5 Key Insights on Winding Insulation Class for Optimal Motor Performance

Table of Contents

- Understanding Winding Insulation Classes and Their Impact on Motor Efficiency

- Comparative Analysis of Different Winding Insulation Materials

- Temperature Ratings and Their Role in Motor Longevity

- Selecting the Right Insulation Class for Specific Applications

- Real-World Examples of Motor Performance Based on Insulation Types

- Best Practices for Maintaining Winding Insulation Integrity

- Elevate Your Electrical Insulation Game with 6641 F-class DMD Flexible Composite Insulation Paper

- FAQS

- Related Posts

Hey, you know, in the world of electric motor design and manufacturing, keeping tabs on Winding Insulation Class is pretty darn important if you wanna get the best performance out of your motors. I mean, industry data shows that around 70% of motor failures happen because of insulation breakdown—so you see just how crucial proper winding insulation is for making motors last longer and run more efficiently.

Oh, and speaking of companies, Sichuan D&F Electric Co., Ltd., was founded back in 2005 and is based in the Jinshan Industrial Park of Deyang, Sichuan. They've really made a name for themselves as a trustworthy supplier of electrical connection parts and insulation components.

By digging into these five key insights about Winding Insulation Class, our goal is to help engineers and techs get a better grip on choosing the right insulation materials—so they can cut down operational risks and make their motors last way longer.

Understanding Winding Insulation Classes and Their Impact on Motor Efficiency

Getting a good grip on winding insulation classes is pretty important if you want your motor to run smoothly and efficiently. Basically, the insulation class assigned to a motor’s windings tells you a lot about how well it can handle heat and how long it’ll last. These classes, usually from A to H, are all about the maximum temperatures the motor can endure—kind of like a thermal limit. Picking the right insulation class isn’t just about reliability; it also helps save energy and cuts down on costs in the long run. Nobody likes wasting energy, right?

And hey, don’t forget about the impact of those sudden voltage spikes—think of them like electrical shocks—that come from inverter-fed motors. Over time, these impulses can do some real damage to the winding insulation if not properly managed. That can lead to insulation failure and, ultimately, a drop in how well the motor performs. So, it’s super important to choose a motor with insulation that can handle these stresses, kind of like giving it a durable shield. Knowing these ins and outs about winding insulation makes a big difference for engineers designing motors that are not only sturdy but also efficient and reliable over the long haul.

Comparative Analysis of Different Winding Insulation Materials

When you're talking about electric motors, the type of winding insulation material you choose really makes a difference in how well the motor performs and how long it lasts. Different materials come with their own perks—some handle heat better, resist electricity more effectively, or stand up to moisture. For example, Class F insulation, which is often made from polyester and polyimide resins, is pretty popular because it can handle higher temperatures without breaking a sweat. That makes it a great pick for motors that have to run in tougher, more demanding environments.

On the flip side, if you need something with even better heat tolerance, epoxy resin-based Class H insulation usually does the trick. It’s great because it stays stable even at really high temps, and its insulating properties are top-notch, so essential parts are less likely to short out or fail. Plus, Class H insulations tend to resist moisture pretty well, making them suitable for motors that are exposed to humid or wet conditions. By understanding the pros and cons of these different insulation materials, manufacturers can make smarter choices. And when they do, it leads to motors that perform better and last longer, which is always a win.

Temperature Ratings and Their Role in Motor Longevity

You know, when it comes to electric motors, the temperature rating of their winding insulation really matters—it's a big deal for how long they last and how well they perform. Insulation classes are kind of like a scoring system that tells you the maximum temperature rise above the normal room temperature the motor can handle. For example, motors with a Class F insulation can usually handle up to 155°C, while those with Class B are a bit more limited, topping out at 130°C. I came across a report from the National Electrical Manufacturers Association (NEMA), and it turns out that if motors stay within their temperature limits, they can last over 20 years easily. But if they run hotter than they should, well, their lifespan can drop way down—sometimes by as much as half. Pretty wild, right?

And it’s not just about the insulation class itself—where and how the motor is used makes a huge difference. In tougher industrial environments, where motors are under heavy loads and face lots of thermal stress, you really want to go for a higher insulation class. Research from the IEEE shows that motors with better insulation not only resist breaking down from heat but also keep their efficiency up. That means lower energy bills and less hassle overall. So, understanding how temperature ratings tie into how long a motor lasts can help engineers pick the right motor for the job and keep things running smoothly for years to come.

Selecting the Right Insulation Class for Specific Applications

Picking the right insulation class for your electric motors isn’t just a technicality — it’s actually pretty key to making sure everything runs smoothly. Basically, the insulation class tells you the max temperature the motor’s windings can handle before something’s gotta give. I read somewhere that, according to the IEC, more than half of motor failures are due to insulation breakdown, which really drives home how important it is to choose the correct insulation for whatever environment and load your motor’s dealing with.

For instance, if you’re working with standard conditions and temperatures stay below 130°C, then Class B insulation should do the trick. But if you’re in a tougher situation — maybe hotter ambient temps or VFD applications — then Class F, rated at 155°C, is usually a safer bet. And here’s a bonus: NEMA points out that going for a higher insulation class can actually make your motors last way longer — sometimes up to 30% more! So, making these smart choices not only boosts how well your motor performs but can also save some serious money on maintenance over time. It’s all about tailoring things to fit your needs, really — giving you a better, more reliable setup in a competitive industrial game.

Real-World Examples of Motor Performance Based on Insulation Types

When you're checking out how well a motor performs, one of the key things to look at is the insulation class of the winding. It’s actually pretty important because it impacts both the efficiency and how reliable the motor is. There are different types of insulation—ranging from Class A to Class H—that can handle various levels of heat, and that really affects how long the motor lasts and how well it runs. For example, Class F insulation can handle temperatures up to 155°C, which makes it a solid choice for tough jobs in industries like automotive and aerospace. A recent study by the Electric Motor Research Institute (EMRI) pointed out that motors with higher insulation classes can be up to 20% more energy-efficient than those with lower ones, especially under the same operating conditions.

When you're checking out how well a motor performs, one of the key things to look at is the insulation class of the winding. It’s actually pretty important because it impacts both the efficiency and how reliable the motor is. There are different types of insulation—ranging from Class A to Class H—that can handle various levels of heat, and that really affects how long the motor lasts and how well it runs. For example, Class F insulation can handle temperatures up to 155°C, which makes it a solid choice for tough jobs in industries like automotive and aerospace. A recent study by the Electric Motor Research Institute (EMRI) pointed out that motors with higher insulation classes can be up to 20% more energy-efficient than those with lower ones, especially under the same operating conditions.

Here's a real-world example that might hit home: an industrial motor with Class B insulation (which can handle up to 130°C) kept failing pretty often when used in a super hot environment. But once they upgraded it to Class F insulation, the motor’s lifespan shot up by over 40%. That kind of upgrade doesn’t just save on maintenance costs; it can also really boost productivity.

Pro tip: When you're picking out motors for specific jobs, make sure to match the insulation class to the temperature environment they'll be working in. It’s a small step that can make a big difference.

And another thing—testing how well different winding materials perform thermally can give you a good idea of how they’ll hold up in real-world conditions. Taking the time to look into these factors early on can lead to serious cost savings and smoother operations down the line.

Another tip: Regular thermal imaging scans are super helpful for catching insulation wear and tear early. Catching these issues before they cause unexpected downtime can save you a lot of headaches.

Best Practices for Maintaining Winding Insulation Integrity

Taking good care of winding insulation is super important if you wanna keep your motor running smoothly. One thing I’d definitely recommend is doing regular insulation resistance tests. It might seem like a small thing, but catching issues early can save you from expensive repairs and unexpected downtime. Just make sure you're using the right testing methods and sticking to industry standards—that way, you’re getting reliable results. Also, don’t forget to think about the environment your motor’s in; if it’s in a place with high humidity or extreme temperatures, you’ll want to check it more often to keep everything in tip-top shape.

Another key step is to have a solid maintenance routine—things like cleaning and inspecting the winding insulation regularly. Dust, moisture, and chemicals can all mess with how well the insulation works, so keeping it clean really helps. Plus, doing thorough inspections can spot wear or damage early on, before things turn into big problems. On top of that, tuning your operating conditions—like reducing electrical and heat stresses—can really help extend the life of the winding insulation and make your motor more efficient overall. If you focus on these maintenance tips, you’ll keep your motor running like a champ and cut down on those nasty surprise failures.

5 Key Insights on Winding Insulation Class for Optimal Motor Performance

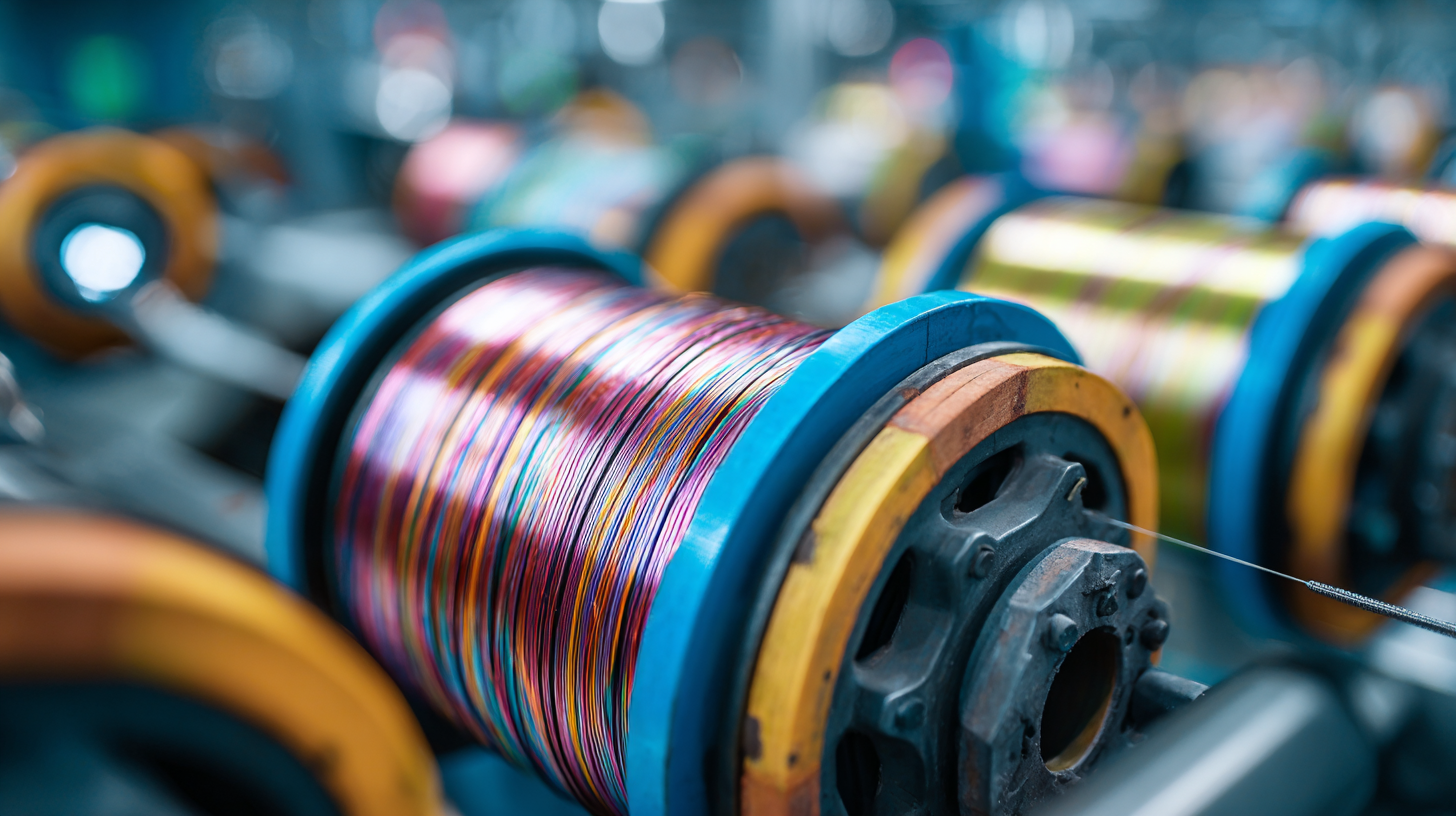

This chart illustrates the performance impact of different winding insulation classes on motor efficiency. Higher insulation classes typically correlate with better performance and longevity in motors.

Elevate Your Electrical Insulation Game with 6641 F-class DMD Flexible Composite Insulation Paper

In the world of electrical insulation, the choice of materials significantly impacts performance and longevity. Elevating your electrical insulation game starts with selecting high-quality insulation papers that can withstand extreme conditions. One standout option is the 6641 F-class DMD flexible composite insulation paper. This innovative insulation solution is engineered for exceptional durability and high thermal resistance, making it ideal for a wide range of electrical applications.

The 6641 DMD insulation paper is constructed with a unique three-layer design, comprising a high melting-point polyester film sandwiched between two layers of polyester non-woven fabric. This configuration not only enhances its mechanical properties but also ensures superior insulation performance. Bound together with Class F adhesive, the 6641 DMD insulation paper meets the stringent demands of F-class thermal applications, allowing for reliable operation in high-temperature environments. Whether you're working on motors, transformers, or generators, incorporating 6641 F-class DMD insulation paper can significantly enhance the reliability and efficiency of your electrical systems.

FAQS

: Winding insulation classes are essential for optimizing motor efficiency and performance. They influence thermal performance and durability, helping to select the right insulation class which enhances reliability and reduces operational costs.

Insulation classes range from A to H, indicating the maximum operating temperatures that the winding can withstand. For example, Class B has a maximum of 130°C, while Class F can operate up to 155°C.

Motors that operate within their temperature ratings can achieve lifespans exceeding 20 years, while those that exceed these limits may experience a significant reduction in service life—up to 50% less.

Impulse voltages from inverter-fed motors can cause accumulated damage over time, potentially leading to insulation failure and decreased motor efficiency, making the choice of appropriate winding insulation crucial.

Choosing the correct insulation class can significantly enhance a motor's longevity, with the National Electrical Manufacturers Association (NEMA) indicating that it can extend operational life by up to 30%.

Matching the insulation class to specific applications ensures optimal performance and prevents insulation breakdown, which accounts for over 50% of motor failures.

Operating motors at high temperatures can lead to thermal degradation, increasing energy consumption and maintenance costs, thus affecting overall efficiency.

Class F insulation is recommended for demanding conditions such as high ambient temperatures or variable frequency drive (VFD) applications.

Motors designed with superior insulation can resist thermal degradation and maintain efficiency, resulting in lower energy consumption and operational costs.

The type of application and operational environment greatly influence the required insulation class, as it determines the maximum temperature the winding can handle before failure occurs.

Related Posts

-

Global Market Insights: Projecting the Future of Best Epoxy Fiberglass Tubes by 2025

-

Exploring Alternative Options to Best Gpo3 Sheets for Savvy Global Buyers

-

Exploring the Unique Properties and Applications of Best Nomex T410 Film: A Comprehensive Guide for Buyers

-

The Ultimate Checklist to Choosing the Best Copper Bus Bar for Global Procurement

-

How to Choose the Best Tin Plated Copper Bus Bar for Your Electrical Needs