | Temperature Rating (°C) | Application | Maintenance Frequency |

|---|---|---|---|---|---|

| 30 x 10 mm | Copper | 150 | 75 | Industrial Machinery | Annual |

| 40 x 15 mm | Aluminum | 200 | 80 | Renewable Energy | Semi-Annual |

| 50 x 20 mm | Copper | 300 | 85 | Data Centers | Monthly |

| 25 x 5 mm | Copper | 50 | 70 | Commercial Use | Every Two Years |

Case Studies: Successful Implementations of Flexible Busbars in Industry

These days, with the rise of the Industrial Internet of Things (or IIoT for short), manufacturing is going through some pretty exciting changes. It’s not just about making things more efficient—though that’s a big part of it—but also about sparking innovation across all kinds of industries. When you really dig into it, it becomes clear that IIoT is like the catalyst behind this shift, bringing together cutting-edge tech and helping folks make smarter decisions faster. And now, with this new five-layer architecture for a smart, hierarchical IIoT system, companies can finally find their way through the complicated world of modern manufacturing a bit more easily.

Take, for example, some of the successful projects using flexible busbar solutions—they’re perfect stories that show how big of a difference this stuff really makes. Like, in one recent project with a well-known university, they rolled out some advanced data management tools that seriously boosted what they could do operationally. These flexible busbars weren’t just about quick power distribution—they could also adapt smoothly to the changing demands of the manufacturing setup. Honestly, these kinds of adaptable solutions are key to speeding up the shift toward smarter, more efficient factories. They prove that investing in the right technology isn’t just a fancy move—it actually pays off in real operational improvements and innovation.

Flexible Busbar Solutions in Industrial Applications

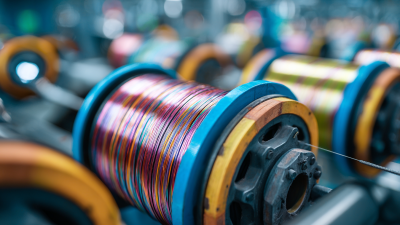

Exploring the Benefits of 6641 F-class DMD Flexible Composite Insulation Paper in Electrical Applications

The 6641 F-class DMD flexible composite insulation paper is a remarkable advancement in electrical applications, providing robust performance and reliability. Comprising a three-layer structure, this insulation paper features a high melting-point polyester film that is sandwiched between layers of polyester non-woven fabric. This design not only enhances its durability but also enables it to withstand high temperatures, making it an ideal choice for various electrical and electronic components.

One of the standout benefits of the 6641 F-class DMD is its exceptional thermal resistance. Rated at Class F, it can function effectively in environments where temperatures reach up to 155°C, ensuring that electrical systems operate smoothly even in the most demanding conditions. The use of Class F adhesive further enhances the integrity of the bond between the polyester film and non-woven fabric layers, leading to a dependable insulation solution that can handle mechanical stresses.

In addition to its thermal properties, the 6641 F-class DMD boasts excellent dielectric strength and moisture resistance, which are crucial for safeguarding electrical components from degradation over time. As industries increasingly demand materials that not only meet but exceed performance standards, the 6641 F-class DMD stands out as a flexible, efficient solution tailored for contemporary electrical applications. Its combination of thermal stability, mechanical strength, and moisture resistance makes it an indispensable asset in the pursuit of reliable electrical insulation.

FAQS

: Always adhere to the manufacturer's installation guidelines, ensure proper alignment, secure connections, and use the right tools and equipment to prevent damage.

Routine maintenance inspections should be scheduled at least twice a year to check for signs of wear, loose connections, and overheating.

Keeping busbars clean and free from dust and debris, as well as using infrared thermography to detect hotspots, can enhance their efficiency and reliability.

Humidity and temperature fluctuations can impact busbar performance, so placing systems in well-ventilated areas and using protective coatings is advisable.

Flexible busbars facilitate efficient power distribution and adapt within evolving manufacturing frameworks, supporting the transition towards smarter manufacturing environments.

IIoT acts as a catalyst for transforming manufacturing processes, integrating advanced technologies and enhancing operational efficiency through smarter decision-making.

Case studies of flexible busbar implementations demonstrate their ability to significantly enhance operational capabilities and support the evolution of manufacturing frameworks.

Regular inspections help identify potential issues such as wear, loose connections, and overheating, which can prevent costly repairs in the future.

Using the right tools and equipment during installation is crucial to prevent damage and ensure secure connections.

Strategic investments in adaptable solutions like flexible busbars can lead to substantial operational advancements and improved efficiency in manufacturing processes.

Conclusion

Hey there! So, in today’s fast-changing world of Flexible Busbars, picking the right solutions really matters if you wanna keep your electrical systems running smoothly across different industrial setups. Basically, this blog is all about demystifying what flexible busbars are and showing you why they’re such a big deal in various industries. We’ll go over some key points to keep in mind when choosing the right busbars, like comparing materials—copper versus aluminum—and why it’s crucial to match the electrical specs to what you actually need.

We’ll also touch on the essential stuff about installing and maintaining these components, so your business can seamlessly incorporate them without headaches. Plus, we’re throwing in some real-life case studies to give you a better idea of how flexible busbars have made a difference in real-world applications. By the way, Sichuan D&F Electric Co., Ltd. is all about providing dependable electrical connection parts, and they’re ready to support you in this lively market. Overall, it’s about helping you understand and make smarter choices so your systems stay efficient and reliable.

Related Posts

-

5 Key Insights on Winding Insulation Class for Optimal Motor Performance

-

The Ultimate Checklist to Choosing the Best Copper Bus Bar for Global Procurement

-

The Ultimate Guide to Laminated Bus Bars for the EV Market: Optimizing Performance and Efficiency

-

Exploring Unique Custom Molding Part Alternatives for Global Buyers

-

Exploring Alternative Options to Best Gpo3 Sheets for Savvy Global Buyers

-

Global Market Insights: Projecting the Future of Best Epoxy Fiberglass Tubes by 2025